High pressure pumps for fuel injection systems

A high-pressure pump and housing technology, which is applied in the direction of pumps, multi-cylinder pumps, liquid variable capacity machines, etc., to achieve the effect of time consumption and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

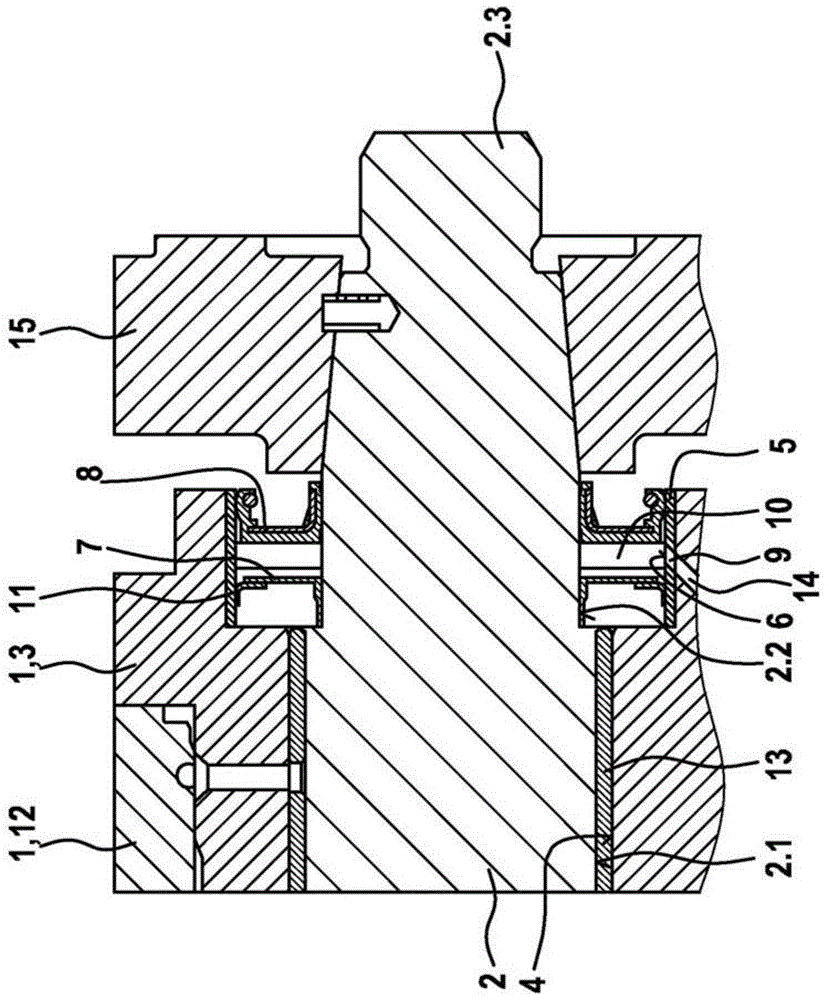

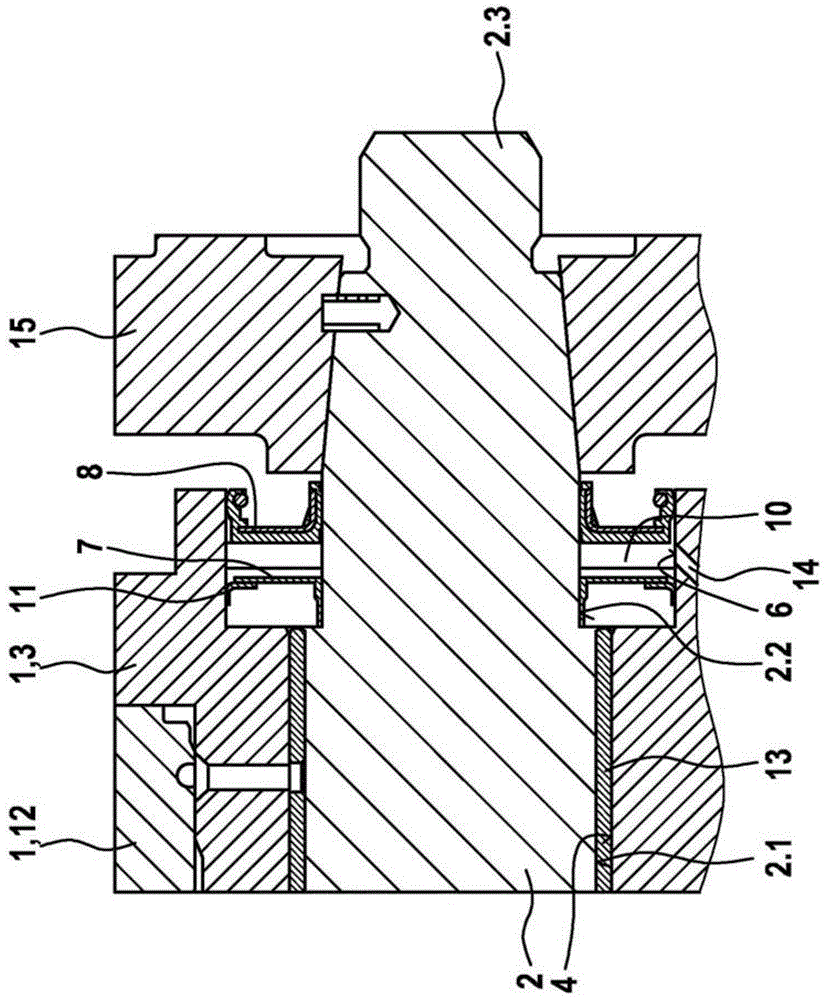

[0022] The high pressure pump of the present invention is figure 1 The preferred embodiment shown in includes a housing 1 with a base body 12 and a flange component 3 which is connected to the base body 12 . A bearing bore 4 designed as a stepped bore for receiving the shaft section 2 . 1 of the drive shaft 2 is formed in the flange component 3 . A plain bearing sleeve 13 for forming a plain bearing is inserted into the inner first section of the bearing bore 4 . The sleeve 5 for forming a running surface for the two shaft sealing rings 7 , 8 is pressed into the other outer section of the bearing bore 4 , which has a larger diameter than the first section. Inner diameter. The larger inner diameter forms a receiving space for the shaft sealing rings 7 , 8 .

[0023] The two shaft sealing rings 7 , 8 arranged at an axial distance relative to each other press against an outer peripheral region 2 . 2 of the shaft section 2 . of the outer diameter. The drive shaft 2 is therefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com