Automatic fault processing and safety control system and method for power information collection device

A technology for electricity collection and equipment failure, applied in the field of power system, can solve the problem of lack of strict guarantee of instructions, affecting the efficiency and accuracy of automatic remote processing, and achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

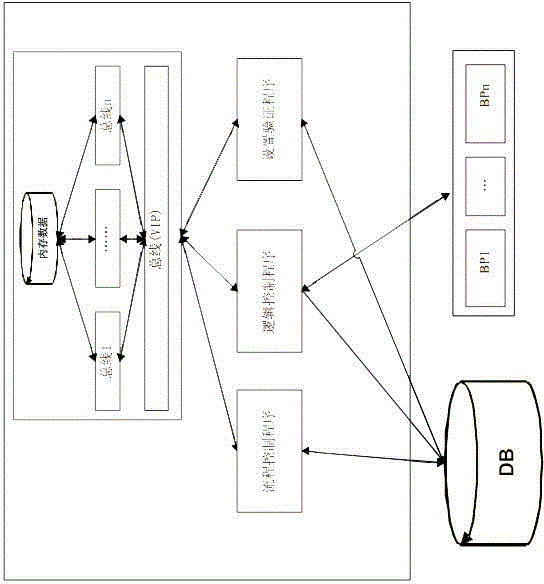

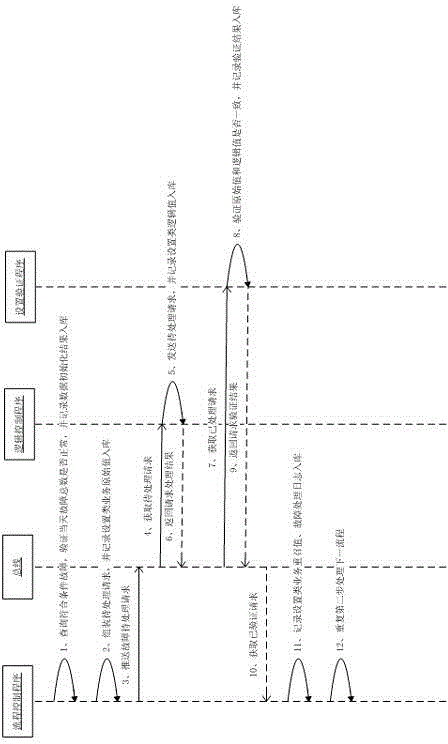

[0027] Example: such as Figure 4 As shown, the fault automatic processing and safety control system of electricity collection equipment includes on-site electric energy meters, on-site terminals and a master station connected to the on-site terminals through GPRS. The master station includes an automatic remote processing module and a safety control module. Faulty devices that can communicate normally can be automatically remote processed under safe and reliable conditions. The safety control module is responsible for process control, logic control and verification of remote processing instructions to ensure safety.

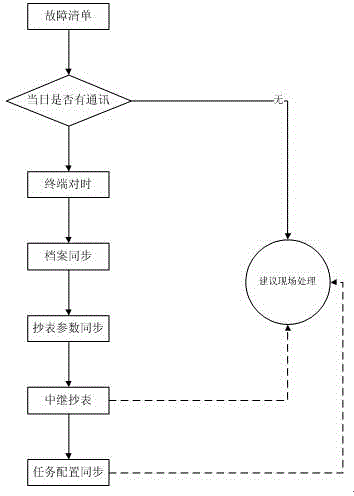

[0028] Such as figure 1 As shown, the automatic processing method for faulty equipment in electricity collection is to process the faulty equipment that can communicate normally on that day, step by step according to the steps of terminal time synchronization, file synchronization, meter reading parameter synchronization, relay meter reading, and task configurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com