Efficient feed batching device

A feed and high-efficiency technology, applied in the direction of feed, food science, application, etc., can solve the problems of limited processing range, poor degree of automation, and influence on production progress, so as to save electricity and time costs, achieve accurate proportioning, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

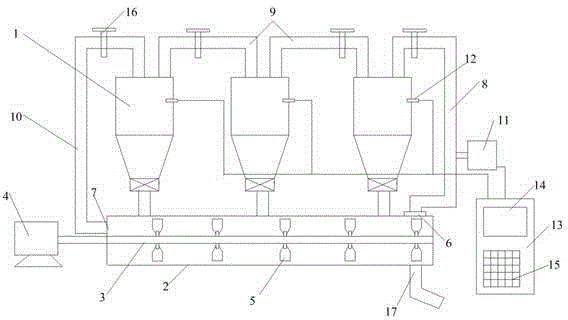

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a batching scale 1 and a mixer 2, characterized in that: the outlet of the batching scale 1 is connected to the mixer 2; a rotating shaft 3 is arranged in the middle of the mixing machine 2, and the rotating shaft 3 is connected to the stirring motor 4 connection; the rotating shaft 3 is connected with 3-5 sets of vertically symmetrical stirring paddles 5; the upper part of the mixing machine 2 is provided with a vent I6, and the other end is provided with a vent II7; the vent I6 and the pipeline I8 The other end of the pipeline I8 is connected to the upper air inlet of the batching scale 1; the air pump 11 is connected to the pipeline I8; the batching scale 1 is connected in series through the pipeline II9; the vent II9 is connected to the batching scale 1 through the pipeline III10 ; The material level sensor 12 is installed in the batching scale 1; The surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com