Device for suppressing vibration of rolling mill

A rolling mill and vibration signal technology, which is applied in metal rolling, metal rolling, and keeping the rolling equipment in an effective state, etc., can solve the problems of the complex mechanical structure of the rolling mill, affecting the production output and economic benefits, and the many functions of the main drive control system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

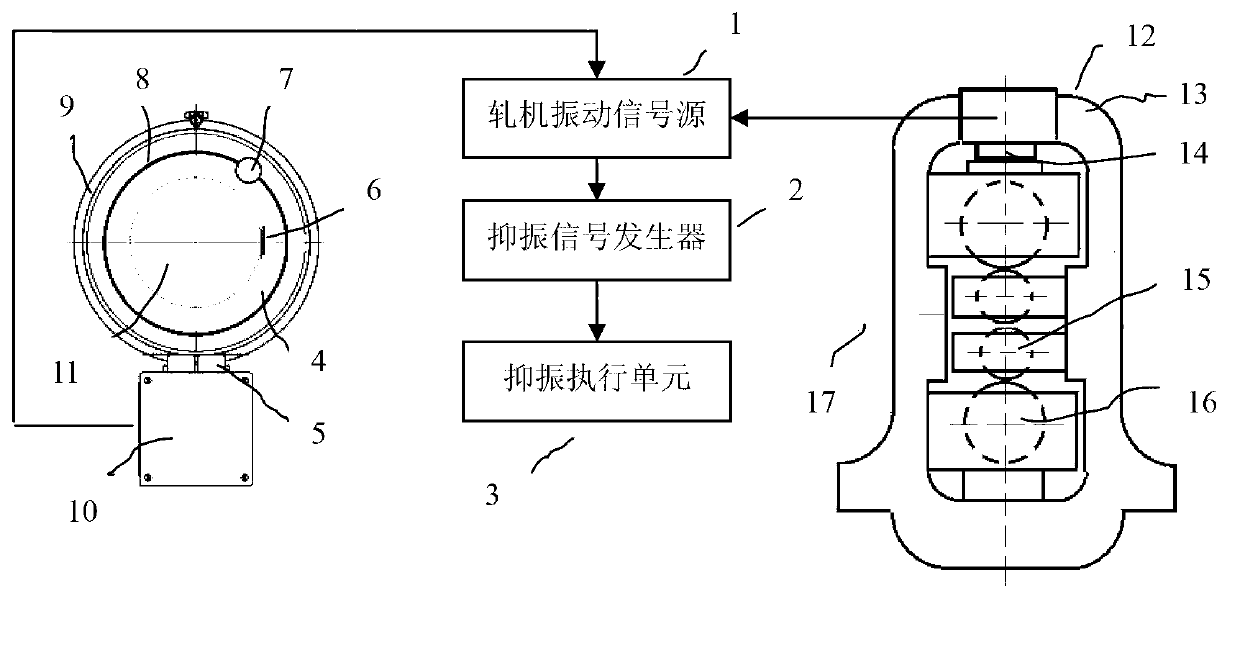

[0018] Such as figure 1 As shown, the structure of the rolling mill vibration suppression device of the present invention is composed of a rolling mill vibration signal source 1 , a vibration suppression signal generator 2 , a vibration suppression execution unit 3 and a rolling mill 12 .

[0019] When the rolling mill vibrates, the signal from the rolling mill vibration signal source 1 is introduced into the vibration suppression signal generator 2 to generate a vibration suppression damping signal, and the vibration suppression execution unit 3 is used to suppress the vibration of the rolling mill 12 .

[0020]

[0021] Such as figure 2 As shown, the principle of the present invention is that when the rolling mill is rolling a strip with thin gauge or large deformation resistance, the rolling mill will vibrate strongly. At first pick up the rolling mill torsional vibration signal, the rolling speed signal, the rolling mill vertical vibration signal and the rolling pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com