Ring spinning yarn guide rubber roller with dynamic stereoscopic gathering smoothing function

A ring spinning, three-dimensional technology, applied in the field of textile processing, can solve the problems of easy blockage of the negative pressure accumulation mesh ring, high maintenance cost, and improvement of yarn quality, and achieve easy large-scale promotion and use, simple and reasonable structure, The effect of improving yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

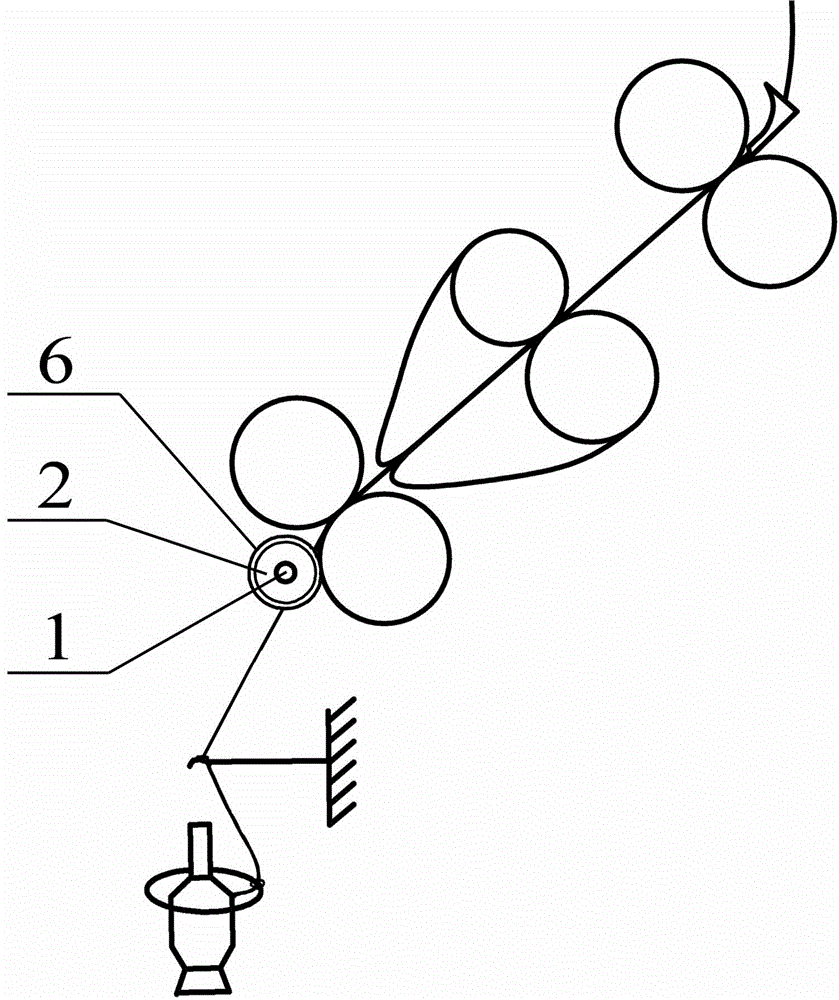

[0014]A ring spinning delivery cot with dynamic three-dimensional accumulation and smoothing function of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] see Attachment.

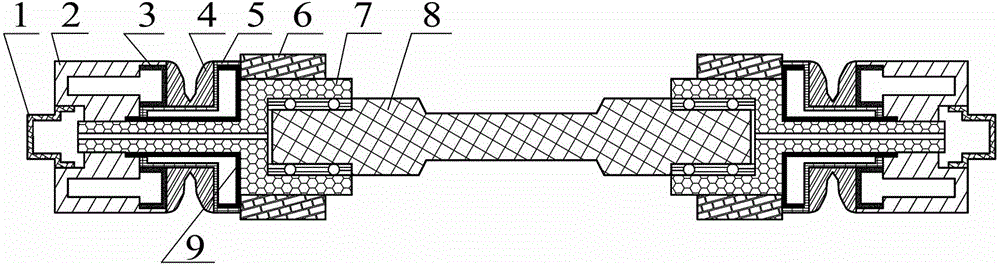

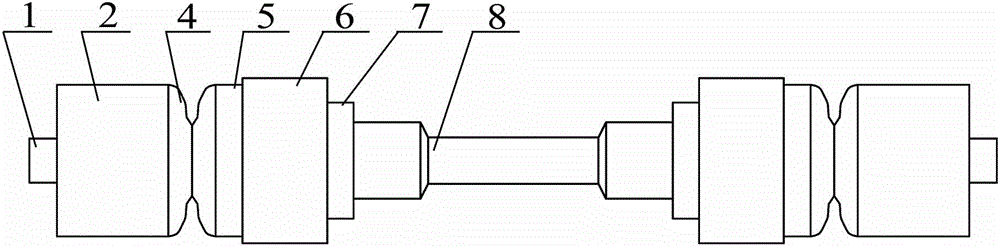

[0016] A yarn-leading rubber roller for ring spinning with dynamic three-dimensional accumulation and Fushun function, including a rubber sleeve 6 of the yarn-leading rubber roller and a fixed support shaft 8 installed in the rubber sleeve 6 through bearings, and on the rubber sleeve 6 The internal fixation is provided with a connection extension shaft 7, one end of the connection extension shaft 7 is sleeve-shaped, and one end of the sleeve shape is fixedly sleeved in the rubber sleeve 6, and the fixed support shaft 8 is fixed in the sleeve connected to the extension shaft 7 through a bearing. The other end of the extension shaft 7 is a hollow shaft, and one end of the hollow shaft extends outside the rubber sleeve 6. The end of the holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com