Test bed for measuring compaction characteristics of coal seam roof caving natural renewal

A coal seam roof and test bench technology, which is applied in the testing, measuring devices, instruments, etc. of machine/structural components, can solve the problem of inability to determine the stability of rock blocks, the degree of cementation and strength indicators, the loss of the meaning of compression of discrete rock blocks, and the inability to Problems of rock sample stability, degree of cementation and determination of strength indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

[0028] The present invention provides a coal seam roof caving natural regenerative compaction test bench. In order to make the purpose, technical scheme and advantages of the present invention clearer and clearer, the following will combine the accompanying drawings and specific test steps to focus on the formation process of the regenerative roof The present invention is further described in detail.

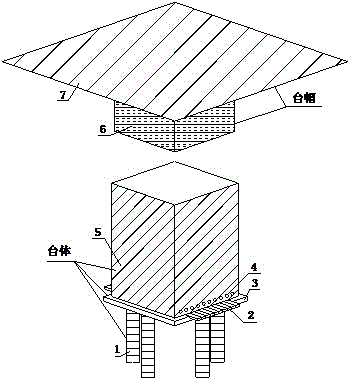

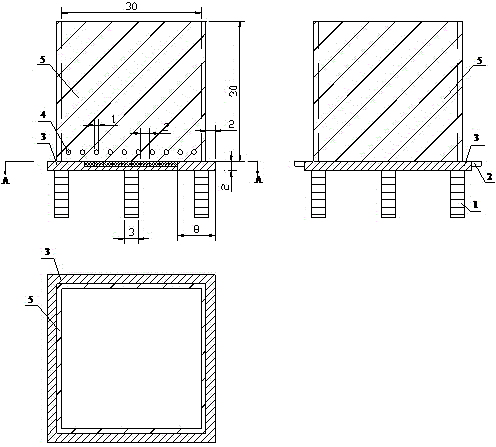

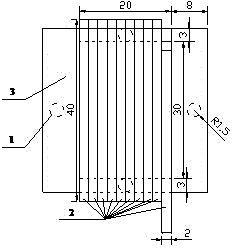

[0029] A coal seam roof caving natural regenerative compaction test bench, which consists of two parts: a platform cap and a platform body. The entity 6 and the loading plate 7 are composed.

[0030] The specific test steps are as follows:

[0031] (1) Spread the coal gangue collected from the field on the bottom of the test bench shell 5 according to the designed block size, with a thickness of 0.5cm, and connect the connecting wires of the miniature stress sensors to the microcomputer through the lead holes 4 opened on both sides of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com