Auxiliary spring bracket

A support and secondary spring technology, applied in the direction of springs, leaf springs, springs/shock absorbers, etc., can solve problems such as poor impact resistance and wear resistance, thick and heavy functions, and singleness, so as to reduce casting stress and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

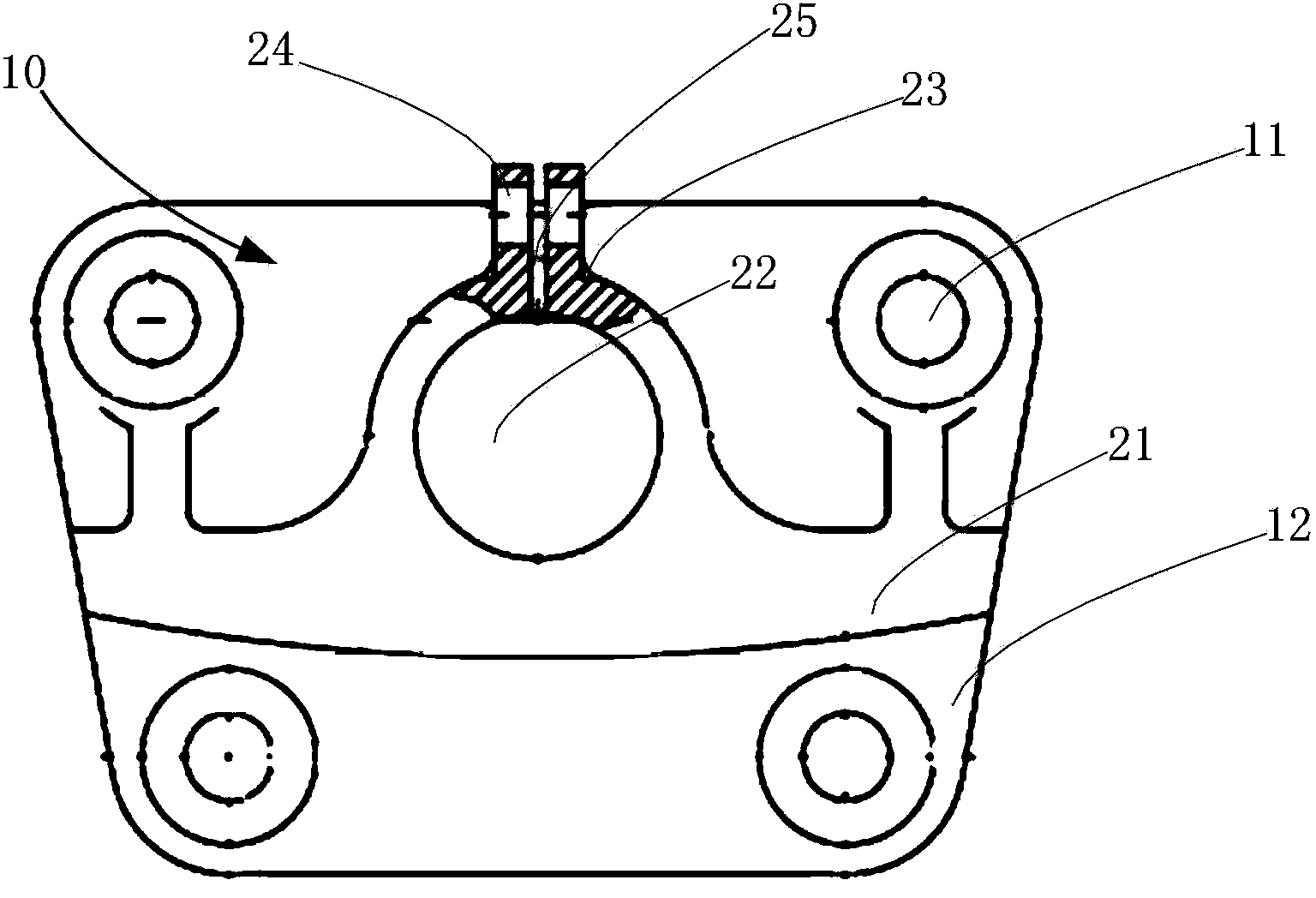

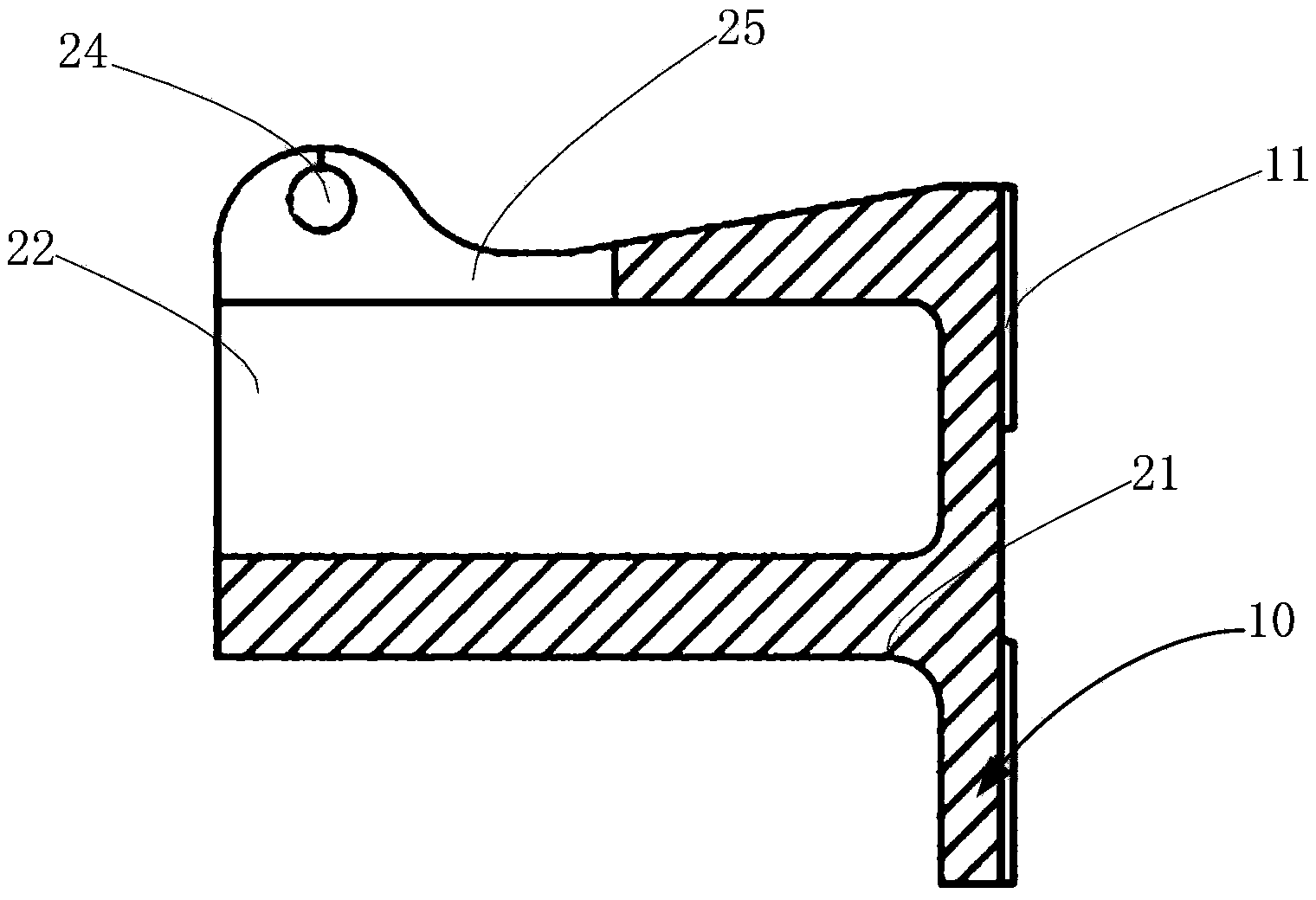

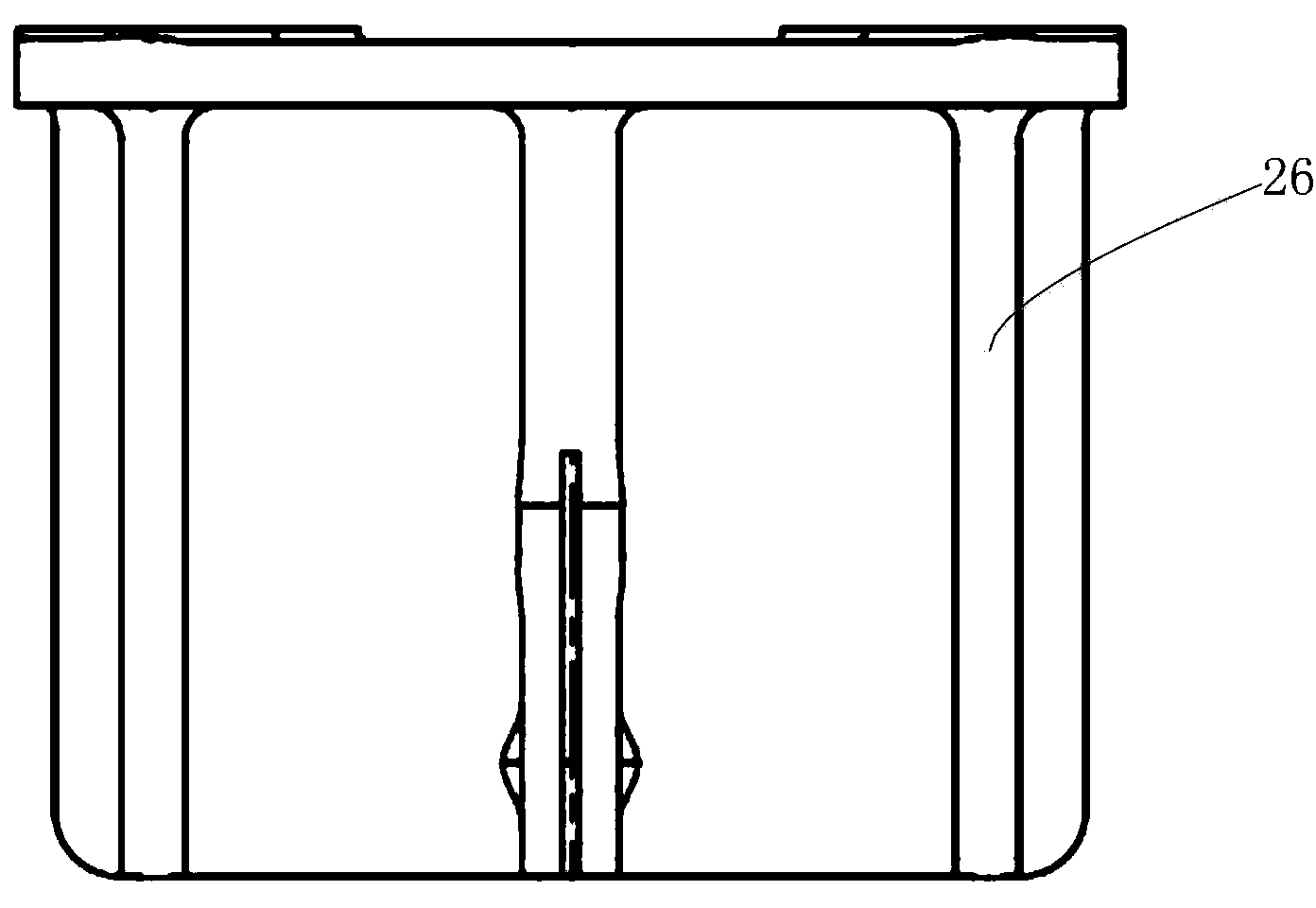

[0020] Such as Figure 1 to Figure 3 as shown, figure 1 It is a schematic diagram of the front view structure of an auxiliary spring support provided in Embodiment 1 of the present invention; figure 2 It is a schematic cross-sectional structure diagram of an auxiliary spring support provided in Embodiment 1 of the present invention; image 3 It is a schematic top view structure diagram of an auxiliary spring support provided in Embodiment 1 of the present invention.

[0021] An auxiliary spring support provided by the present invention includes a support mounting part 10 and a leaf spring contact part, the leaf spring contact part extends vertically to the side end surface of the support mounting part 10, the side end surface of the support mounting part 10 is trapezoidal and supports The seat mounting part 10 is detachably connected to the vehicle frame. The leaf spring contact part includes a secondary leaf spring connecting part 21 and a fender steel rod connecting part....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com