Flux for narrow-gap submerged arc welding

A narrow gap and welding buried technology, applied in arc welding equipment, welding medium, welding equipment and other directions, can solve the problems of good effect and low cost, and achieve the effect of good welding quality, high production efficiency and low comprehensive cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

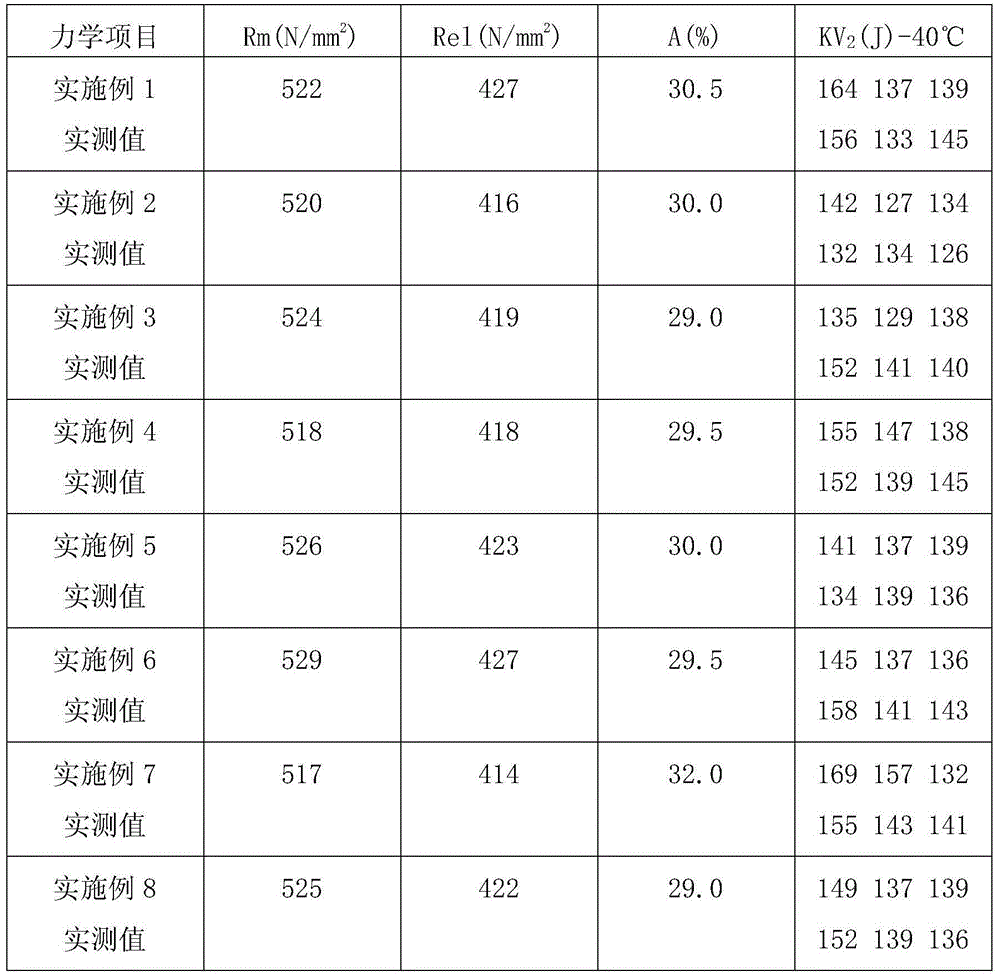

Examples

Embodiment 1

[0020] Embodiment 1 Each portion is calculated according to 10kg

[0021] Example 1:

[0022] A submerged arc flux for narrow gap welding, the sintered flux components are composed of calcined α-type aluminum oxide, fluorite, coarse magnesia, fine magnesia, silica mud, wollastonite, barium fluoride, metal manganese and ferrosilicon Composition, the parts by weight of the formula components are: 10 parts of calcined α-type aluminum oxide, 20 parts of fluorite, 15 parts of coarse magnesia, 15 parts of fine magnesia, 15 parts of bauxite, 15 parts of wollastonite , 1 part of rutile, 8 parts of manganese metal, and 1 part of ferrosilicon.

Embodiment 2

[0024] A submerged arc flux for narrow gap welding, the sintered flux components are composed of calcined α-type aluminum oxide, fluorite, coarse magnesia, fine magnesia, silica mud, wollastonite, barium fluoride, metal manganese and ferrosilicon Composition, the parts by weight of the formula components are: 13 parts of calcined α-type aluminum oxide, 24 parts of fluorite, 17 parts of coarse magnesia, 12 parts of fine magnesia, 10 parts of bauxite, 15 parts of wollastonite , 2 parts of rutile, 6 parts of manganese metal, and 1 part of ferrosilicon.

Embodiment 3

[0026] A submerged arc flux for narrow gap welding, the sintered flux components are composed of calcined α-type aluminum oxide, fluorite, coarse magnesia, fine magnesia, silica mud, wollastonite, barium fluoride, metal manganese and ferrosilicon Composition, the parts by weight of the formula components are: 15 parts of calcined α-type aluminum oxide, 28 parts of fluorite, 20 parts of coarse magnesia, 15 parts of fine magnesia, 10 parts of bauxite, 5 parts of wollastonite , 3 parts of rutile, 1 part of manganese metal, and 3 parts of ferrosilicon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com