Polyvinyl chloride / polyurethane elastomer medical material and preparation method thereof

A technology of polyurethane elastomer and polyvinyl chloride, which is applied in the field of medical polyvinyl chloride/polyurethane elastomer and its preparation, can solve the problems of poor cold resistance, prolong the storage time of blood, and rarely pay attention to the cold resistance of materials, and achieve superior cold resistance sexual effect

Inactive Publication Date: 2015-02-25

上海新上化高分子材料有限公司

View PDF6 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, the current research on the blending of PVC and TPU is mainly focused on improving the mechanical properties, heat resistance, and solvent resistance of the material through the blending of the two, and rarely pays attention to the cold resistance of this type of material; TPU can effectively improve the performance of PVC materials. Cold resistance, if the storage temperature of the material is lowered to -50°C to -60°C, the storage time of blood will be greatly extended, which has great clinical medical value

In addition, cold-resistant plasticizers are rarely added in the selection of plasticizers. Therefore, the cold resistance of the obtained materials is poor, and it is difficult to meet the needs of normal use at -50°C to -60°C; moreover, the currently obtained PVC / TPU blend materials are mainly used in cables, pipes and leather products, etc. There are almost no medical materials that can be used for low temperature storage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

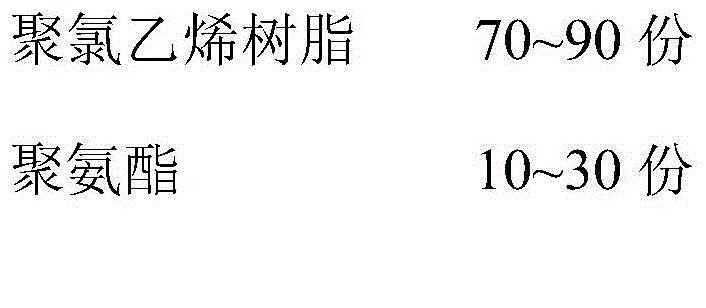

Embodiment 1~2

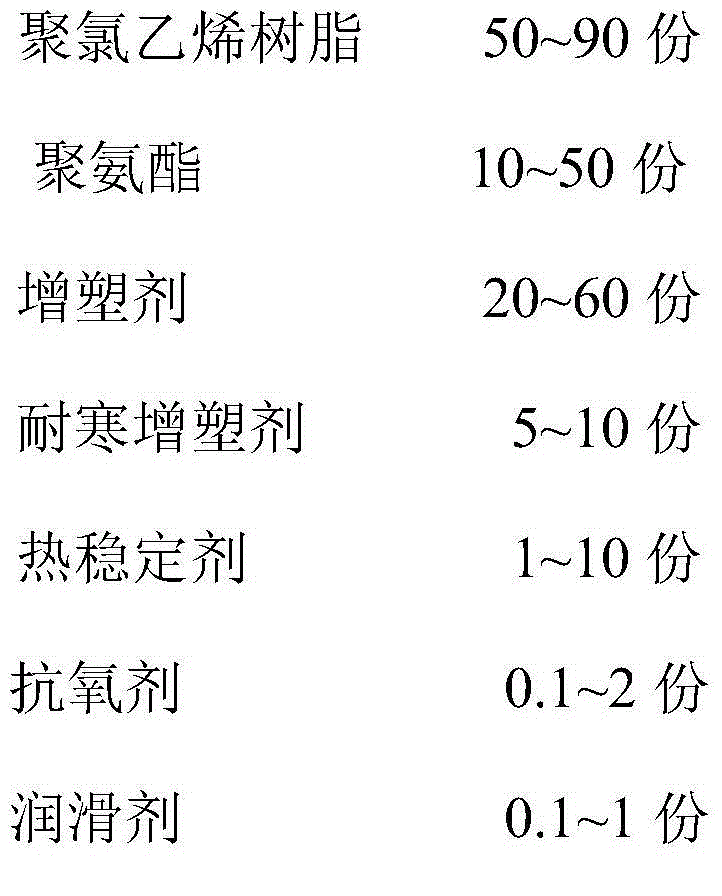

[0024] Components and parts by weight proportioning table 1:

[0025] Table 1

[0026]

[0027] Preparation method: Premix each component in a kneader at 130°C to obtain a premix;

[0028] The above-mentioned premixed material is put into a two-stage extruder, plasticized, extruded and granulated at 150°C to obtain a product. The test performance is shown in Table 2.

[0029] Table 2

[0030] Performance

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a polyvinyl chloride / polyurethane elastomer medical material and a preparation method thereof. The polyvinyl chloride / polyurethane elastomer medical material comprises the following components by weight: 50-90 parts of polyvinyl chloride resin, 10-50 parts of polyurethane, 20-60 parts of a plasticizer, 5-10 parts of a cold resistant plasticizer, 1-10 parts of a heat stabilizer, 0.1-2 parts of an antioxidant and 0.1 -1 parts of a lubricant. The polyvinyl chloride / polyurethane elastomer material provided by the invention has superior cold tolerance, and can be used for a long time at 50 -60 DEG C according to GB / T5470-2008 standard test, and can be used in the manufacture of packaging material for blood bags or other blood products, and other the medical materials.

Description

technical field [0001] The invention relates to a medical polyvinyl chloride / polyurethane elastomer and a preparation method thereof. Background technique [0002] Plasticized polyvinyl chloride (PVC) has the advantages of good air permeability, simple processing technology, and low production cost. It is the main material for making disposable infusion devices, especially in blood preservation materials. But at the same time, the infusion (blood) bag made of PVC material has poor flexibility at low temperature during storage, especially when it is obviously hardened below -20°C, it is easy to cause the bag to break. At present, the low temperature storage temperature can only reach -30°C ~ -40°C ℃, which greatly limits its application. Thermoplastic polyurethane elastomer (TPU) has the advantages of good cold resistance (low temperature embrittlement temperature below -60°C), good biocompatibility, anticoagulation, high strength, good toughness, etc., and has a wide range ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/06C08L75/04C08L75/06C08L75/08C08K13/02C08K5/00C08K5/11C08K5/12C08K5/1515C08K5/526C08K5/09

CPCC08L27/06C08L75/04C08K13/02C08K5/00C08K5/11C08K5/12C08K5/1515C08K5/526C08K5/09

Inventor 唐艳芳薛建民王芹

Owner 上海新上化高分子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com