Tool changing post

A tool holder and fixture seat technology, which is applied in the field of tool changer, can solve the problems of cumbersome tool change process, difficulty in ensuring the coaxiality of hole machining, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

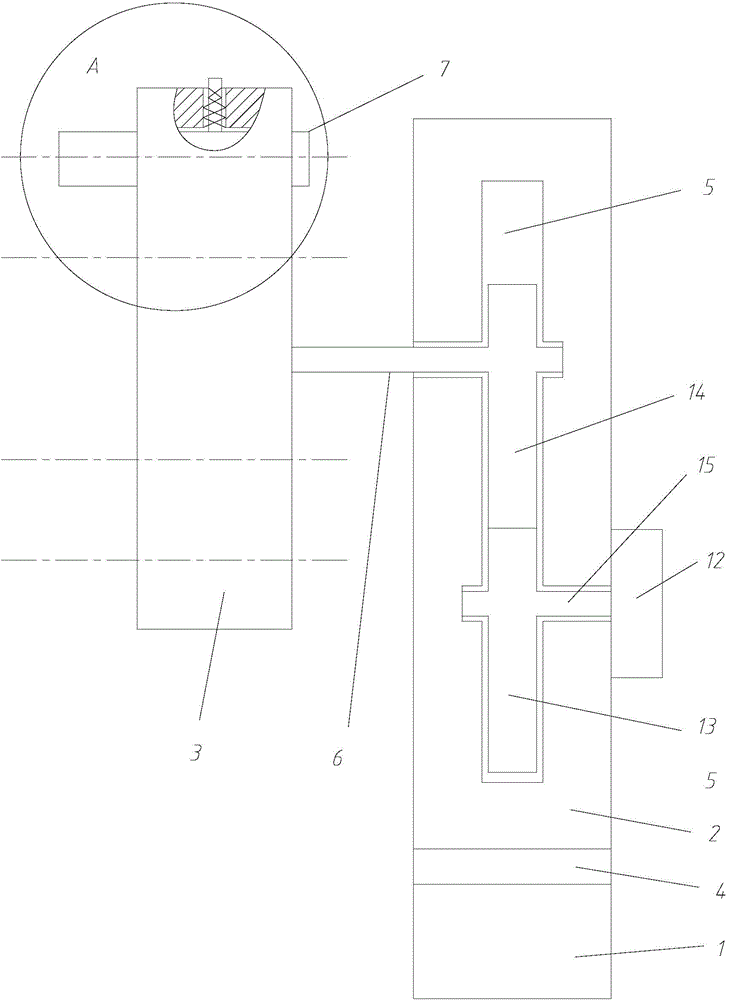

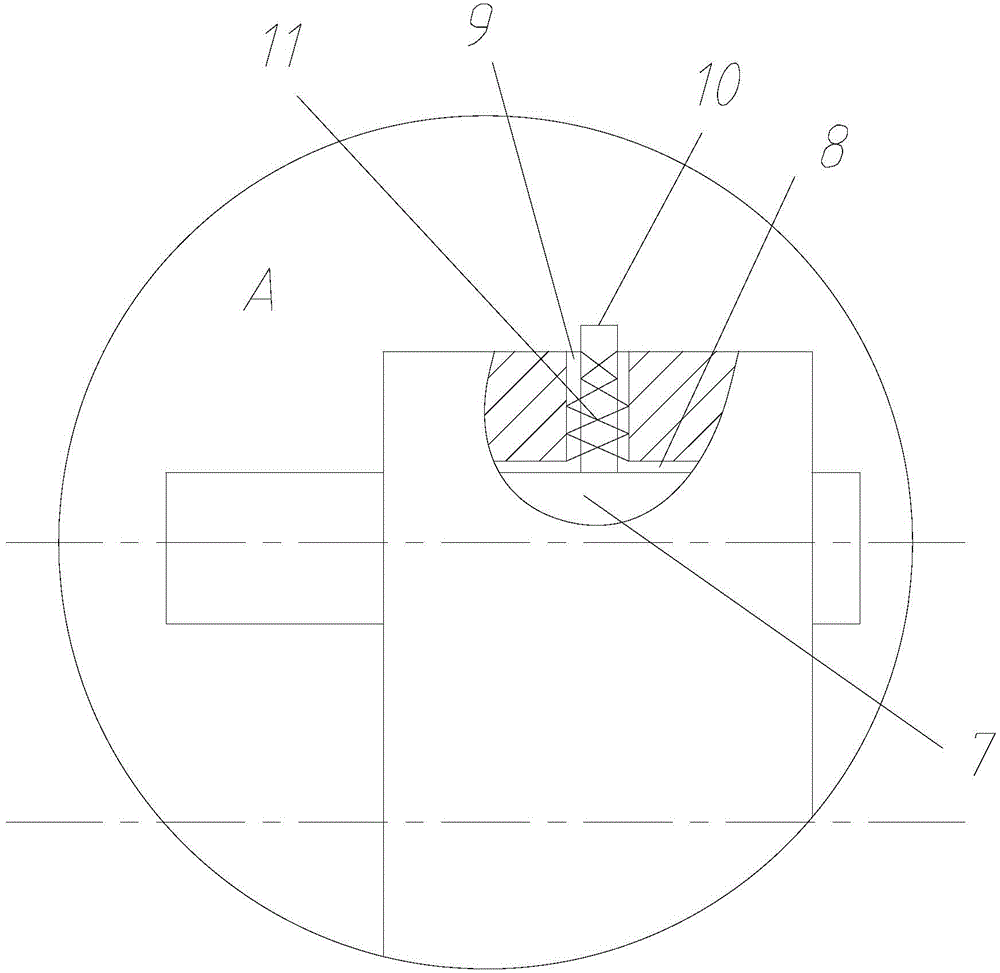

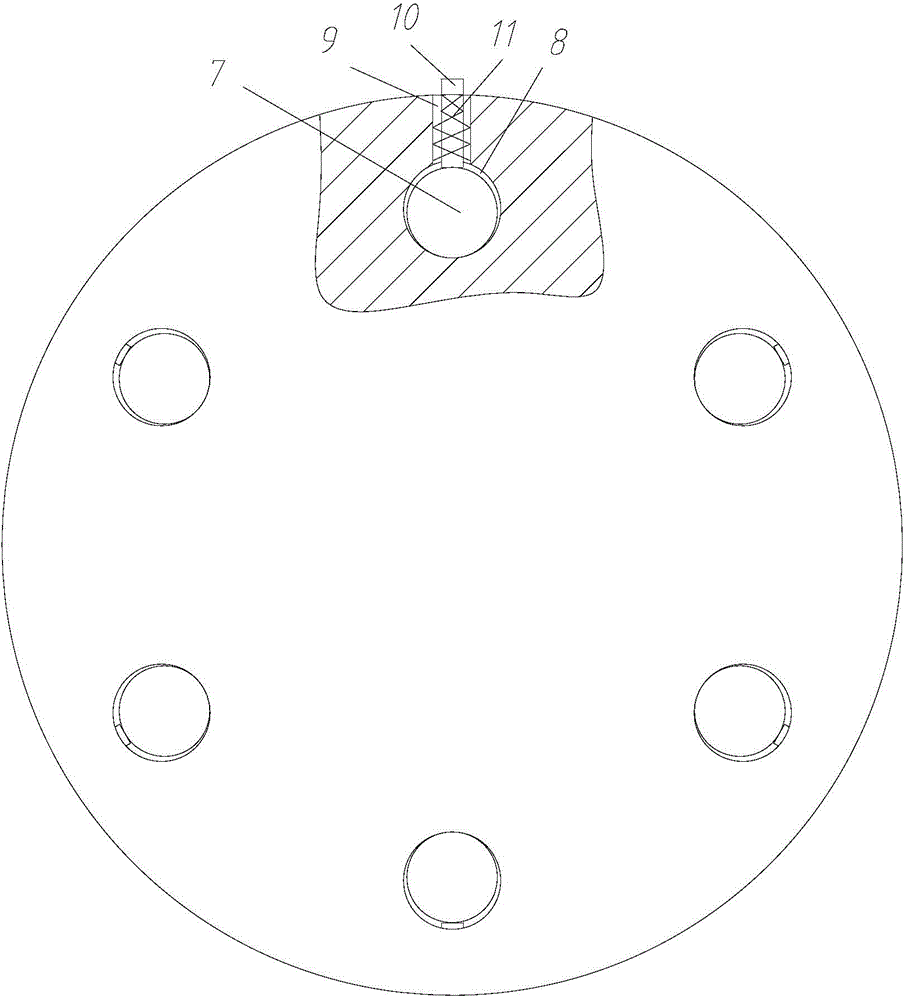

[0016] see Figure 1~3 , a tool changer, comprising a base 1 that can move back and forth, left and right, a fixture seat 2 that can move up and down on the base, and a rotatable fixture 3 that is arranged on one side of the fixture seat. There is a lifting mechanism 4 connected between them, the interior of the clamp seat is provided with an accommodating cavity 5 for accommodating the transmission mechanism, and the side wall on one side of the clamp seat is provided with a transmission shaft 6 connected with the transmission mechanism, and the clamp is cylindrical , the fixture is provided with a number of axially arranged through holes 8 for placing the cutter 7, the through holes are evenly distributed around the axis of the fixture, the side wall of the fixture is provided with a locking mechanism for locking the cutter, the fixture and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com