A yarn feeding device capable of adjusting the density of yarn division

A yarn separation and density technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve problems affecting the quality of weaving products, lack of yarn feeding stability, slipping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below, in conjunction with the accompanying drawings, the specific implementation manners of the present invention will be introduced.

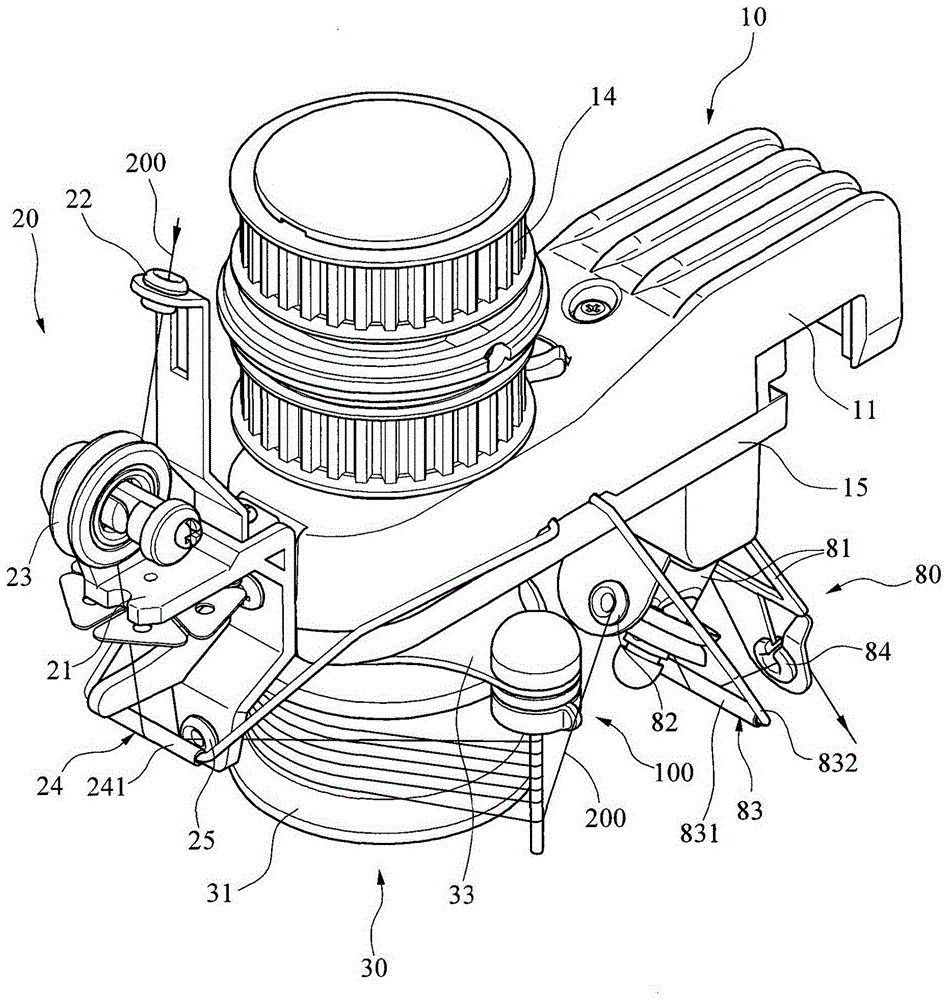

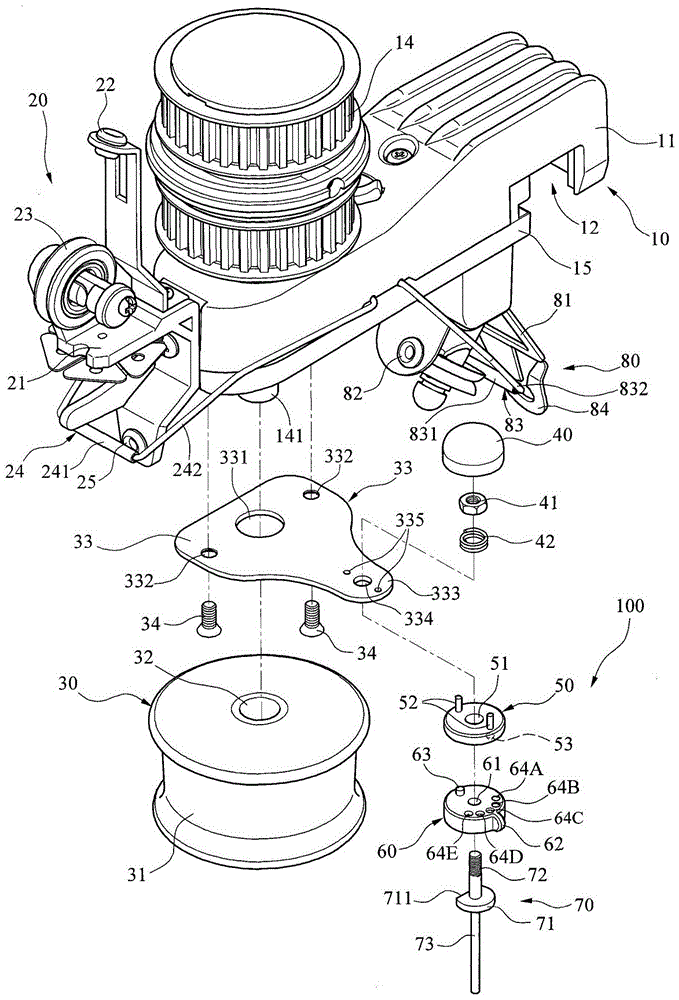

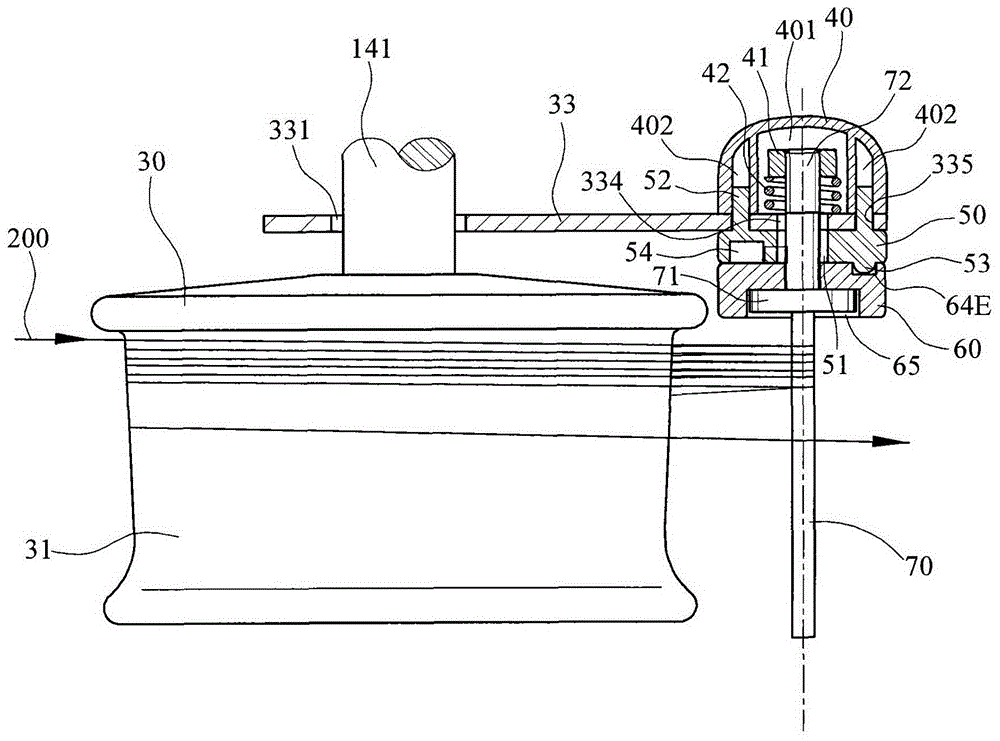

[0053] Such as Figure 6 to Figure 11 As shown, the present invention is a kind of yarn feeding device capable of adjusting the density of divided yarns, comprising:

[0054] Yarn feeding wheel 02 and yarn splitting device 03, the yarn splitting device 03 is arranged on one side of the yarn feeding wheel 02, both the yarn feeding wheel 02 and the yarn splitting device 03 are installed on the horizontal seat 01 of the frame; the upper cover of the yarn feeding wheel 02 is fortified dust cover 021;

[0055] The yarn dividing device 03 includes a core rod 031, which is divided into upper core rod 0311, middle core rod 0312 and lower core rod 0313 from top to bottom, and the central axis of the upper core rod 0311 along the rod length direction is a vertical line , the central axis of the middle section of the core rod 0312 and the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com