An Intelligent Flaw Detection Method for Roller Rail Based on Mechatronics, Optical and Liquid Integration

A roller-type, light-liquid technology, applied in the direction of optical testing flaws/defects, can solve the problems of efficient and continuous detection of rails, damage, etc., and achieve the effect of improving stoppage operation methods, high measurement accuracy, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

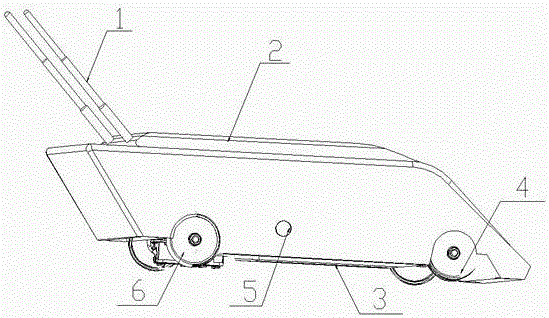

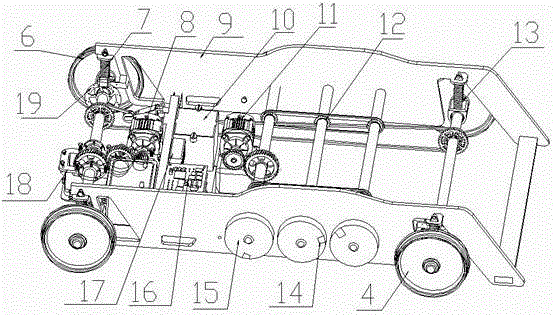

[0017] Embodiment 1. A method for intelligent flaw detection of roller-type rails based on electromechanical-optical-liquid integration,

[0018] It consists of front and rear wheels, frame, motor, gearbox, sensor, probe, brake disc, hydraulic pump, and power supply; among them: two rear wheels 6 and a gearbox 18 are installed on the rear axle, and the top end of the gearbox is The cover is connected to the upper end cover through top bolts, there are two pairs of gears in the gearbox, two-stage speed change, the motor Ι8 is suspended on the beam through the motor hanger on the frame, the power supply 10 is fixed on the bottom plate of the frame by bolts, and the rear shock absorber 7 is connected with the rear axle through the lower end, and the upper end is connected with the vehicle frame.

Embodiment 2

[0019] Embodiment 2. A roller-type rail intelligent flaw detection method based on electromechanical-optical-liquid integration, wherein: the gravity sensor 5 is installed on the shell 2 of the flaw detection vehicle to check whether the flaw detection vehicle runs smoothly, and the front wheels 4 and front shock absorbers 13 form the guiding system by the front axle.

Embodiment 3

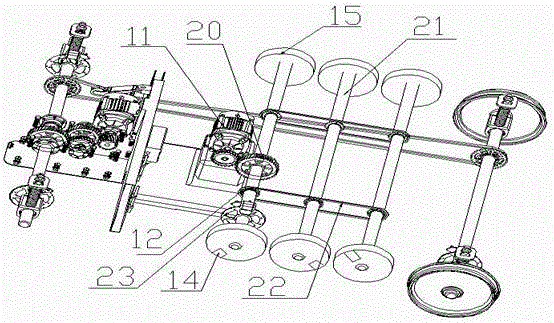

[0020] Embodiment 3. A roller-type rail intelligent flaw detection method based on electromechanical-optical-liquid integration, wherein: the flaw detection equipment is composed of a roller 15, a roller 21 and a probe 14, and three rollers are installed on both sides of the flaw detection vehicle, each A probe is installed on the roller, and the difference between the probes on the adjacent rollers is 120 degrees, and the speed of the roller relative to the flaw detection vehicle can be used to obtain higher detection speed and efficiency. The flaw detection probe on the roller will emit laser light to the rail at a certain speed to detect the damage inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com