Test device and test method for testing kinetic shear characteristics between pipe piles and grouting soil bodies

A test device and test tube technology, which is applied in the direction of using a stable shear force to test the strength of materials, etc., can solve the problems of poor pertinence of test equipment and test methods, difficulty in determining the similarity ratio of test models, and low accuracy. Achieve the effect of avoiding boundary effects, reliable basic data, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not used to limit the present invention.

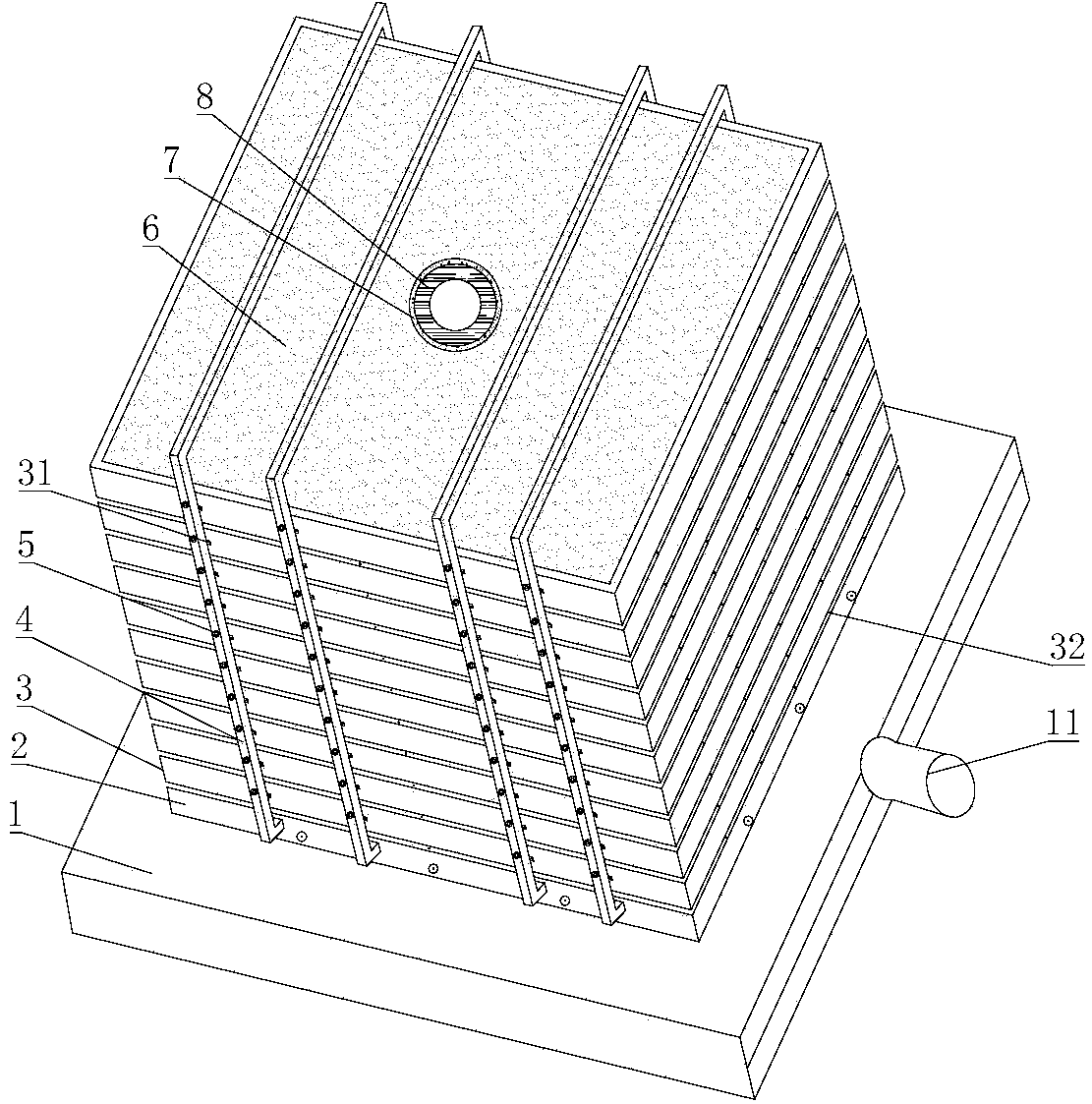

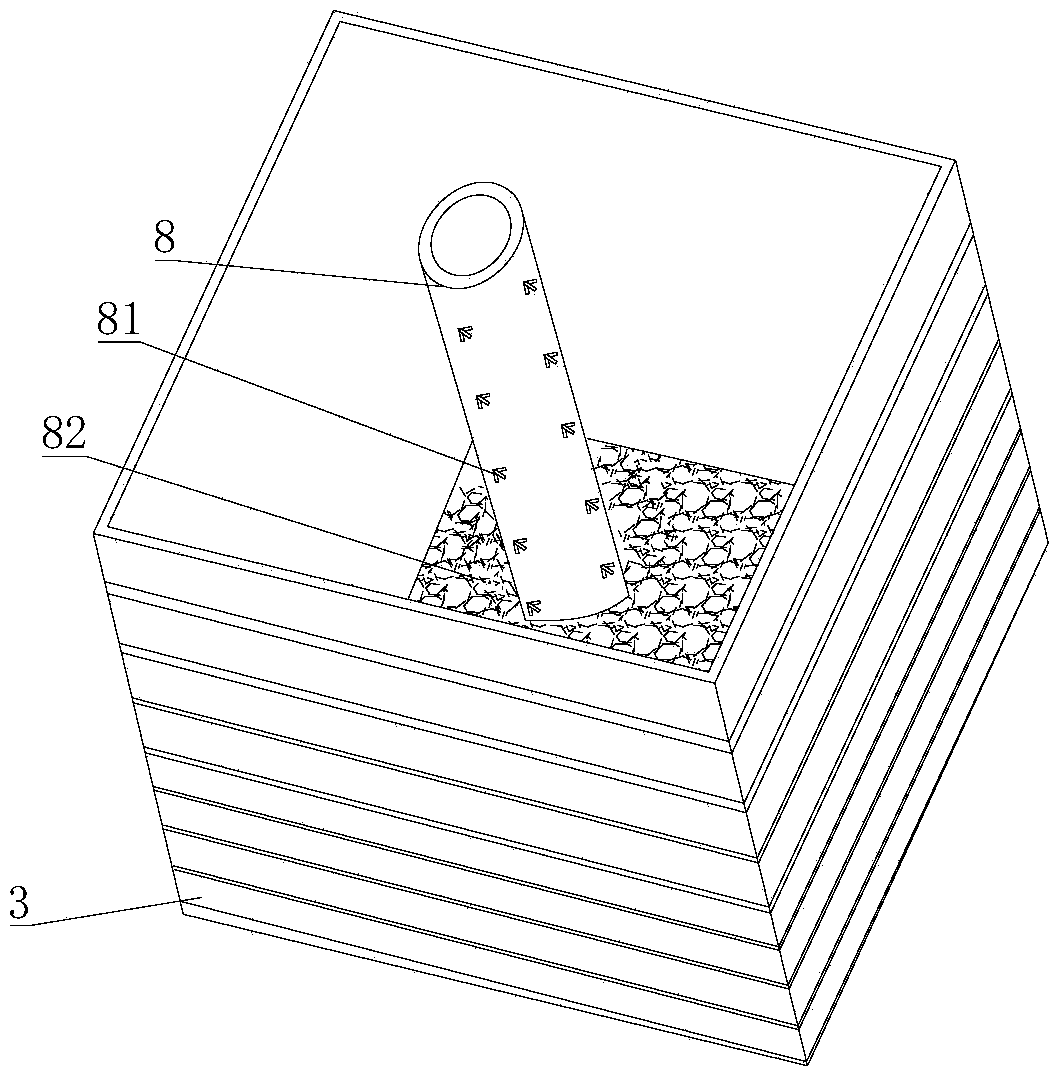

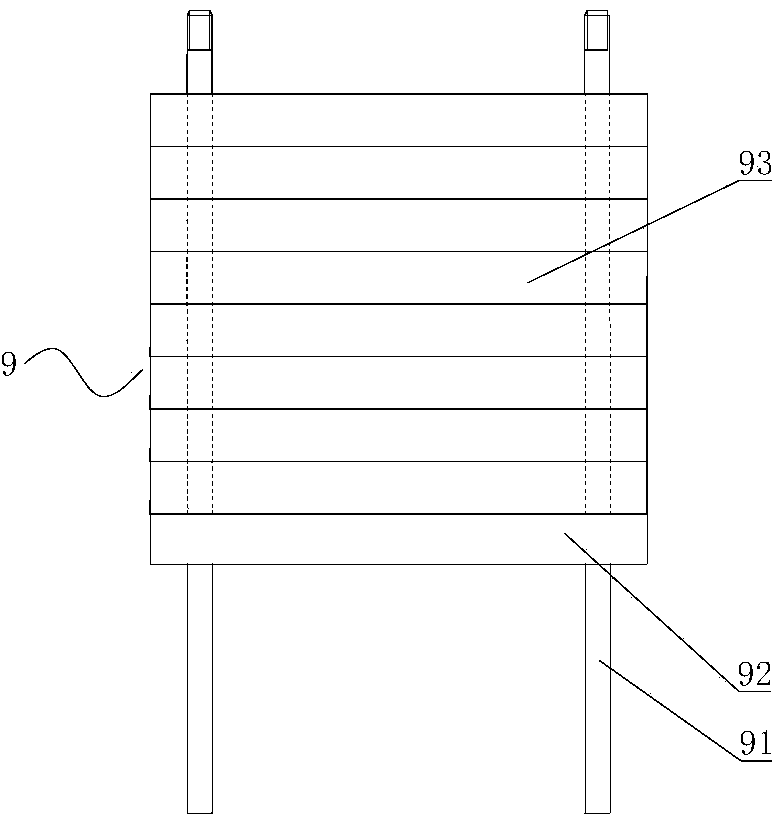

[0041] Such as Figure 1 ~ Figure 6 As shown, the test device for testing dynamic shear characteristics between pipe piles and grouted soil according to the present invention includes a vibration platform 1, a pipe pile model test box set on the vibration platform 1, and a pipe pile loading load The loading mechanism 9 and the monitoring system. In this embodiment, the loading mechanism 9 includes a mass 93, a support frame 91, and a bearing plate 92 for placing the mass 93. The bearing plate 92 is provided with a supporting frame 91 Through the mounting hole 94, the bottom of the support frame 91 is welded and fixed to the end plate of the pipe pile. Four support frames 91 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com