Gear shaft pressing clamp

A technology for gear shafts and fixtures, which is applied in the manufacture of tools, workpiece clamping devices, metal processing, etc., can solve the problem of no mechanism to detect the verticality of gears and shafts, so as to avoid scrapping, improve the pass rate, and good positioning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

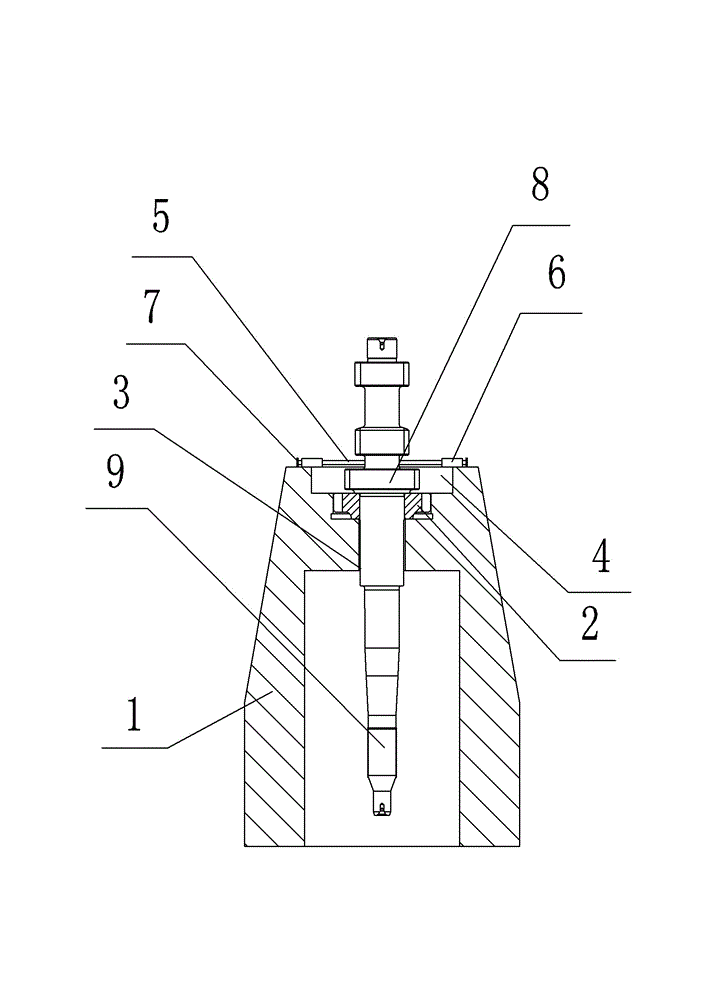

[0014] The reference signs in the drawings of the specification include: base 1 , positioning ring 2 , through hole 3 , groove 4 , detection rod 5 , positioning block 6 , safety pin 7 , gear 8 , and shaft body 9 .

[0015] Such as figure 1 As shown, a gear shaft pressing fixture in this embodiment includes a base 1 and a positioning ring 2. The base 1 is provided with a through hole 3 for accommodating the shaft body 9 and a groove 4 for accommodating the gear 8. The positioning ring 2 is provided with in groove 4. It also includes a guide device arranged on the base 1 opposite to the center of the through hole 3 , the guide device includes a detection rod 5 , a positioning block 6 located above the groove 4 and a safety pin 7 . There is a through hole 3 in the positioning block 6, and the detection rod 5 is movably connected in the through hole 3. The end of the detection rod 5 close to the shaft body 9 extends to the theoretical outer contour of the shaft body 9, and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com