Rotary type self-unloading conveying belt device for ship

A conveyor belt and ship technology, which is applied in the field of ship cargo self-unloading device, can solve the problems affecting the normal operation and navigation safety of the ship, the transmission frame is too long, the danger of strong winds and waves, etc., and achieve the effect that is conducive to safe driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

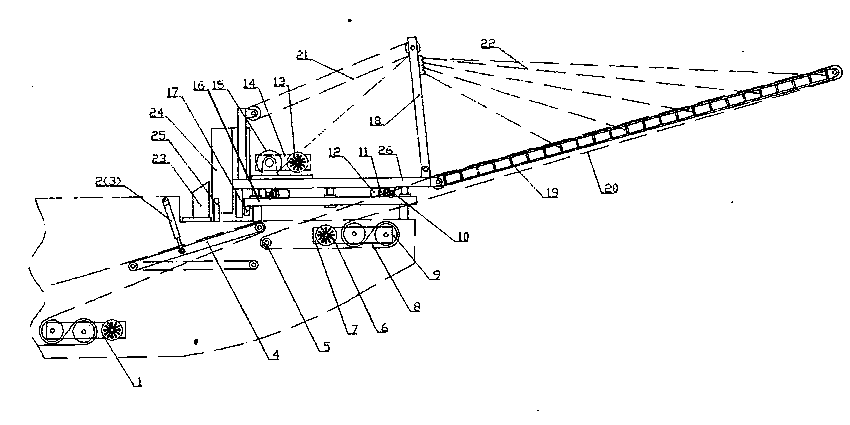

[0012] Referring to the accompanying drawings: the designed ship rotary self-unloading conveyor belt device is composed of a discharge conveying part and an infeed conveying part. The discharge conveying part is set on the surface of the bow, and the infeed conveying part is set in the cabin. Described discharge conveying part comprises: the circular boss 16 that is set on the bow deck, and the top of boss is provided with trapezoidal track, and this track surface is connected with the bottom of rotating device main frame 26 by driving roller 10, and wherein driving roller 10. The cycloid reducer 11 is connected with the main shaft gear of the rotating motor 12, so that the main frame 26 of the rotating device is driven to rotate 360° on the surface of the trapezoidal track on the top of the circular boss 16 through the rollers, so that the frame body can be realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com