Core box for high-precision assembly foundry

A high-precision, core box technology, which is applied in the direction of casting and molding equipment, can solve the problems of easy deviation of the concentricity of the mold and poor coaxiality of the core box, and achieve the goals of preventing mutual rotation, ensuring precision and improving combination precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

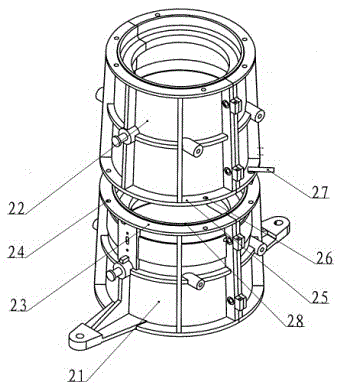

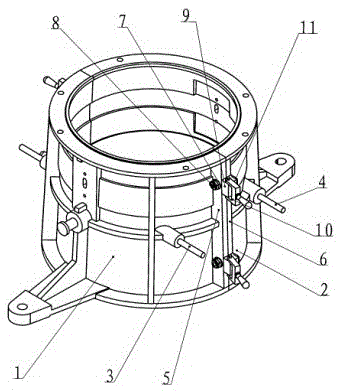

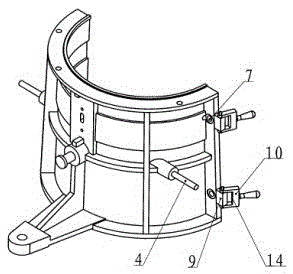

[0014] A core box for high-precision assembly casting, including a first core box unit 21 and a second core box unit 22, the first core box unit 21 and the second core box unit 22 have the same structure, and the first core box unit 21 is Composed of a left half core box unit 1 and a right half core box unit 2, the left half core box unit 1 is provided with a left separation buckle handle 3, and the right half core box unit 2 is provided with a right separation buckle handle 4 , it is convenient to fasten or separate the two half-core box units by separating the fastening handle. The left half-core box unit is combined with the left half-core box unit on its outer edge and the outer edge of the right half-core box unit. The right half core box unit on the top is fastened together with the vertical rib plate 6, and a positioning pin hole 7 is arranged on the left half core box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com