A device for overhauling the inner wall of a ball mill barrel

A technology for overhauling devices and barrels, which is applied in grain processing and other directions, can solve problems such as shortening repair time, and achieve the effect of reasonable structure and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

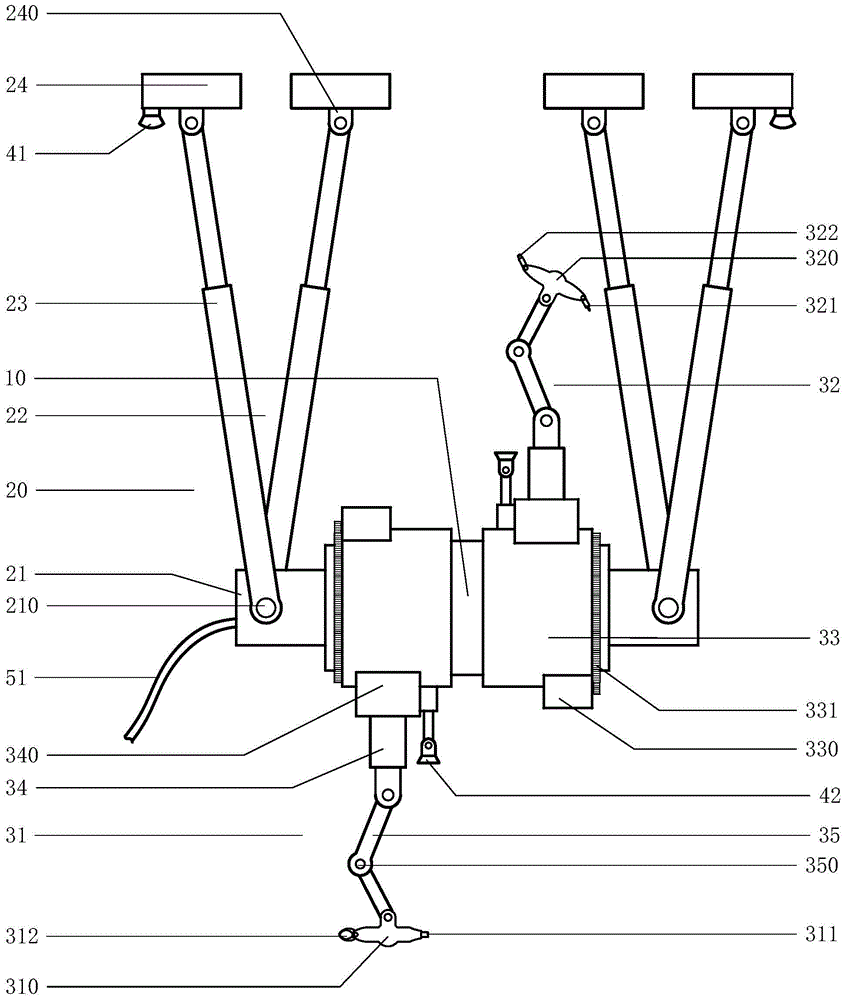

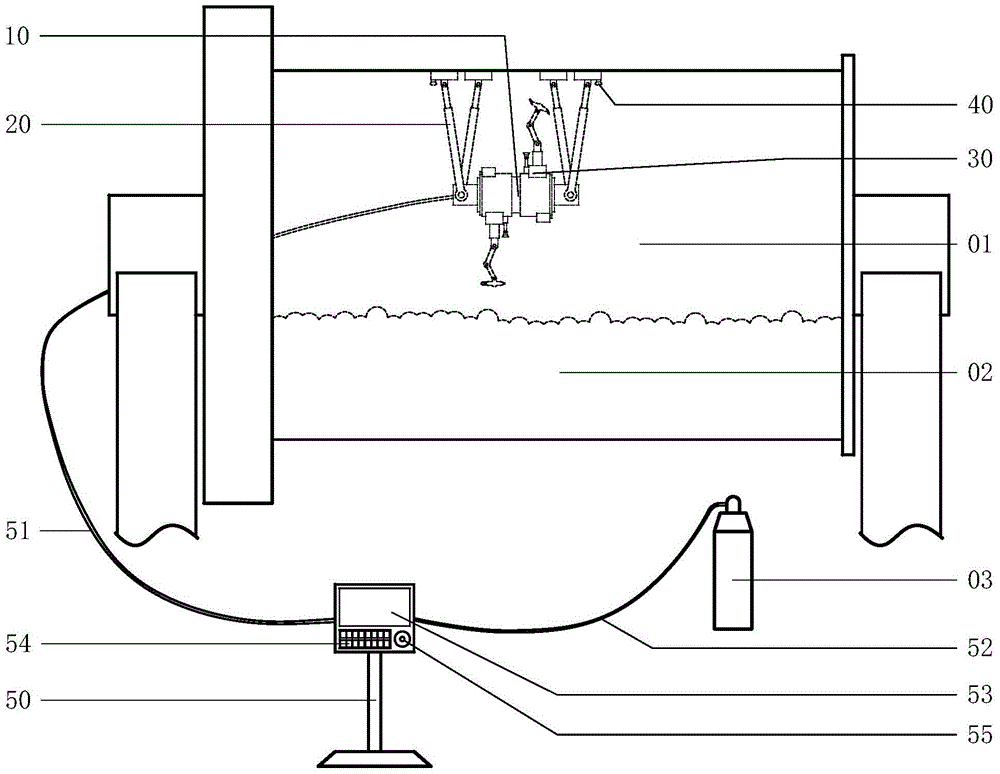

[0018] see figure 1 and combine figure 2 , the maintenance device for the inner wall of the ball mill cylinder in this embodiment includes a comprehensive frame 10, a suspension walker 20, a liner maintenance arm 30, a lighting and camera system 40, and a remote control console 50, and a hydraulic drive machine is arranged inside the comprehensive frame 10. And integrated power distribution system, all are provided with suspension walker 20 at both ends of integrated frame 10, and described suspension walker 20 comprises straddle drive machine 21 and suspend stride bar 22, and described suspension stride bar 22 comprises two pairs of Telescopic hanging rod 23, described two pairs of telescopic hanging rods 23 are respectively installed on the two sides of span rod driver 21, and the ends of every pair of telescopic hanging rods 23 are provided with electromagnetic suckers 24; Arm 31 and welding and cutting rocker arm 32 are also installed in the middle part of comprehensive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com