Electrochemical reduction device, and method for producing hydrogenated product of aromatic hydrocarbon compound or nitrogenated heterocyclic aromatic compound

A technology of aromatic compounds and aromatic compounds, applied in reduction electrolysis, electrolysis process, electrolysis components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

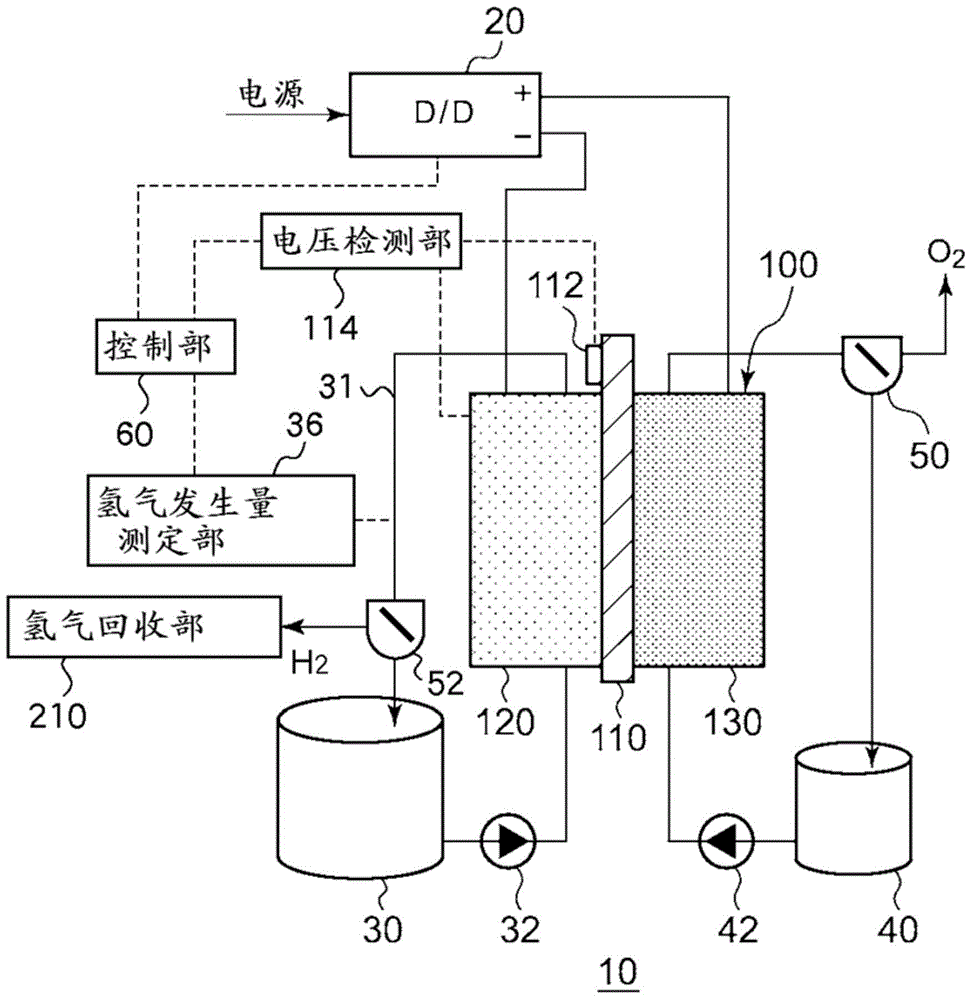

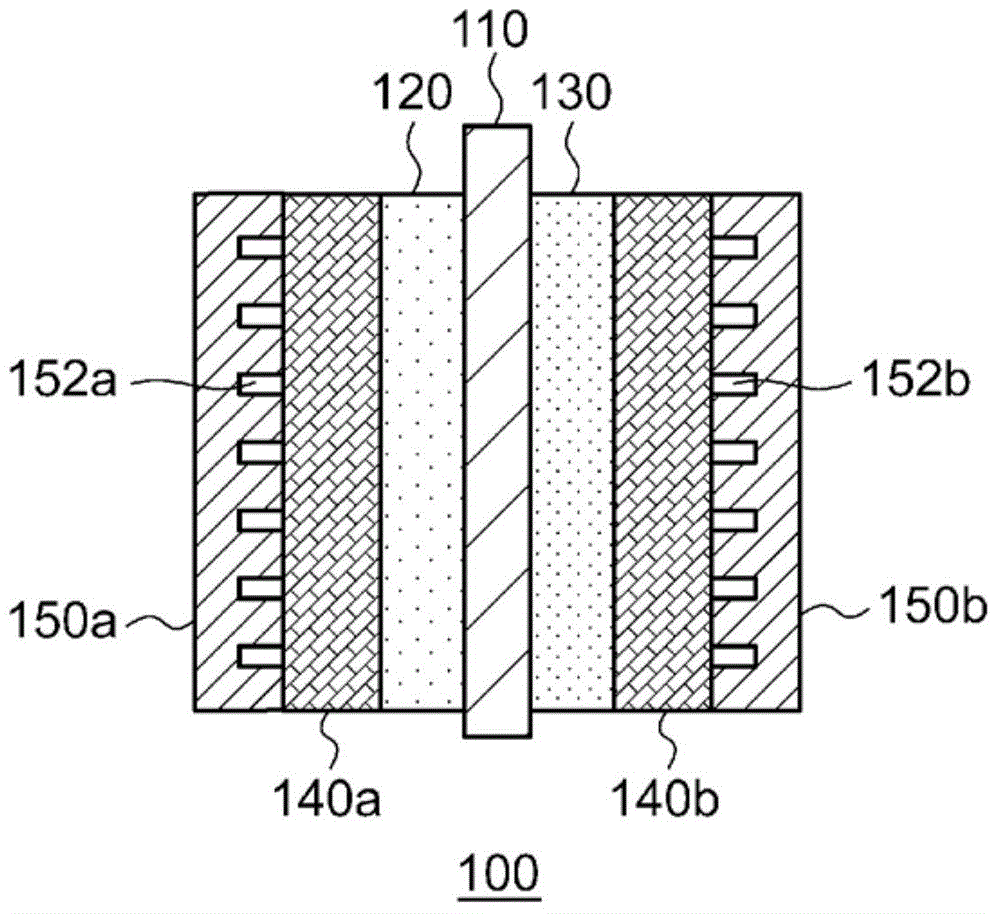

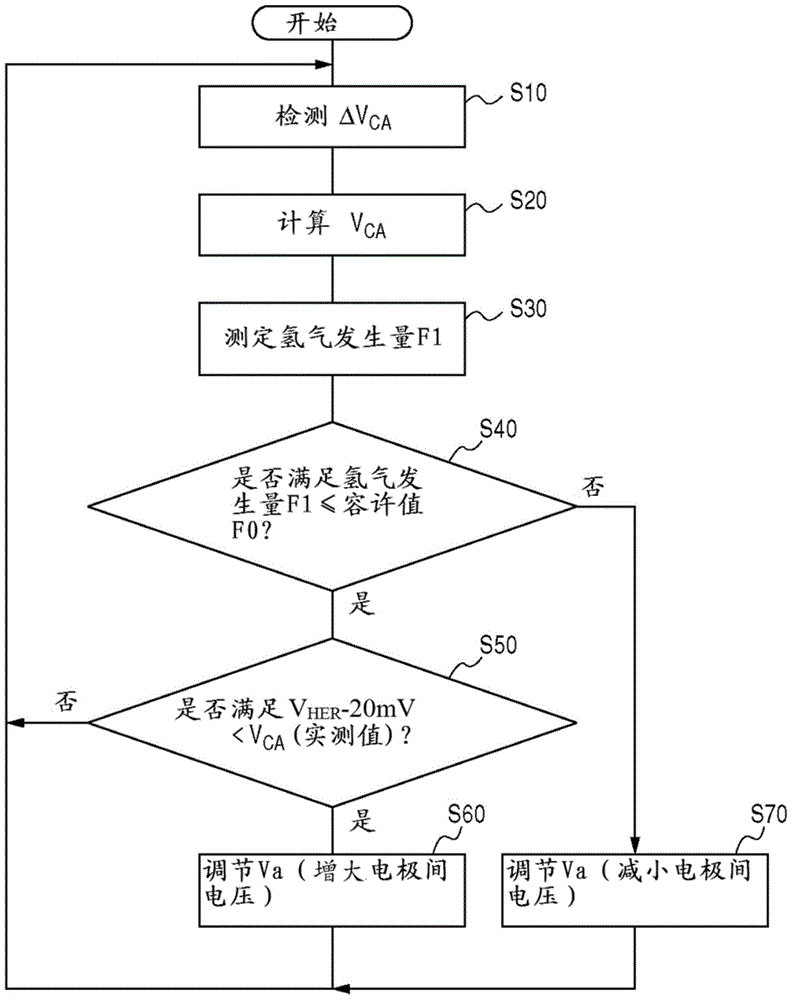

[0029] figure 1 It is a schematic diagram showing the schematic configuration of the electrochemical reduction device 10 according to the embodiment. figure 2 It is a diagram showing a schematic configuration of an electrode unit 100 included in the electrochemical reduction device 10 according to the embodiment. Such as figure 1 As shown, the electrochemical reduction device 10 includes an electrode unit 100, an electrical control unit 20, an organic matter storage tank 30, a hydrogen generation measurement unit 36, a water storage tank 40, a gas-water separation unit 50, a gas-liquid separation unit 52, and a control unit. 60 and the hydrogen recovery unit 210.

[0030] The electrical control unit 20 is, for example, a DC / DC converter that converts an output voltage of a power supply into a predetermined voltage. The positive output terminal of the electrical control unit 20 is connected to the positive electrode of the electrode unit 100 . The negative output terminal ...

Embodiment approach 2

[0080] Figure 4 It is a schematic diagram showing the schematic configuration of the electrochemical reduction device 10 according to the second embodiment. Such as Figure 4 As shown, the electrochemical reduction device 10 includes an electrode unit assembly 200, an electrical control unit 20, an organic matter storage tank 30, a hydrogen generation measurement unit 36, a water storage tank 40, a gas-water separation unit 50, a gas-liquid separation unit 52, The control unit 60 , the voltage detection unit 114 and the hydrogen recovery unit 210 . The electrode unit assembly 200 has a stacked structure in which a plurality of electrode units 100 are connected in series. In this embodiment, the number N of electrode units 100 is five, but the number of electrode units 100 is not limited thereto. It should be noted that the structure of each electrode unit 100 is the same as that of the first embodiment. exist Figure 5 In FIG. 2 , the electrode unit 100 is omitted from i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com