Laying process of geotechnical cloth under high-pile wharf

A high-pile wharf and geotextile technology, which is applied in soil protection, sea area engineering, water conservancy projects, etc., can solve the problems of geotextile sliding, long time interval of geotextile, easy aging, etc., and achieve smooth laying, good laying effect, The effect of not being able to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

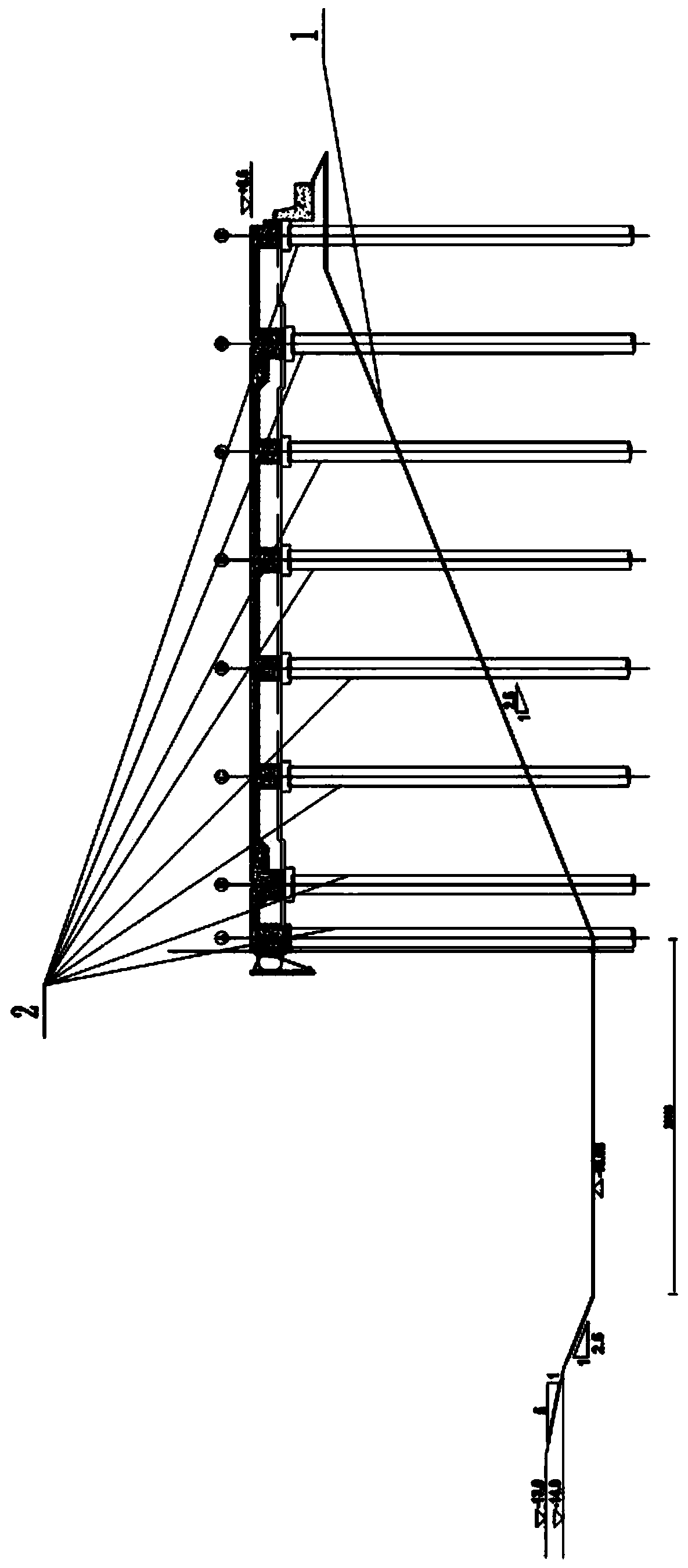

Image

Examples

Embodiment 1

[0040] Embodiment 1 A laying process of geotextiles under a high pile wharf, comprising the following steps:

[0041] (1) Cutting: Geotextile 1 is made in two forms, one is the geotextile roll between odd-numbered racks; the other is the overlapping fabric roll between two adjacent geotextile rolls;

[0042] (2) Preliminary preparation: Roll out the geotextile on the ground, cut a round hole at the two steel piles at the row G and row B corresponding to the even pile position according to the drawing size, and then use two 20m long nylon Tie the two corners of one end of the geotextile roll firmly with the rope, and tie the other ends of the two nylon ropes to the cloth roll, and then turn the roll to roll the geotextile neatly on the roll;

[0043] (3) Positioning: Place the cloth rolling roller on the positioning buoy, drag the positioning buoy to the parking position at the front of the wharf, and after positioning the buoy, it is parallel to the parking barge. The parking ...

Embodiment 2

[0056] Embodiment 2 A laying process of geotextiles under a high pile wharf, comprising the following steps:

[0057] (1) Cutting: Geotextile 1 is made in two forms, one is the geotextile roll between odd-numbered racks; the other is the overlapping fabric roll between two adjacent geotextile rolls;

[0058] (2) Preliminary preparation: Roll out the geotextile on the ground, cut a round hole at the two steel piles at the row G and row B corresponding to the even pile position according to the drawing size, and then use two 20m long nylon Tie the two corners of one end of the geotextile roll firmly with the rope, and tie the other ends of the two nylon ropes to the cloth roll, and then turn the roll to roll the geotextile neatly on the roll;

[0059] (3) Positioning: Place the cloth rolling roller on the positioning buoy, drag the positioning buoy to the parking position at the front of the wharf, and after positioning the buoy, it is parallel to the parking barge. The parking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com