Intermittent coating electrode lug gluing device and gluing rack thereof

A gluing device and gluing machine technology, applied in the direction of the surface coating liquid device, spraying device, coating, etc., can solve the problem of affecting the accuracy of the coating operation, the blockage of the extrusion port of the extrusion head, and the inability to obtain product quality. Guarantee etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

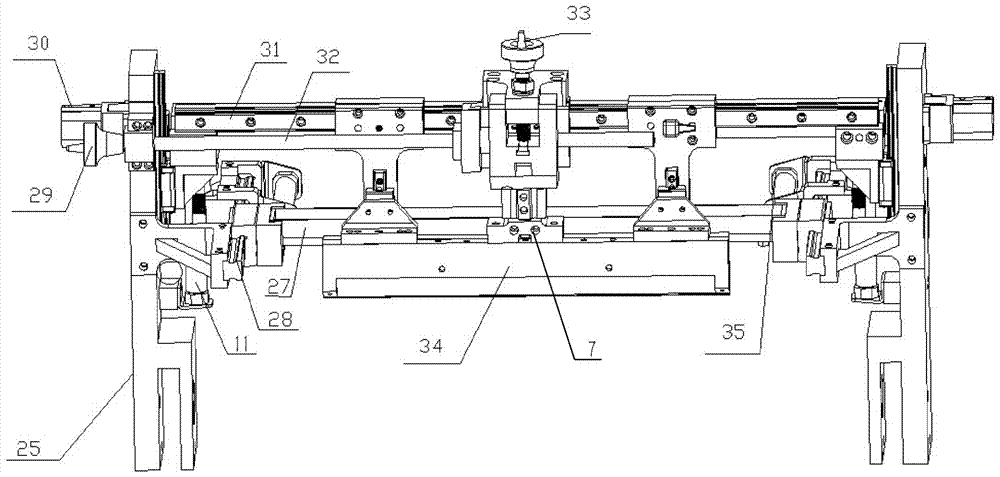

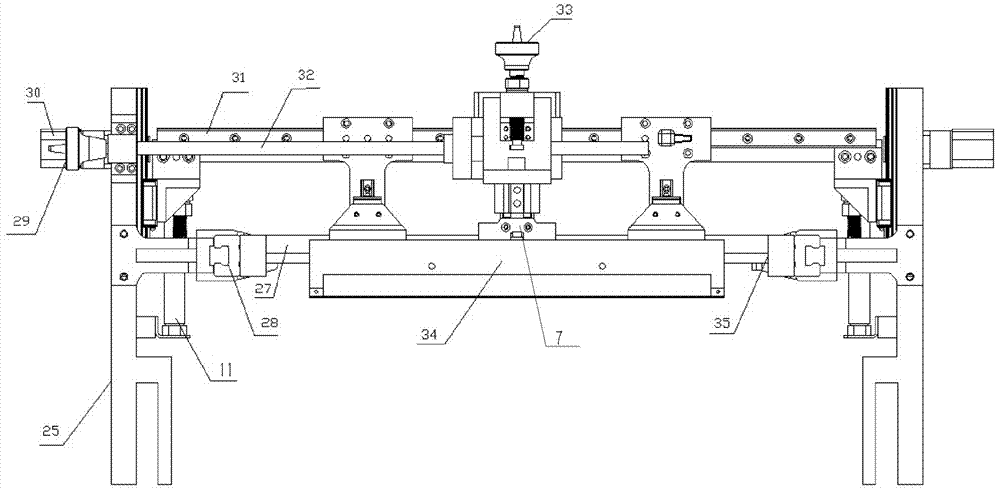

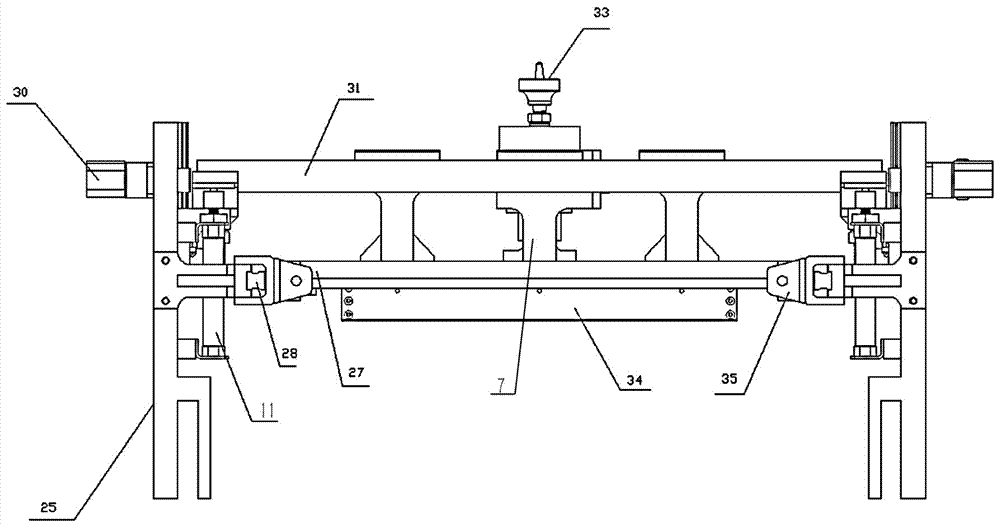

[0026] The embodiment of intermittent coating lug gluing device among the present invention: as Figure 1 to Figure 7 As shown, the gluing device is an automatic gluing device in the gluing system for intermittently coating the root of the lug. It is composed of a gluing frame and an actuator. A beam-type nozzle bracket 31 and a water tank bracket 27 are bridged between the two supports. The water tank bracket 27 is located below the nozzle bracket 31. A water tank 34 extending left and right is fixed on the front side of the water tank bracket 27. The nozzle bracket The front side of the frame 31 is equipped with a gluing nozzle 7 . The left and right ends of the nozzle bracket 31 are respectively guided and moved in the up and down direction by the lifting guide rail mechanism and assembled on the opposite sides of the two supports. On the opposite side of the seat, the lifting guide rail mechanism and the translation guide rail mechanism 28 are vertically staggered in spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com