Check valve

A one-way valve, valve body technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of failure, wear and leakage of spring, complex structure of ordinary one-way valve, etc., to increase the tension and solve the problem of poor sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

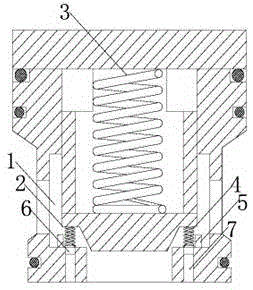

[0012] A one-way valve, comprising a valve body 1 and a valve core 2 installed in the valve body, the bottom surface of the valve core is provided with a supporting spring 3, the inner wall surface of the inlet of the valve body is provided with a first elastic member 4, the first A baffle plate 5 is provided on the inner wall of the valve on the opposite side of the elastic member to the inlet. Since the elastic piece is also designed on the top surface of the valve core, the upward pulling force of the valve core is increased, which solves the problem of medium backflow caused by poor sealing and valve core jamming during the locking process of the check valve.

[0013] A supporting rod 6 is arranged at the joint between the above-mentioned first elastic member and the inner wall surface, and the top end of the supporting rod is in the small hole 7 on the inner wall surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com