Automatic brazing material paving and spot welding system and control method thereof

A brazing material and spot welding technology, which is applied in the field of metal resistance welding, can solve problems such as difficulties and achieve the effects of prolonging service life, realizing positioning, improving adaptability and automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

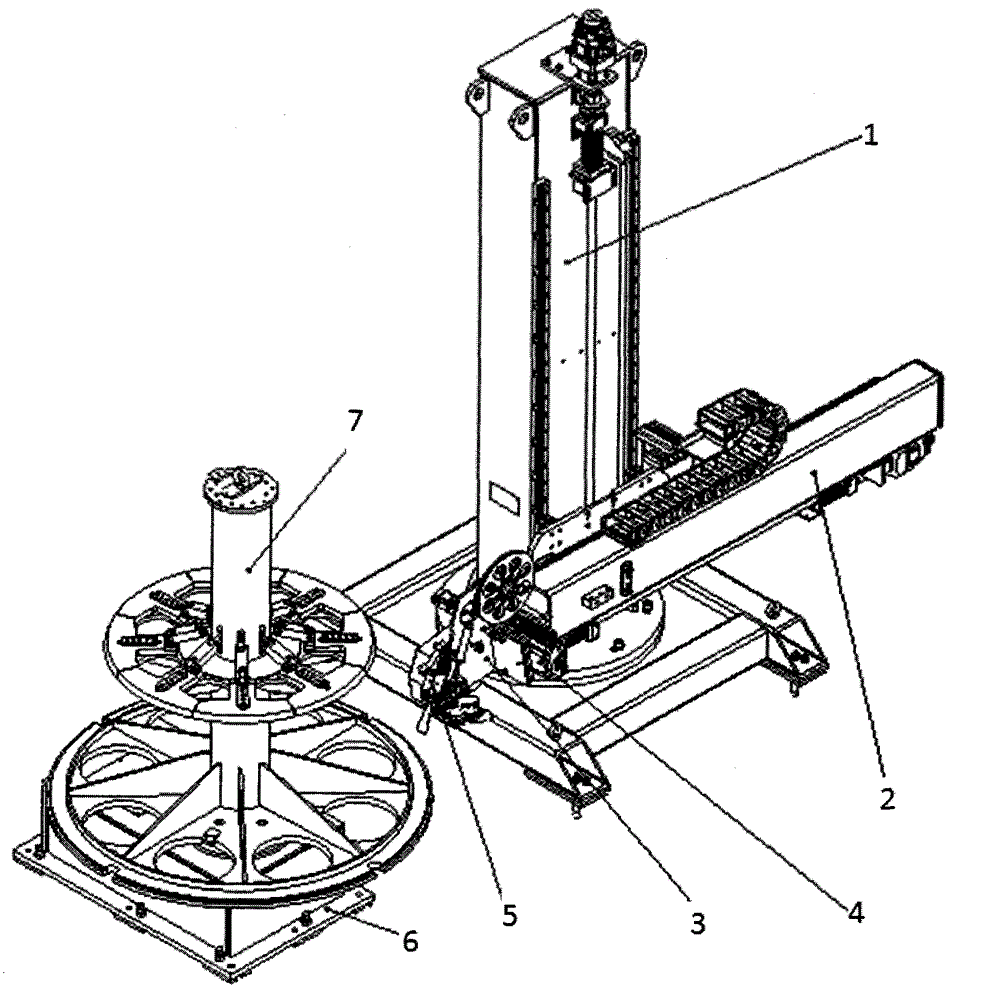

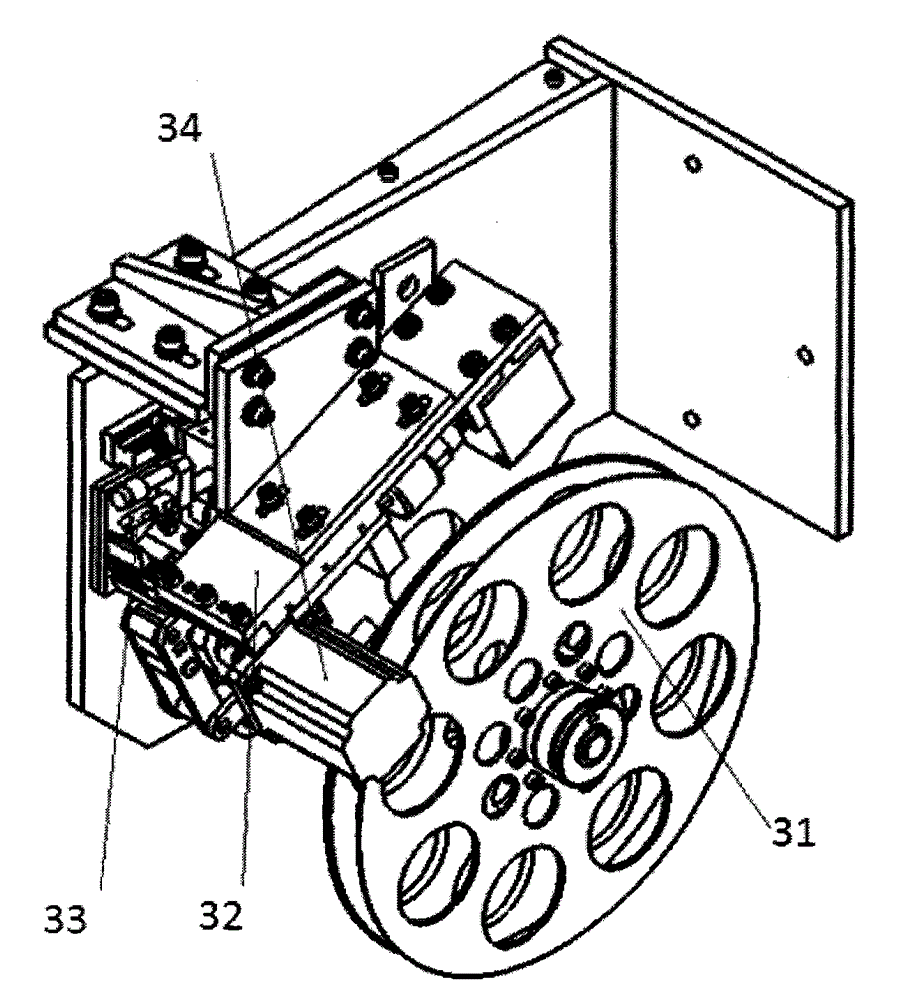

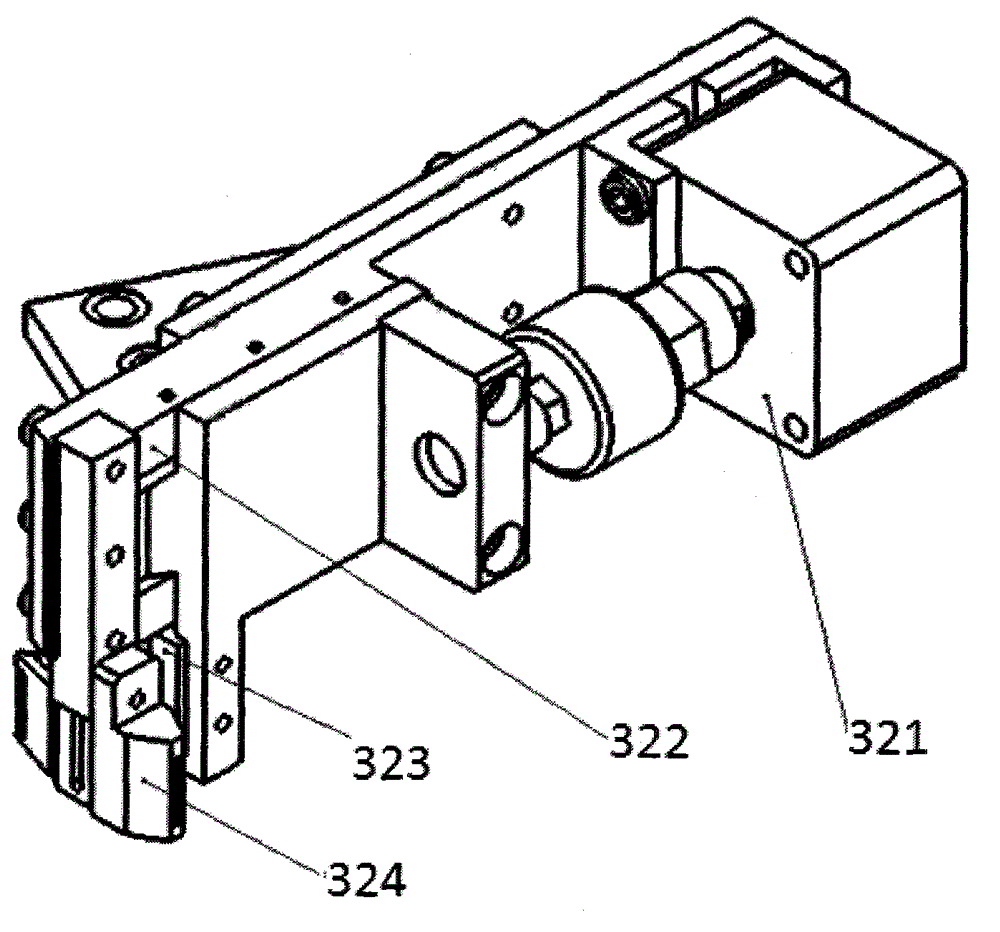

[0043] Combine below Figure 1 to Figure 8 , the present invention is further described:

[0044] Such as figure 1 As shown, an automatic brazing material laying spot welding system includes a column 1, a moving beam 2, a spot welding head 3, a horizontal slide 4 and a turntable 6. One end of the moving beam 2 is connected to the spot welding head 3; the moving beam 2 moves horizontally on the column 1 driven by a servo motor, and the moving beam 2 moves vertically on the column 1 driven by another servo motor; The spot welding head 3 moves horizontally on the horizontal sliding table 4 driven by the third servo motor; the tooling 7 is arranged on the rotary table 6, and the welding workpiece is fixed on the tooling 7, and the tooling 7 and the rotary table 6 pass through the fourth servo Rotate driven by motor.

[0045] The moving beam 2 can move horizontally or vertically, and is driven by a servo motor, which is controlled by a CNC numerical control system. Different pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com