A self-centering universal closing tool for self-locking nuts

A self-locking nut and self-centering technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of easy breakage of the closing block and the base of the closing table, affecting the closing accuracy, etc., to achieve simple structure and strong applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

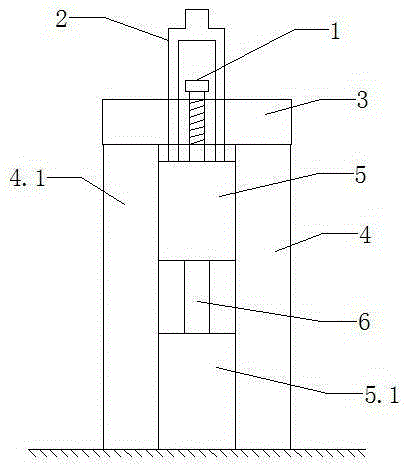

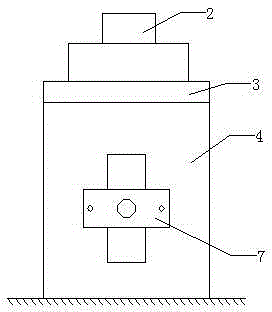

[0021] Embodiment 1: as attached figure 1 , 2 , a self-centering universal closing tool for self-locking nuts, including an adjusting screw 1, a pressure plate 2, a top plate 3, a front side plate 4, a rear side plate 4.1, an upper die 5 and a lower die 5.1, and the pressure plate 2 passes through the top plate The rectangular hole on the 3 gives the stamping force of the upper die 5; the upper part of the pressing plate 2 is connected to the power source, and the lower part is fork-shaped. The adjusting screw 1 passes through the threaded hole of the top plate 3 to adjust the height of the upper die 5. The upper die 5 is also provided with an elastic support (not shown in the figure) supported on the side plate or the lower die 5.1, and the adjusting screw 1 is rotated. The upper die 5 can be moved up and down relative to the top plate 3 . The front side plate 4 and the rear side plate 4.1 clamp the upper die 5 and the lower die 5.1, and the front side plate 4 middle part i...

Embodiment 2

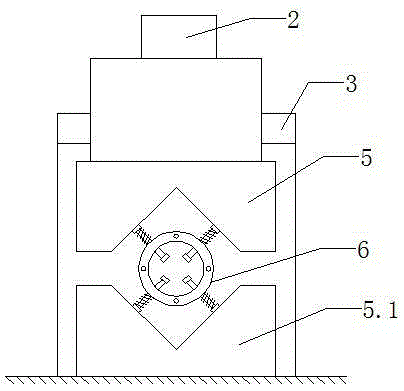

[0024] Embodiment 2: as Figure 4 , the gaps of the upper die 5 and the lower die 5.1 are in the shape of a vertical arc with a high line; the closing blocks 6.2 are three to six, which are axisymmetric with respect to the vertical axis of the upper die 5 and the lower die 5.1 Arrangement, its closing process is similar to embodiment 1. The circular arc shape of the die surface gap needs to be slightly elliptical according to the range of the workpiece. During the up-and-down movement of the upper die 5, the closing block 6.2 compresses the spring 6.3, further inserts the seat ring 6.1, and moves along the circular arc die face apex. During this process, the closing block 6.2 is basically perpendicular to the mold surface. When there are three, five, or six closing blocks 6.2, some of them are on the high line of the curved mold surface, and the closing block 6.2 is pressed against the center of the seat ring 6.1 to make the closing The forming block 6.4 at the front end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com