Degassing and aroma recovery device

A recovery device and aroma technology, which is applied in the field of degassing and aroma recovery devices, can solve the problems of low aroma recovery efficiency, large floor space, loss of components, etc., and achieve the effects of simple structure, small equipment floor area, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below:

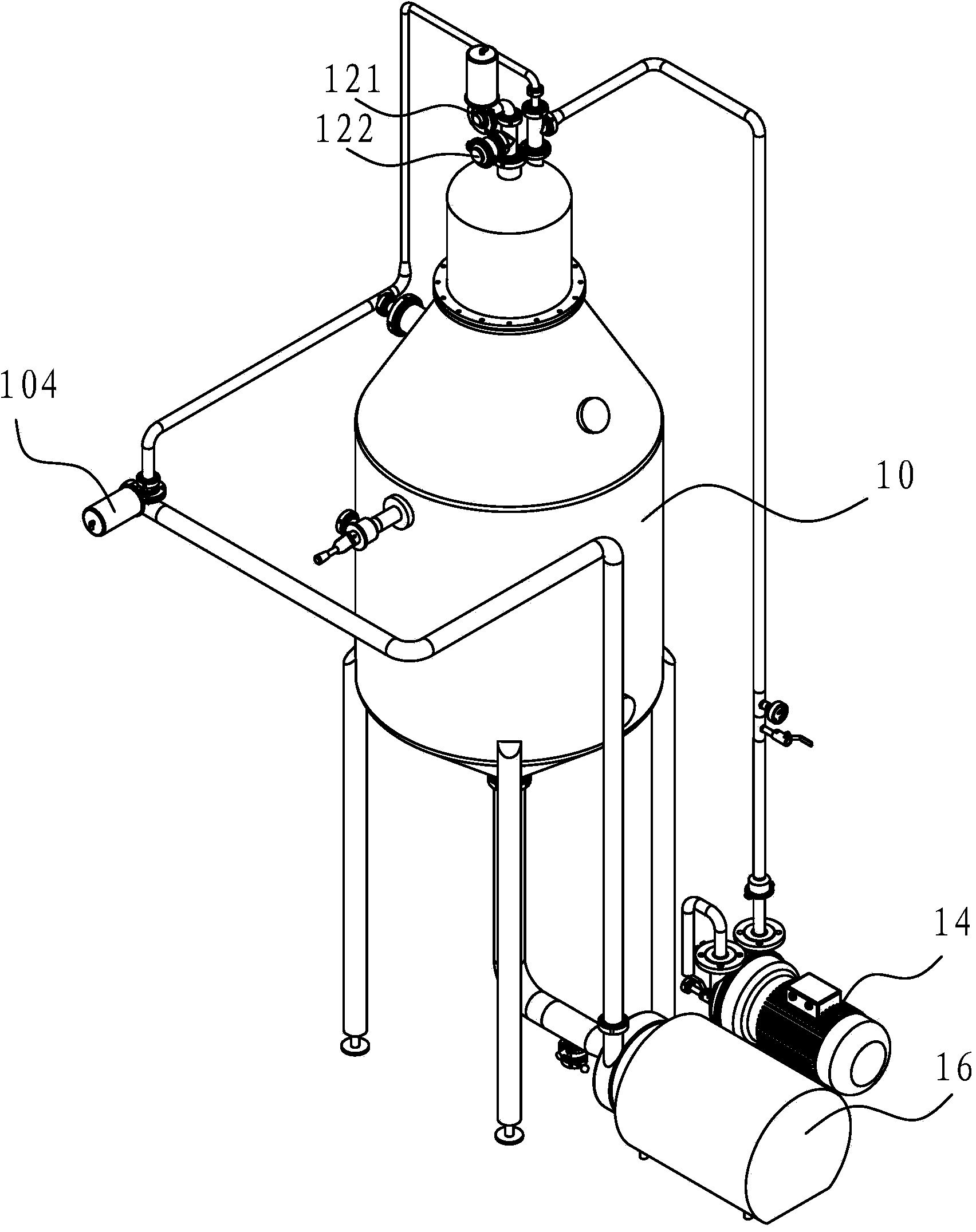

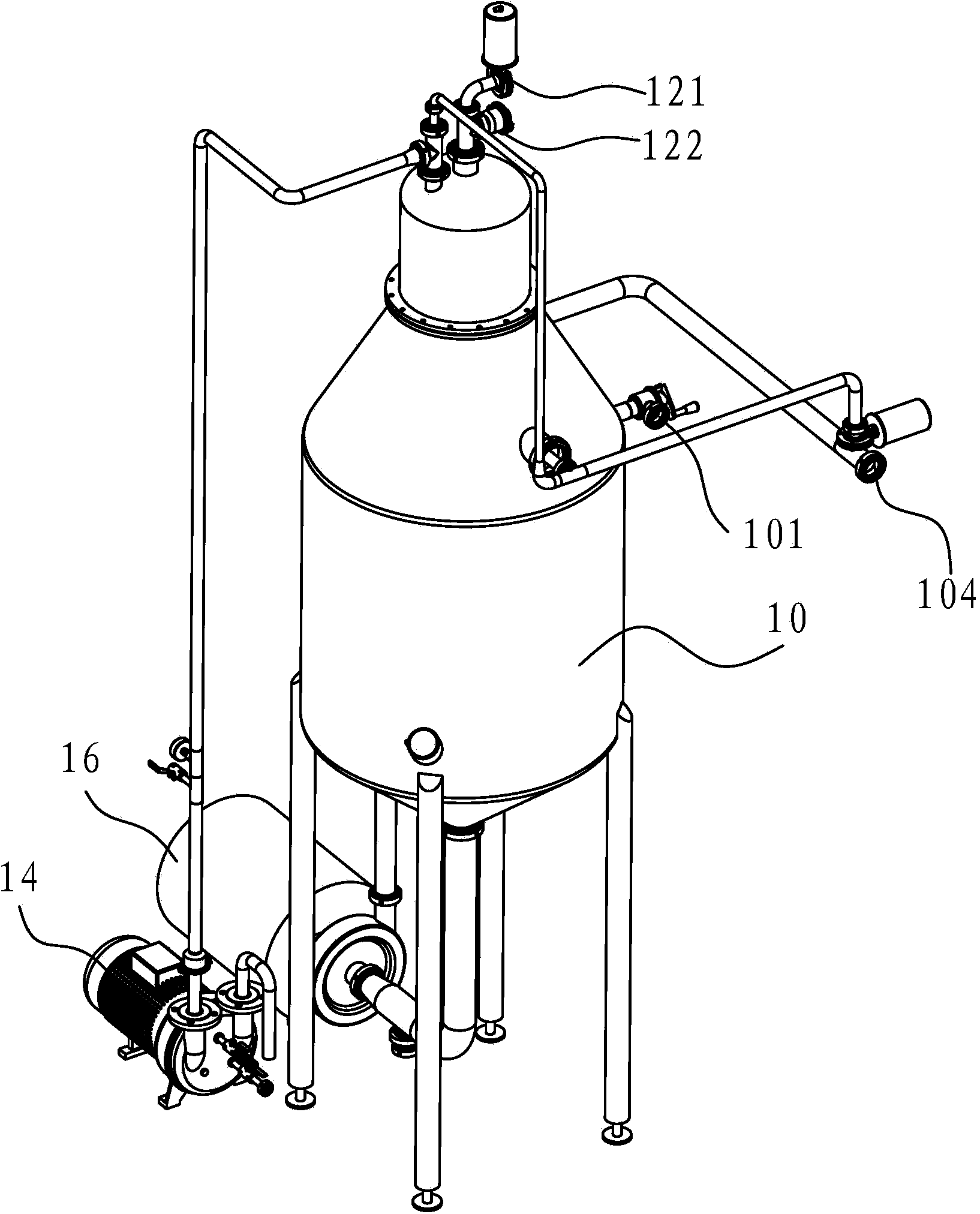

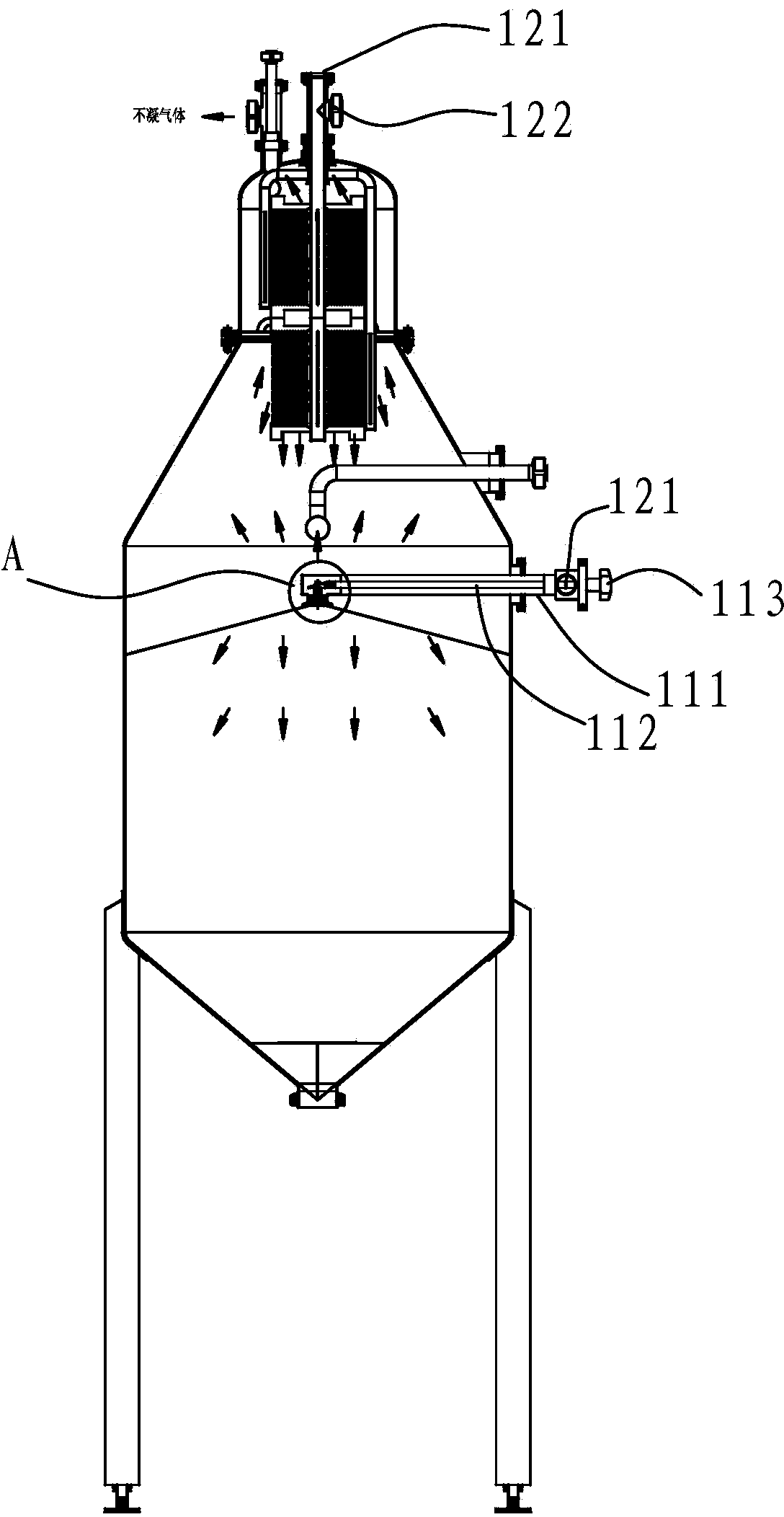

[0025] Such as Figure 1 to Figure 3 As shown, a degassing and aroma recovery device, which includes a degassing tank 10, and a feed port 110 communicated with the degassing tank 10 is located in the degassing tank 10 and connected to the feed port 110 Connected spray device 110, the upper end of the degassing tank 10 is provided with an air outlet 102 communicating with the vacuum pump 14, the lower end of the degassing tank 10 is connected with the discharge pump 16, and the degassing tank 10 is also provided with a discharge port 104 , a heat exchange device 120 is provided between the air outlet 102 and the spray device 110 .

[0026] The degassing and aroma recovery device installs the heat exchange device 120 in the degassing tank 10 and is located above the spraying device 110. The vacuum pump 14 extracts the air in the degassing tank 10 through the air outlet 102 to make the degassing tank 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com