Work-piece welding turnover device

A technology for turning over devices and workpieces, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high technical level requirements of welding workers, affecting the quality of workpieces, and accumulation of welding ash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Hereinafter, the present invention will be further explained in conjunction with the accompanying drawings of the specification.

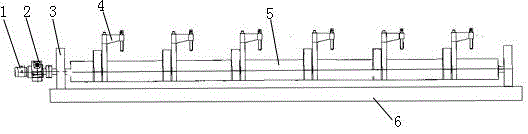

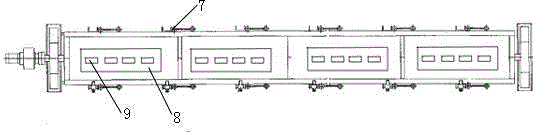

[0011] As shown in the figure, a workpiece welding and turning device includes a lifting platform 6, a fixed seat 3 is fixed on the lifting platform 6, a turning table 5 is set on the fixed seat 3 to rotate and cooperate, the turning table 5 is connected to the reducer 2, and the reducer 2 is connected to the motor 1. Therefore, driven by the motor 1, the turning table 5 can be turned at any angle. A set of first pneumatic pressing mechanism 4 and a set of second pneumatic pressing mechanism 7 are fixedly arranged on both sides of the turning table 5, and the first pneumatic pressing mechanism 4 and a set of second pneumatic pressing mechanism 7 are used for clamping the workpiece. An air blowing mechanism 8 is provided in the middle of the turning table 5, and the air blowing mechanism 8 is connected with an air hole 9 provided on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com