Rapeseed spiral stepping reseeding system

A rapeseed and step-by-step technology, applied in the directions of planter parts, etc., can solve the problems of increasing the complexity of structural components, high seed damage rate and high oil yield, and achieve the effects of simple structure, low cost and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

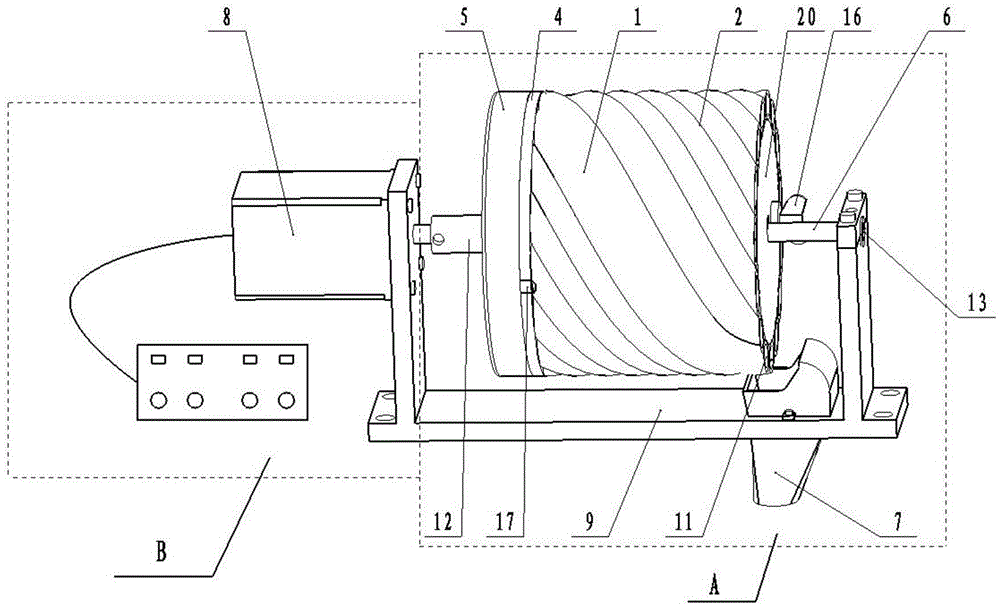

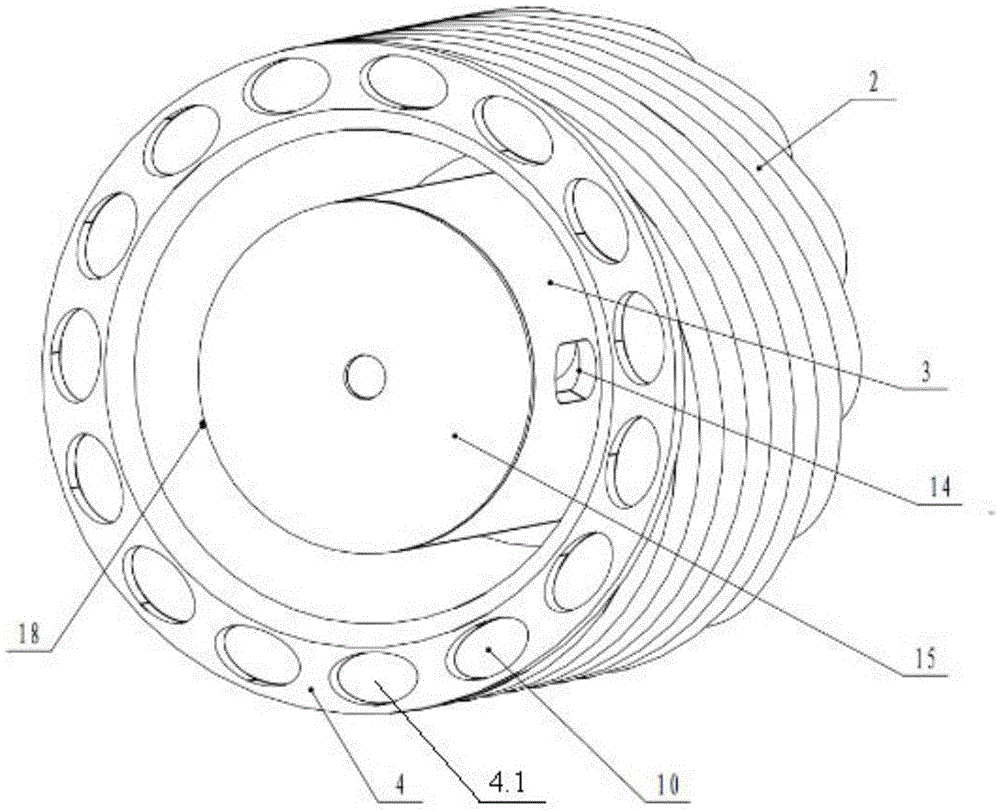

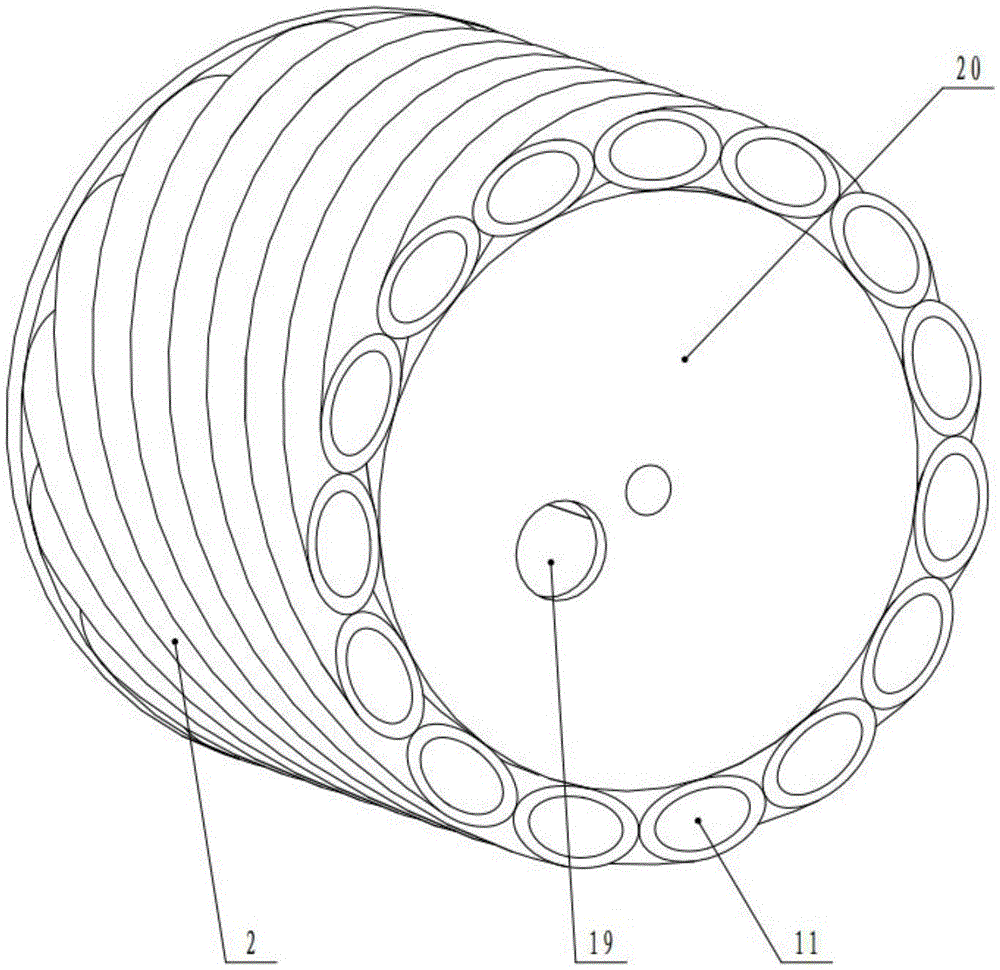

[0034] As shown in the figure, the rapeseed spiral stepping reseeding system includes a spiral reseeding device A and a stepping reseeding control module B.

[0035] As shown in the figure, the spiral tube type reseeding device A includes a seeding drum 1 and a bracket 9 provided with a seeding shaft 6. The seeding drum 1 is worn on the seeding shaft 6, and one end of the seeding shaft 6 passes through a coupling The device 12 is connected with the output shaft of the DC stepping motor 8, and the other end of the seeding shaft 6 is connected with a sliding bearing 13, and the sliding bearing 13 is fixedly installed on the support 9; the outer wall of the seeding cylinder 1 is provided with a plurality of spiral pipes 2, and the spiral The two ends of the pipeline 2 are respectively provided with a seed filling port 10 and a seed injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com