Two-fluid atomization nozzle

An atomizing nozzle and two-fluid technology, which is applied in the direction of liquid injection devices, injection devices, etc., can solve the problem of reducing the service life of atomizing components, it is difficult to ensure the atomization rate and atomization degree of wastewater, and the atomizing components are easily corroded and damaged. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

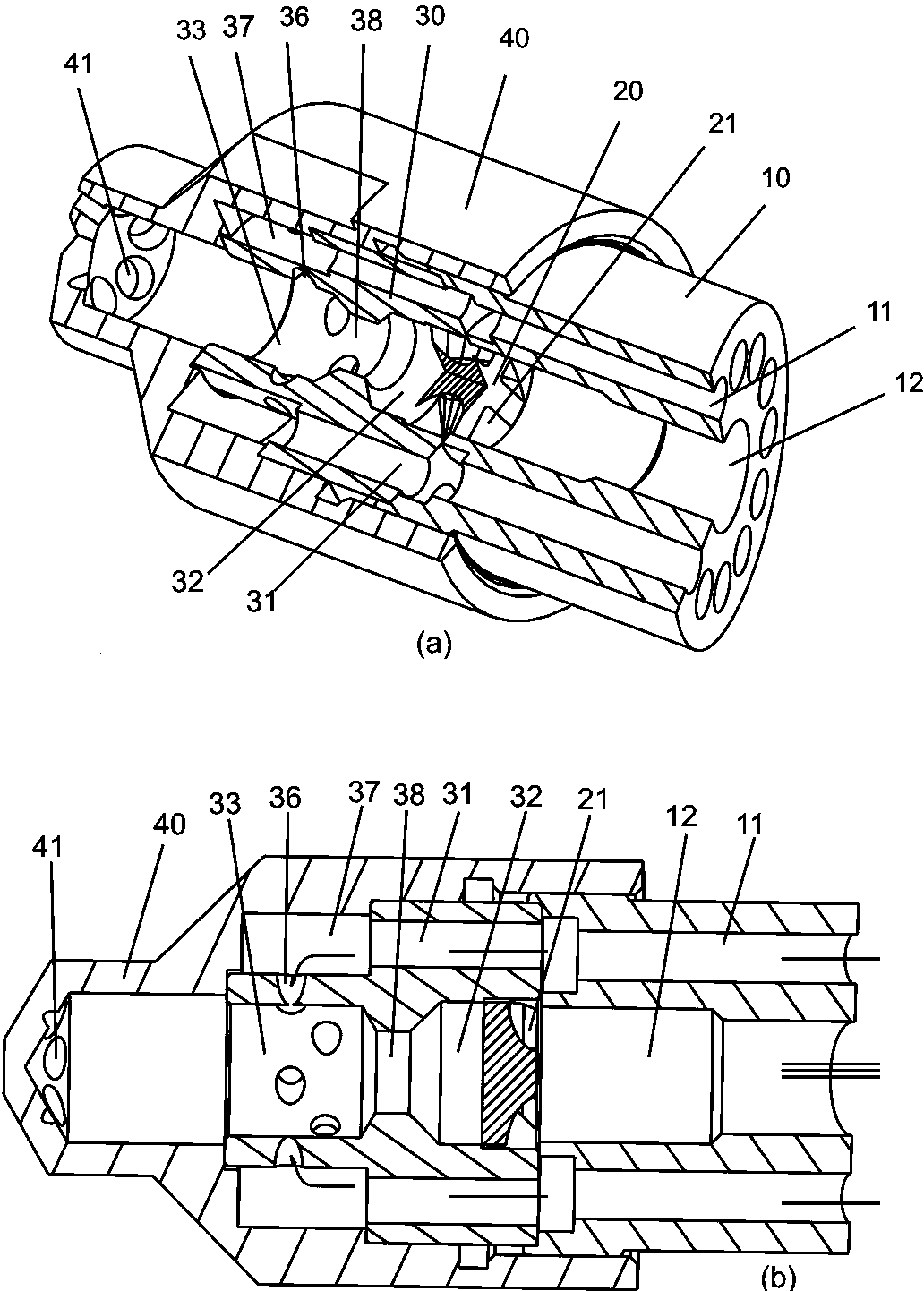

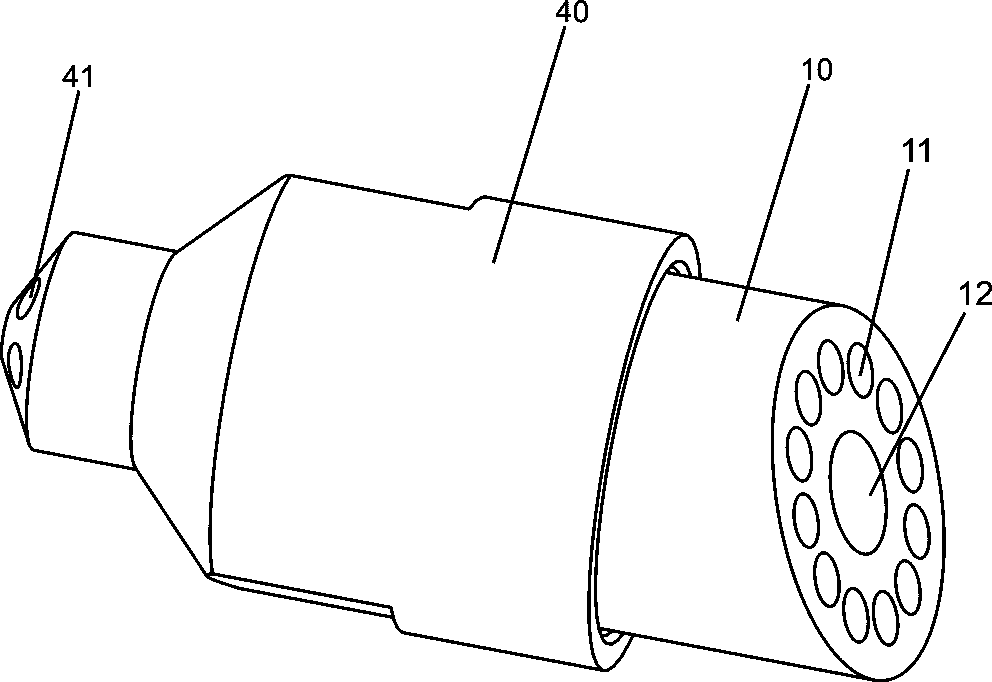

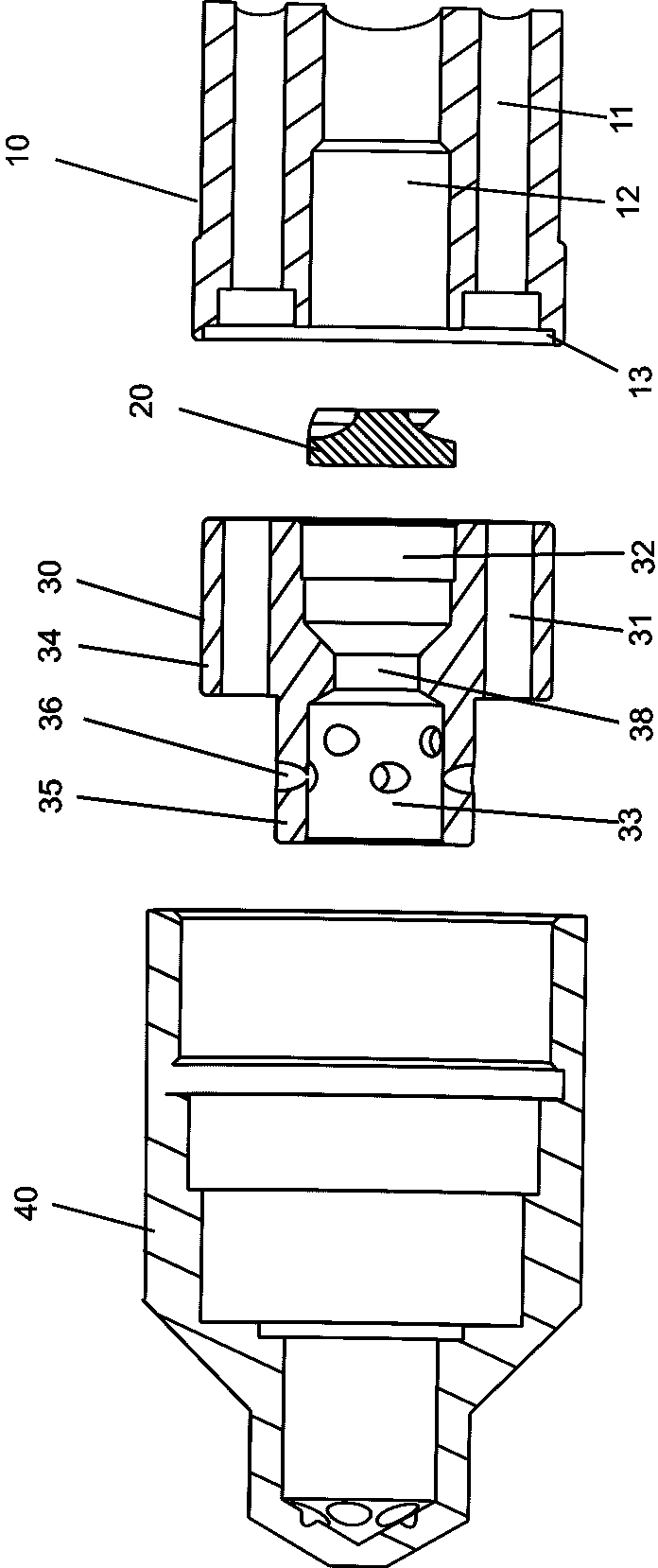

[0037] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the embodiment of the present invention. The two-fluid atomizing nozzle includes a fluid joint 10, a liquid swirl plate 20, a two-fluid mist nozzle, which are arranged in separate parts and are detachably assembled into one. The atomizing chamber 30 and the shower head 40, wherein, the shower head 40 is formed with a cavity, one end of the cavity is provided with an opening and the other end is provided with a spray hole 41; the two-fluid atomization chamber 30, the liquid swirl sheet 20 and the fluid joint 10 are sequentially assembled and arranged in the aforementioned cavity toward the opening direction; the inside of the dual-fluid atomization chamber 30 is formed with a first gas flow path 31 and a first liquid flow path 32, and the first gas flow path 31 An atomization cavity 33 is formed at the intersection with the first liquid flow channel 32, and the atomization cavity 33 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com