Buoyant box type overwater exploration operation platform

A working platform and floating box technology, applied in the direction of floating buildings, etc., can solve the problems of single structure and function, difficult angle adjustment, restricting the efficiency of pouring and exploration, and achieve long service life, improve equipment utilization, and solve chain breakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

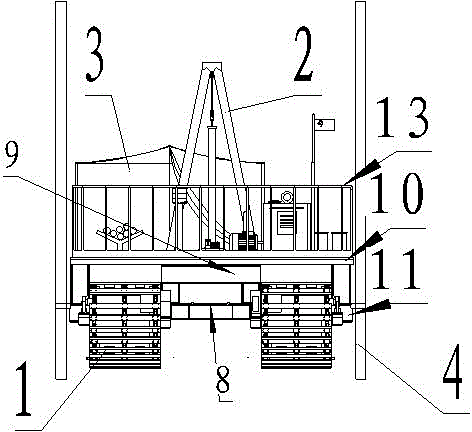

[0010] Refer to attached figure 1 , 2 , 3. The present embodiment mainly includes two pontoon tanks 1, a beam bracket 8 is arranged at the center of the opposite surfaces of the two pontoon tanks 1, a rotating platform 9 is arranged on the beam bracket 8, and the top surface of the rotating platform 9 is connected to the working platform 10 , the opposite side of the work platform 10 is connected to two positioning piles 4 through a hydraulic rod 11, the work platform 10 is provided with an exploration drilling rig hole 12 at the middle position corresponding to the two pontoons 1, and the top surface of the work platform 10 is provided with a console 7, and each positioning pile 4 is independently controlled by the console 7; a guardrail 13 is set around the work platform; a rest room 3 is set on the work platform.

[0011] According to the needs of actual digging and exploring, required equipment such as pouring probe rod supports can be set on the work platform 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com