Steel structure roof ETFE buckle type PVC film closing construction method

A technology of ETFE membrane and construction method, which is applied in the direction of roof insulation materials, roofing, roof covering, etc., can solve the problems of water seepage on steel structure roofs, achieve the effects of reducing wrinkles, reducing labor intensity, and improving closing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

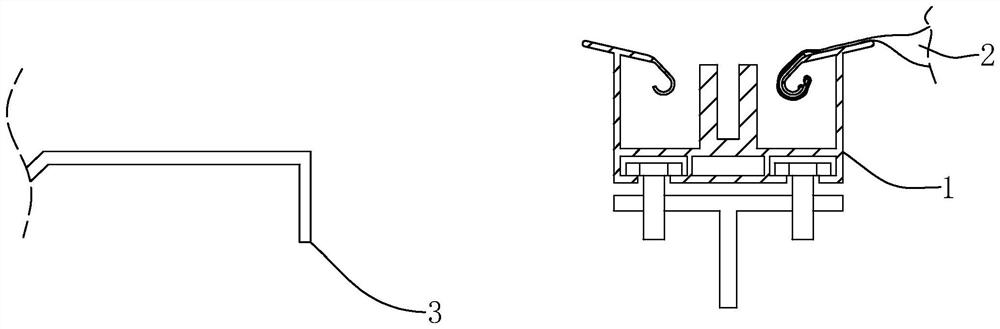

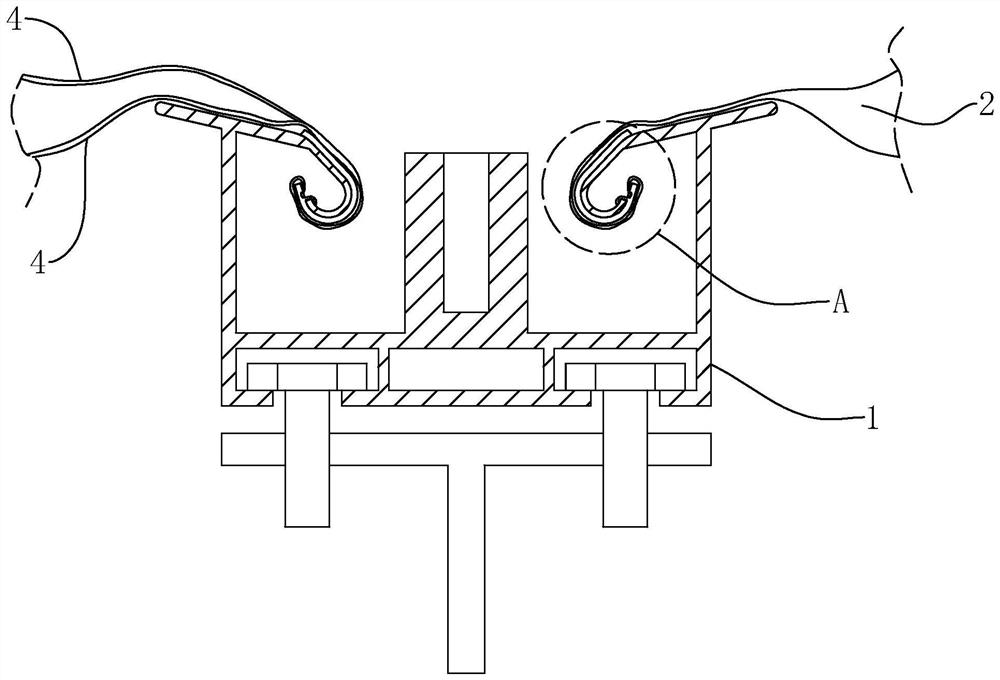

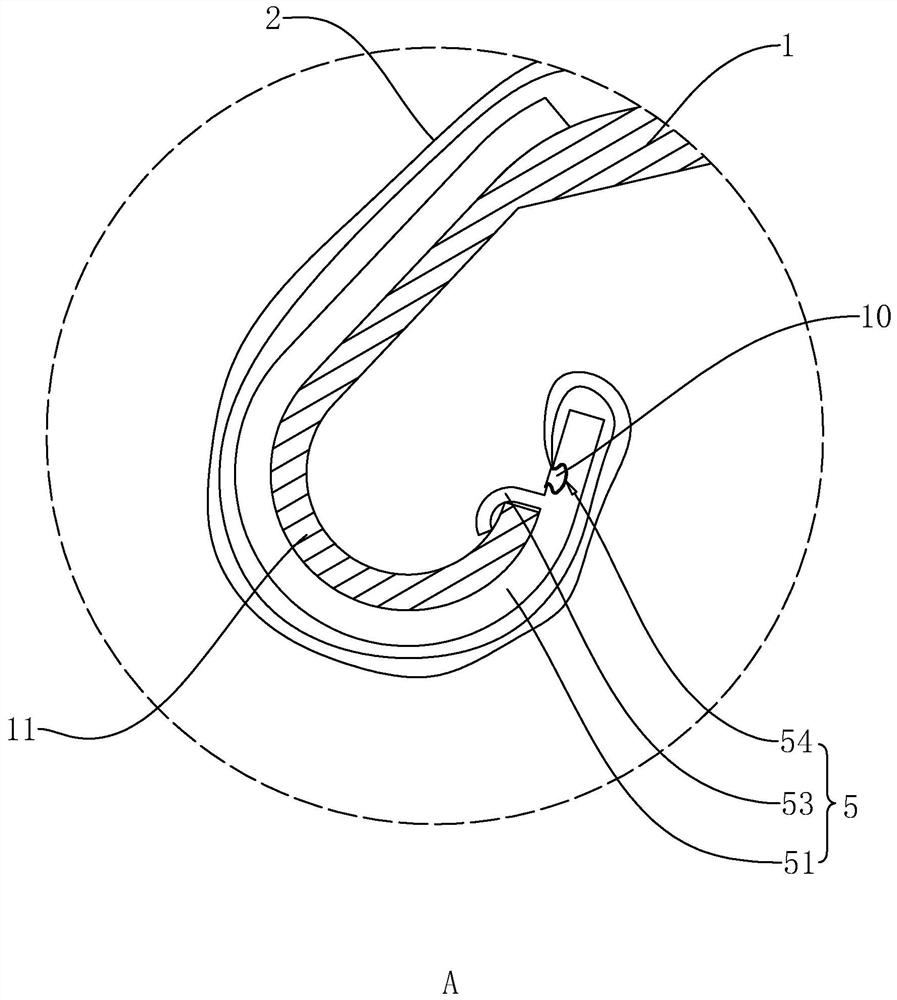

[0042] The following is attached Figure 1-6 The application is described in further detail.

[0043] The steel structure canopy mainly includes a large-span steel structure support frame, ETFE membrane laid on the steel structure support frame and decorative aluminum plate connected with the steel structure support frame, and the ETFE membrane forms the roof of the steel structure. After the ETFE film is laid on the steel structure support frame, the edge of the ETFE film is pressed and fixed on the surface of the decorative aluminum plate with an aluminum strip, and the closing operation of the ETFE film can be completed.

[0044] The embodiment of the present application discloses a construction method for closing the ETFE snap-fit PVC membrane on a steel structure roof, which is used to improve the water seepage problem easily caused by the closing gap between the ETFE membrane on the steel structure roof and the decorative aluminum plate.

[0045] refer to Figure 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com