System and method for on-line monitoring and modulating slurry pH

A ph meter and controller technology, which is applied in the process of adding pulp raw materials, fiber raw material processing, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve the problems of difficult pH measurement and control, and achieve the elimination of hazards and reduction of Operational deviation, effects of contact avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

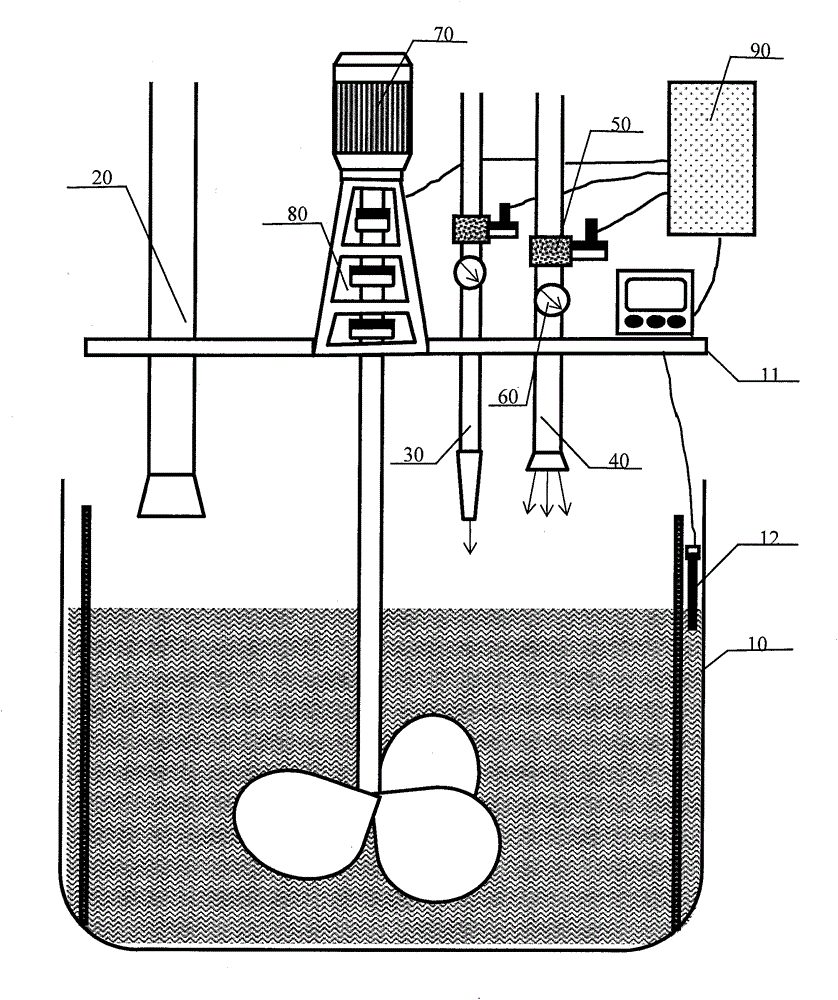

[0028] In this embodiment, a system for online monitoring and adjusting slurry pH includes a beating device, a white water adding device 20 , an automatic sulfuric acid adding device 30 , an automatic pure water adding device 40 , a pH meter 11 , and a central controller 90 . The controller is connected with pH meter 11, speed changer 80, sulfuric acid automatic adding device 30 and pure water automatic adding device. Wherein the beating device is made up of engine 70, speed changer 80, rotating shaft, blade, casing and inner layer filter screen 10. Flow meter 60 and electromagnetic valve 50 are all equipped with on the pipeline of sulfuric acid automatic adding device and pure water automatic adding device. The filter screen is close to the box body, and can only allow the entry and exit of the solution but not the glass fiber. The probe 12 of the pH meter 11 is located between the box body and the inner layer filter screen, and adopts a design similar to a buoy.

[0029] Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com