Screwdriver head push-pull type disassembling tool

A bit push-pull type tool technology, used in power tools, manufacturing tools, wrenches, etc., can solve the problems of difficult alignment of placement holes and screw bit fixing tubes, inconvenient switching operations, and inconvenient storage of bit heads. Easy to store batch heads, simple structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

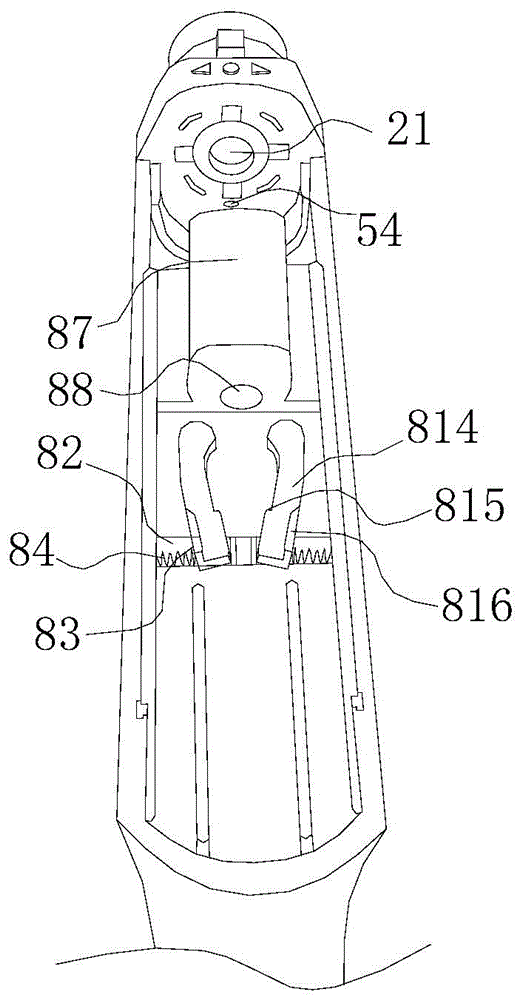

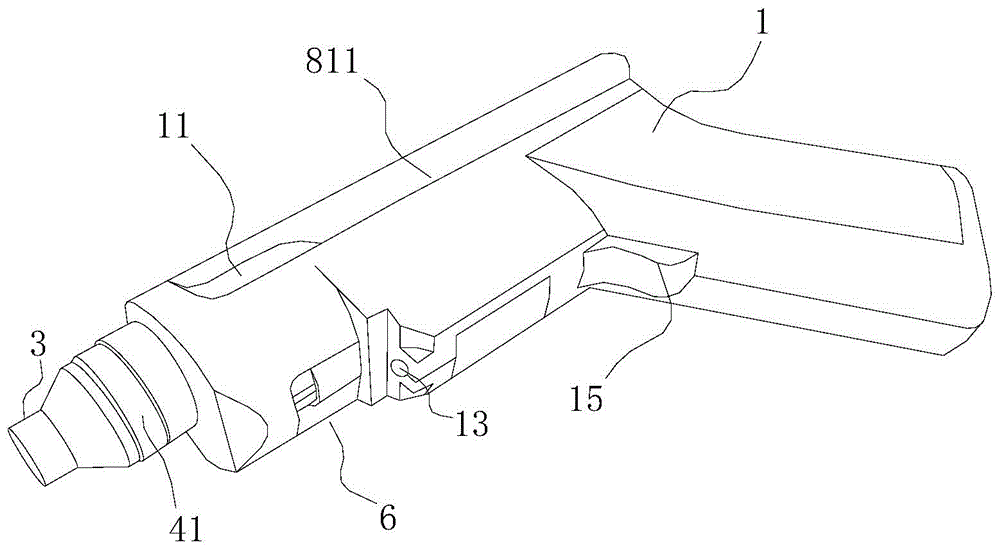

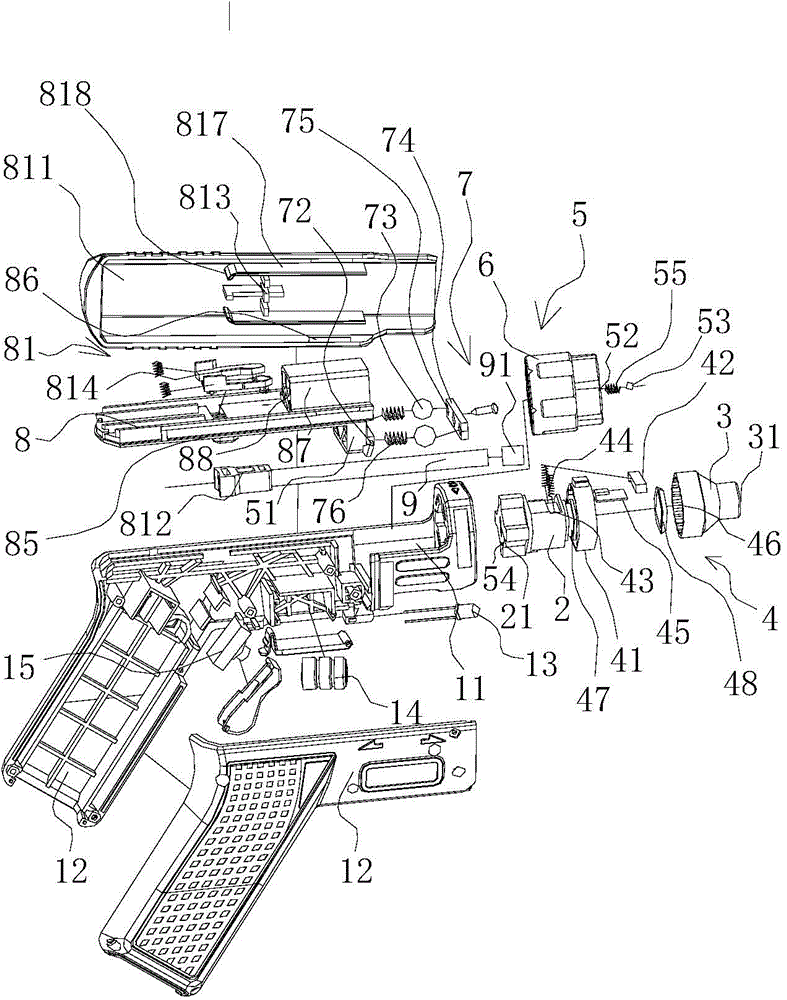

[0024] Such as Figure 1-4 As shown, the batch head push-pull disassembly tool includes a housing 1, the end of the housing 1 is provided with a ratchet seat 2 with a conveying channel 21, and the ratchet seat 2 is provided with a bit that communicates with the conveying channel 21. The ratchet head 3 of the installation hole 31 is provided with a ratchet control mechanism 4 for controlling the circumferential rotation direction of the ratchet head 3 and / or circumferentially locking the ratchet head 3 between the ratchet head 3 and the ratchet seat 2; The storage slot 11 is provided with a bit storage seat 6 which can rotate in the circumferential direction through the installation structure 5 in the storage slot 11. The bit storage seat 6 has a number of bits arranged axially along the bit storage seat 6 and used for storing batches....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com