Positive-pressure ventilation system used for seaborne booster station

An offshore booster station and positive pressure ventilation technology, which is applied in air-conditioning systems, space heating and ventilation, space heating and ventilation details, etc., can solve the problem that the operating life of the equipment is only a few years or even a few months, and the operating environment requirements are relatively high. High, equipment corrosion and other issues, to achieve normal heat dissipation, reduce ventilation resistance, reduce the effect of filtering wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

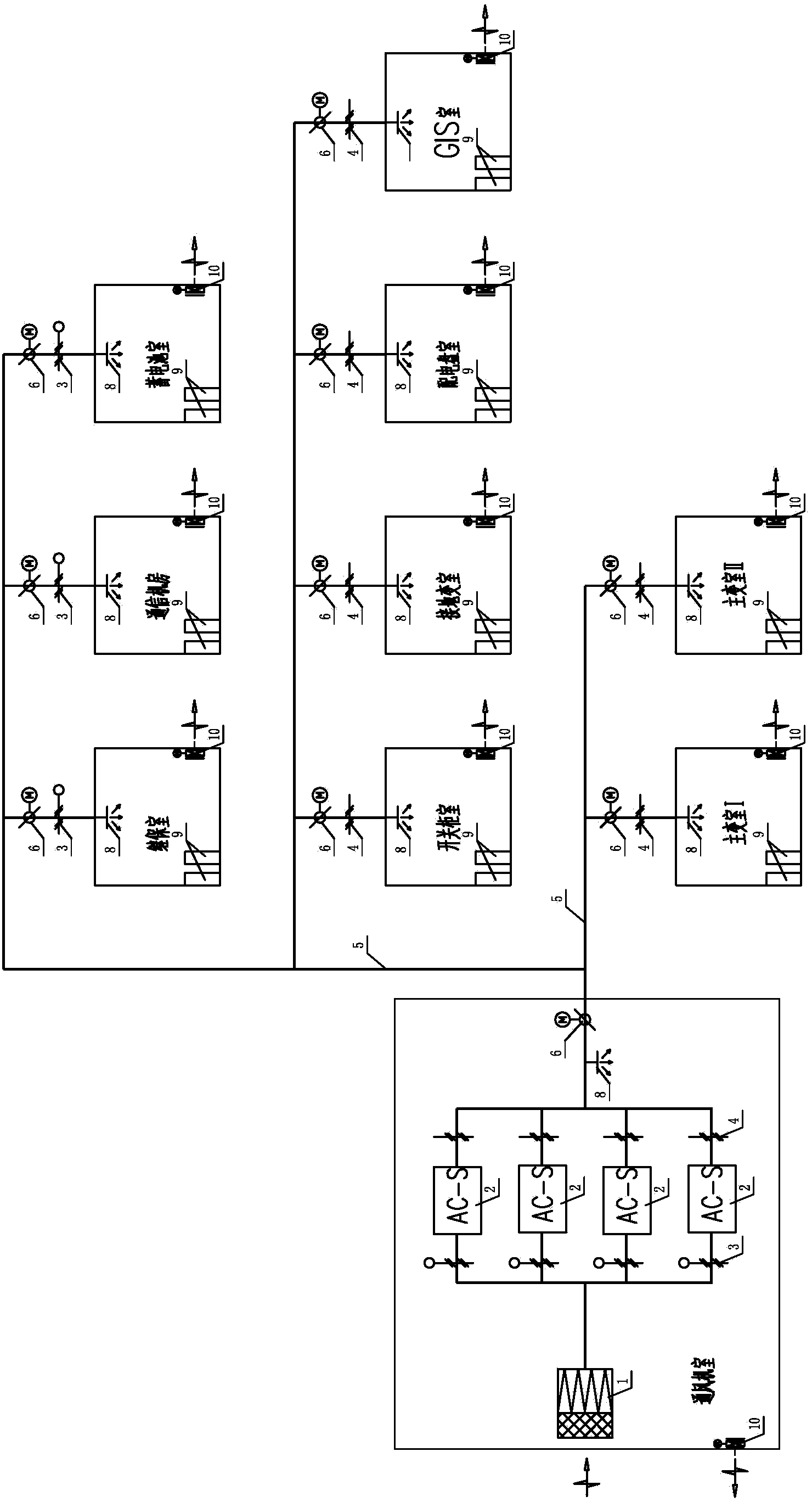

[0015] Such as figure 1 As shown, this embodiment is a 300MW offshore step-up substation, with two 150MW main transformers and corresponding switch cabinets, grounding transformers, switchboards, GIS, relay room, communication equipment, storage batteries and other equipment, each equipment Separately installed in the corresponding equipment room. In this embodiment, a set of positive pressure ventilation system is also set up to keep the equipment room at a positive pressure of 30-50 Pa. Due to the existence of continuous positive pressure, it is difficult for external corrosive air to enter the room, so that the indoor equipment is always in a low-corrosion environment. Avoid equipment corrosion and ensure normal operation of equipment.

[0016] The positive pressure ventilation system of this embodiment is composed of a salt mist removal system, a ventilation pipeline system, a room pressure relief device, a room air conditioning system and a monitoring system. The desalt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com