Automobile spare tire cover plate binding device

A technology for automobile spare tire cover plate and hemming device, which is applied in lamination device, transportation and packaging, vehicle parts, etc. It can solve the problems of large influence on workpiece positioning accuracy, inability to guarantee product consistency, and low degree of automation. Achieve the effects of eliminating the influence of human factors, ensuring product consistency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

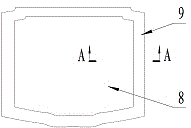

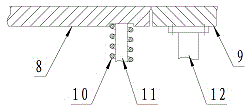

[0032] see figure 1 , the present invention mainly comprises lower mold turntable 1, lower tire mold 2, glue spraying device 3, hemming upper mold 4, fabric cutting upper mold 7 and upper mold mounting frame 6.

[0033] The whole hemming device is equipped with three stations: fabric punching station a, fabric glue spraying station b and compound hemming station c. The radii of the lower mold turntables corresponding to the three stations form an angle of 120 degrees. Fabric cutting upper die 7, glue spraying device 3 and hemming upper die 4 are respectively installed on these three stations and run simultaneously. During the production process, the positions of the fabric cutting uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com