Paint spraying room with deslagging function

A paint spray booth and functional technology, applied in the field of paint spray booths, can solve the problems of collapse of the environmental protection system, heavy load of the environmental protection treatment system, etc., and achieve the effects of ensuring safe treatment, high slag scraping efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

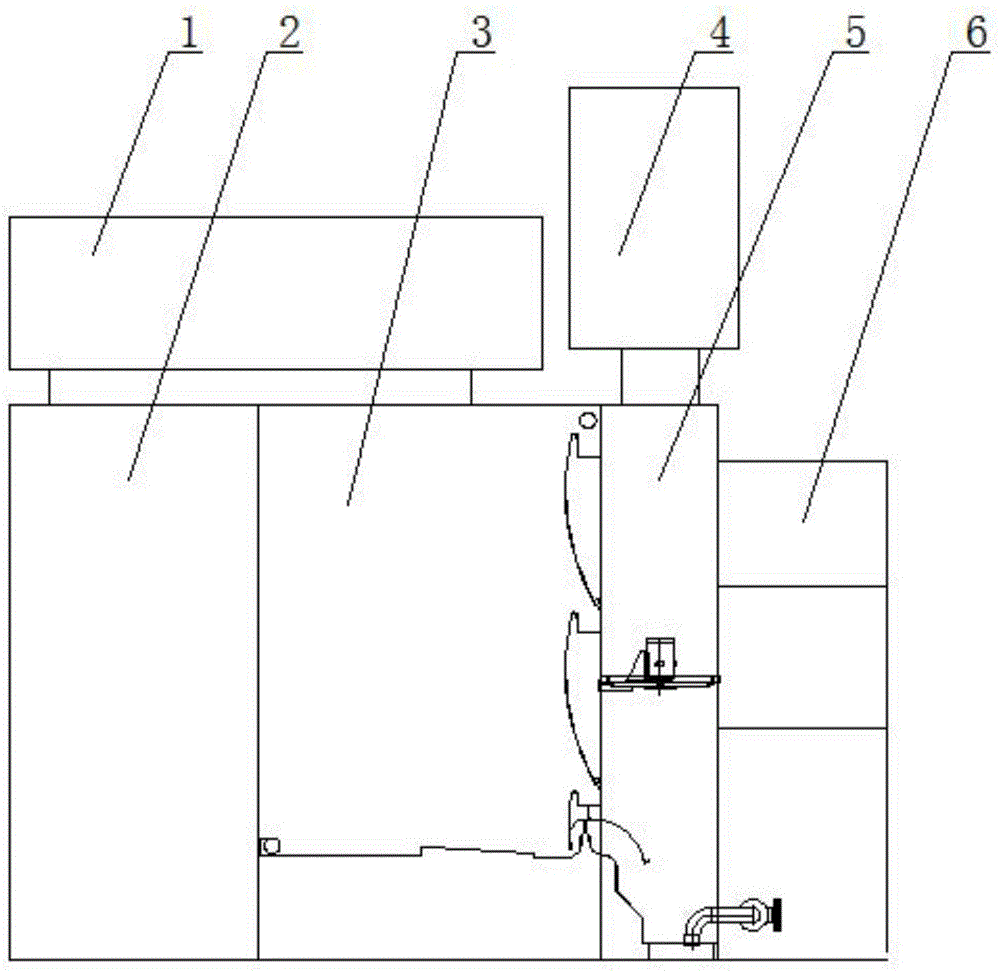

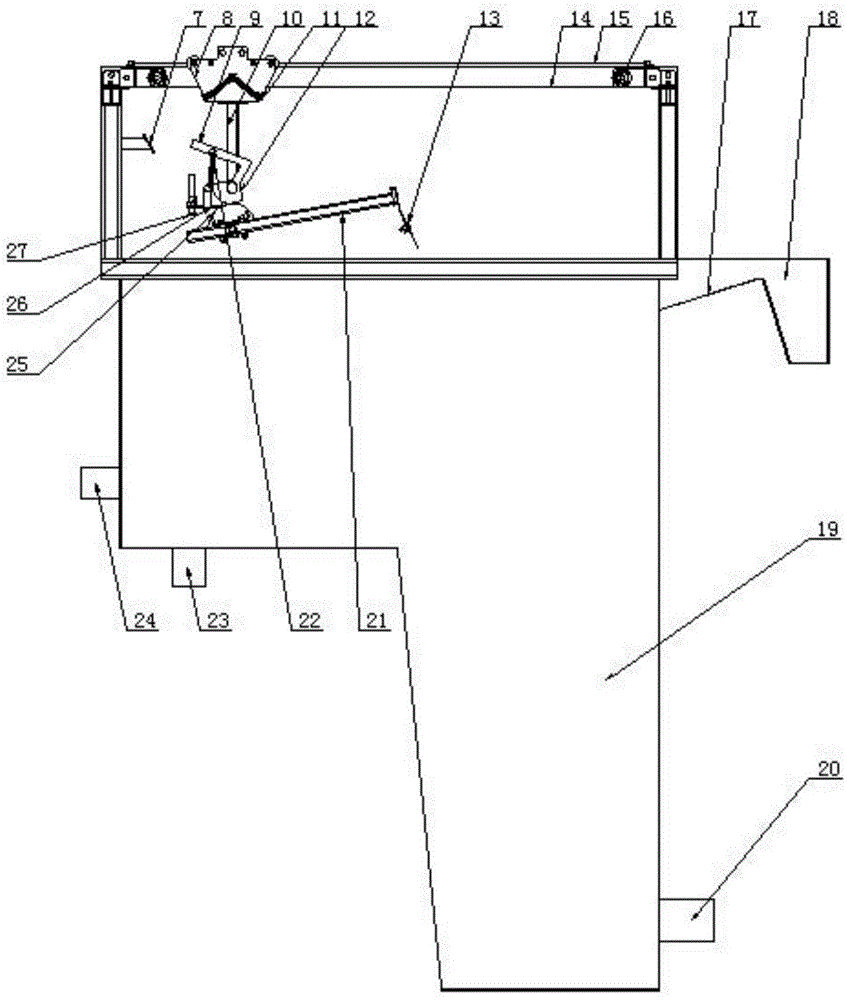

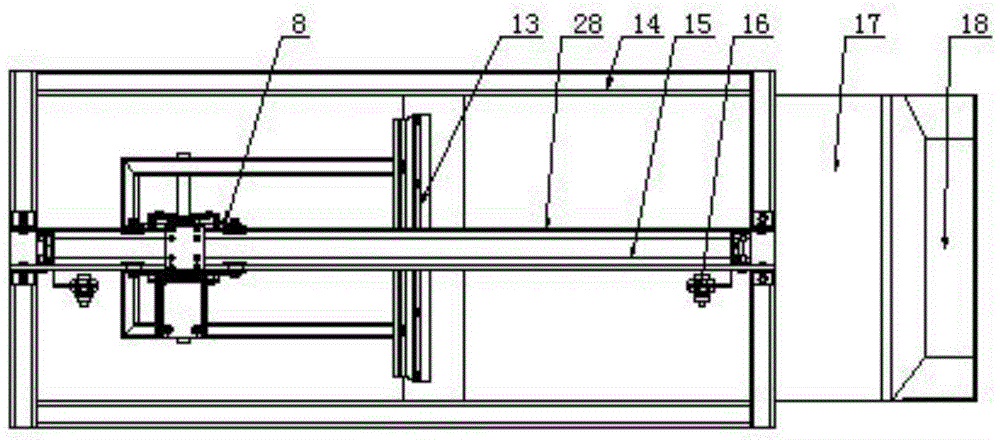

[0027] A paint spraying room with slag removal function, comprising a personnel operation room 2 and a paint spraying room 3 connected in sequence, a steam-water separation chamber 5 is connected behind the paint spraying room, a slag removal room 6 is connected behind the steam-water separation room, and the personnel operation room And the air blower 1 is installed above the spray booth, and the induced draft fan 4 is installed above the steam-water separation chamber. The box is provided with a medicament inlet 23, a liquid to be treated inlet 24, and a treatment liquid outlet 20. The frame is fixed on the liquid storage tank, the cylinder is a rodless cylinder, the guide rail and the cylinder are installed on the frame, electromagnetic i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com