A propellant burning rate testing device under tension

A stretching device and stretching state technology, applied in the direction of chemical analysis using combustion, can solve the problems of affecting the ballistic performance of the engine, affecting the gas generation rate of the engine, and low tensile modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

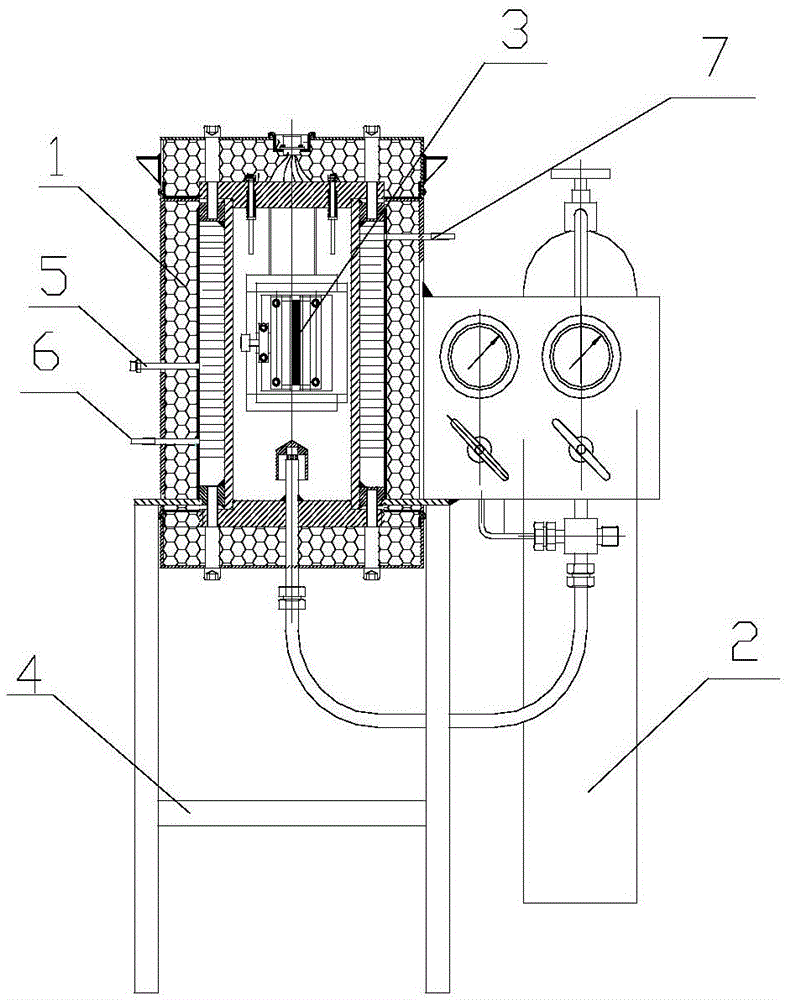

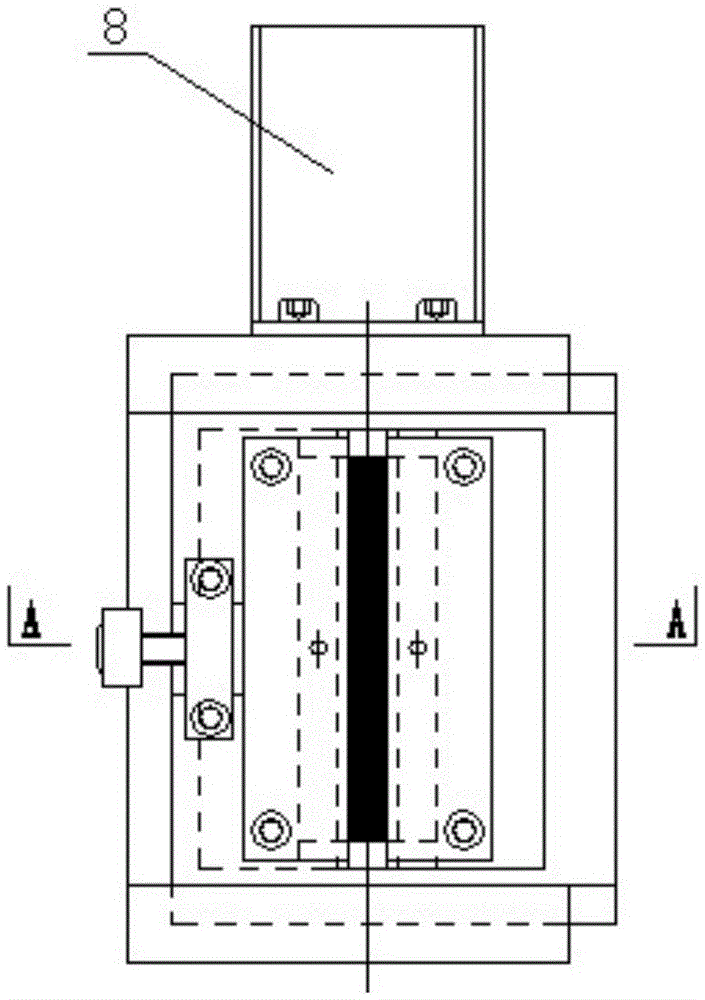

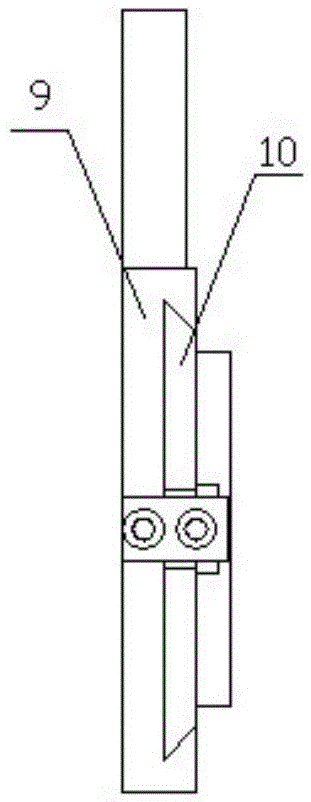

[0020] This embodiment is a test device for propellant burning rate in a stretched state.

[0021] refer to Figure 1 to Figure 7 , the propellant burning rate test device under the tension state of this embodiment is composed of a constant temperature and pressure box 1, a nitrogen cylinder 2, a stretching device 3, and a workbench 4; the constant temperature and pressure box 1 is fixed on the workbench 4, The nitrogen cylinder 2 is installed on one side of the workbench 4. The nitrogen cylinder 2 is connected with the constant temperature and pressure box 1 through a pipeline. A pressure gauge is installed on the nitrogen cylinder 2. When working, the high-pressure inert gas in the nitrogen cylinder 2 is transmitted to the constant temperature chamber. In the buffer device of the constant pressure box 1, it is ensured that the pressure in the constant temperature and constant pressure box 1 reaches the set pressure. Insulation material is filled between the inner and outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com