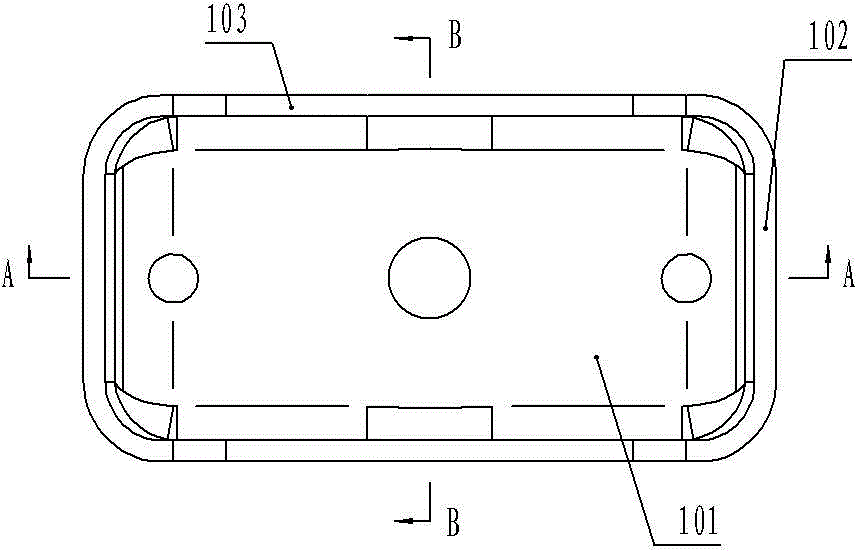

Spring seat plate forming die

A spring seat and plate pressing technology, which is applied in the field of stamping die manufacturing, can solve problems such as the difficulty of stripping the spring seat plate, and achieve the effects of smooth stripping, accurate positioning, and guaranteed processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

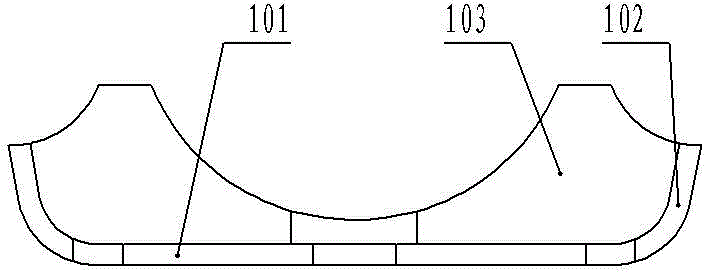

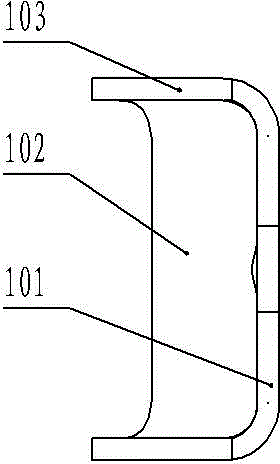

[0016] Such as Figure 4 , Figure 5 A kind of spring seat plate pressing die shown, comprises upper mold base 8 and lower mold base 7, and punch 14 and upper clamping plate 10 that is sleeved on the outside of punch 14 are equipped with on the bottom of upper die base 8, on punch 14 There are six limit holes, and each limit hole is equipped with a screw plug 11 and an ejector rod 13 protruding from the bottom of the punch 14, and a spring 12 is installed between the ejector rod 13 and the screw plug 11; the upper part of the lower die base 7 The lower template 16 and the concave template 15 inserted on the lower template 16 are equipped with six positioning blocks 9 with bolts near the concave template 15 of the lower template 7, and one end of the positioning block 9 is crimped on the concave template 15. 9 as Image 6 As shown; a lower backing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com