Full-automatic PCB labeling machine and implementation method thereof

A labeling machine, fully automatic technology, applied in the directions of labeling machines, labels, packaging, etc., can solve the problems affecting the overall production efficiency of the assembly line, low labeling and bar code efficiency, and unstable labeling quality, etc. Wide, improve production efficiency, save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

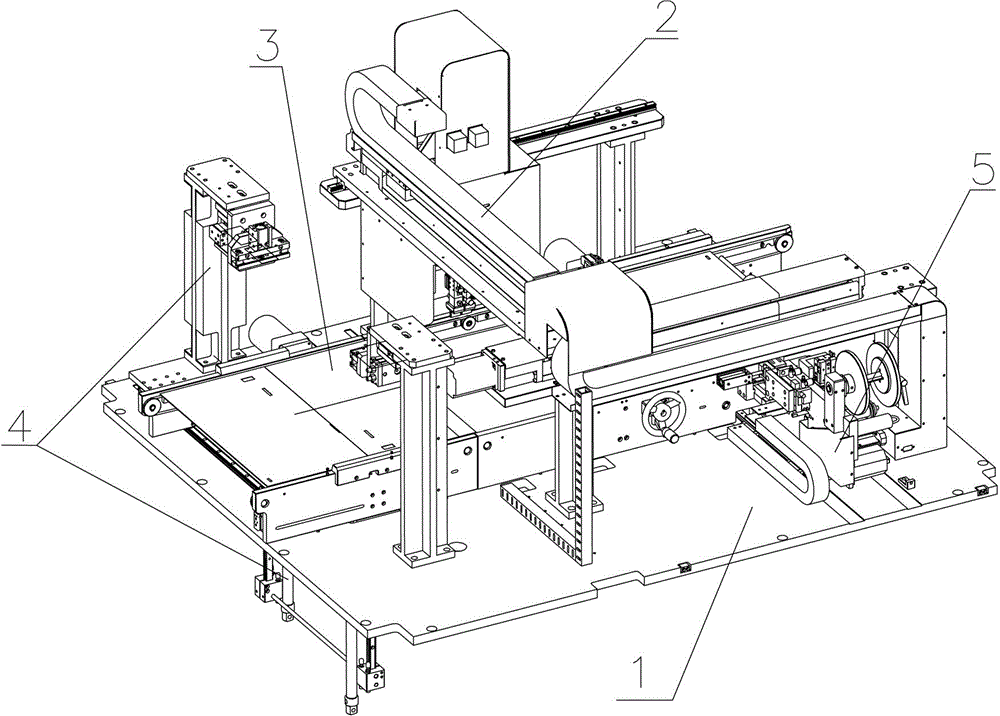

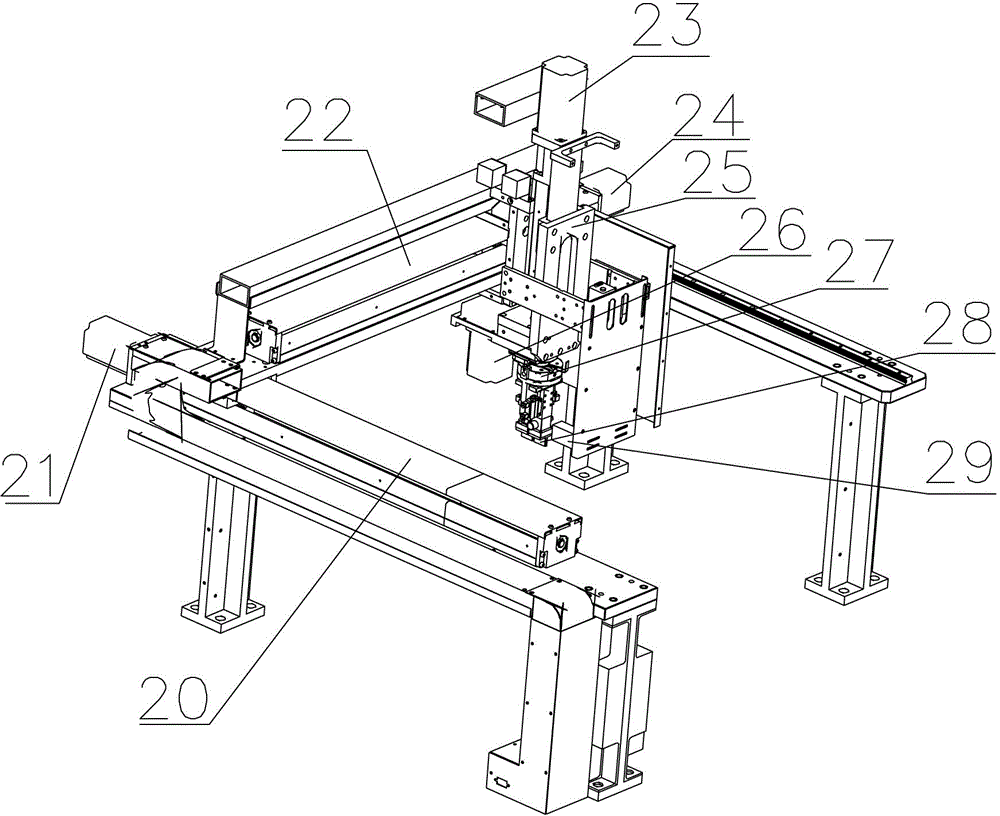

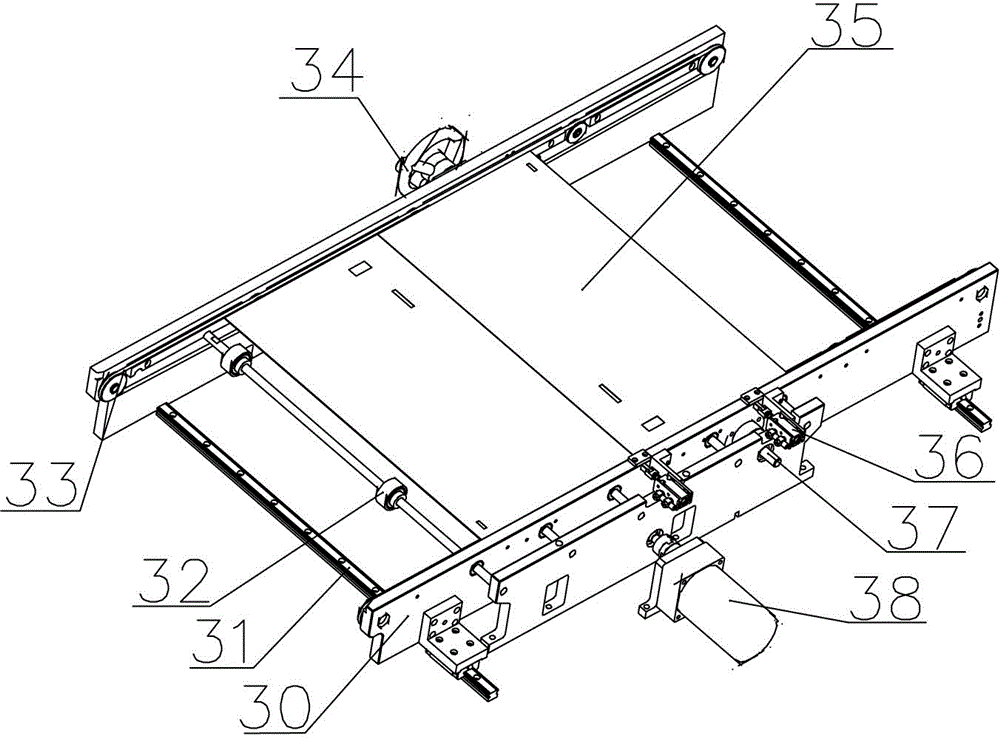

[0034] figure 1 It is a structural schematic diagram of the labeling machine of the present invention; it includes a frame 1, and a flow channel mechanism 3 for transporting PCB boards is arranged in the frame, and a flow channel mechanism 3 for supplying label material tape and peeling label material is arranged on the flow channel mechanism in the frame. The label feeding mechanism 5 to be labeled in the belt, the output end of the label feeding mechanism on the flow channel mechanism is also provided with a labeling manipulator mechanism 2 for transferring and sticking the label to the corresponding position of the PCB board. The labeling manipulator mechanism includes fixed supports for supporting the labeling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com