A method for installing a refrigerant pipe using a heat-insulating hanger device

A technology of refrigerant pipes and hangers, which is applied in the field of installing refrigerant pipes with heat-insulating hanger devices, can solve the problems of high material cost, low installation efficiency, and many heat-insulation gaps, etc., so as to reduce heat-insulation joints, prevent cold bridges, and simplify effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

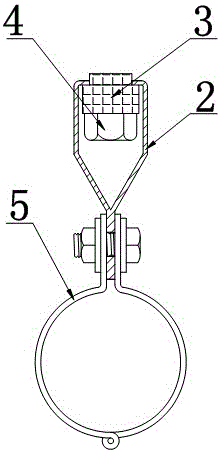

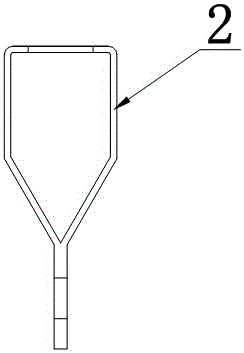

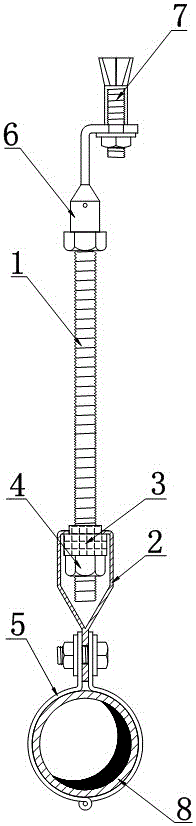

[0035] like figure 1 , 2 As shown, the present invention is mainly applied to the installation of refrigerant pipes, which includes an elevation adjustment hanging frame 2, a heat insulating ring 3, a nut 4 and a pipe holding mechanism. like figure 2 As shown, in the said elevation adjustment suspension frame 2, the top is provided with installation holes, while the bottom is provided with tube clip suspension holes. The pipe holding mechanism includes two pipe holding pieces 5 whose bottoms are hinged, the first threaded hole is set on one of the pipe holding pieces, and the second threaded hole is set on the other pipe holding piece. On the piece, the first threaded hole and the second threaded hole are the same size and shape as the pipe clamp lifting hole. By aligning the three and then using bolts, the elevation adjustment hanging frame 2 can be connected with the pipe clamping mechanism.

[0036] The heat insulation ring 3 is used to completely separate the elevation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com