Thrust sinking material control system of bulking machine

A material control system and control system technology, applied in the field of feed processing equipment, can solve problems such as deterioration, waste of water quality, uneven pressure distribution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

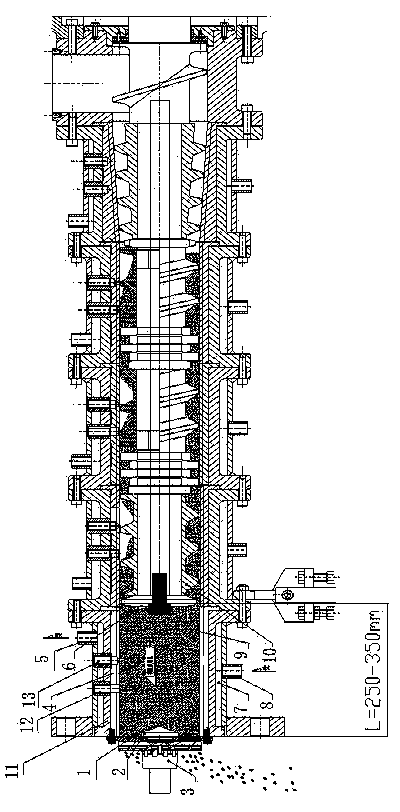

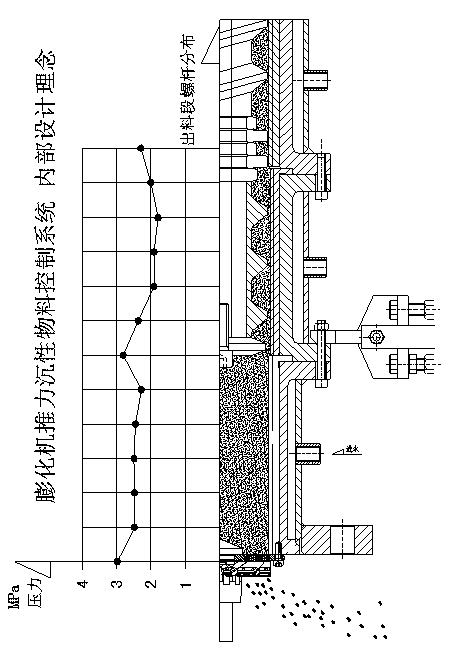

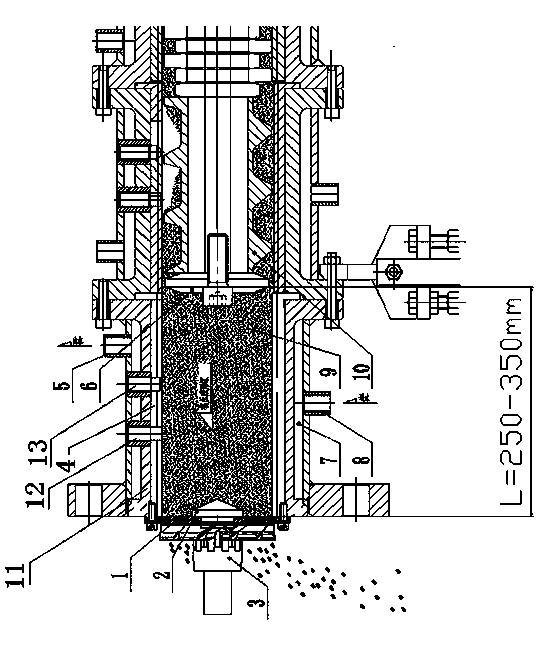

[0018] Example 1 : see figure 1 , figure 2 , image 3 , an extruder thrust sinking material control system, the control system includes a screw sleeve and a thrust screw 10 arranged inside the screw sleeve, a template 1 is provided at the discharge end of the screw sleeve, and a cutting device 3 is provided in front of the template , the gelatinized feed is cut into different sizes according to the needs by the cutting device, the splitter cone 2 is fixedly connected in the middle of the template, and the gelatinized feed enters the mold hole of the template under the diversion action of the splitter cone 2 , an extrusion forming area 9 is provided in the area where the distance from the template in the screw sleeve is L, and the extrusion forming area is arranged between the template 1 and the thrust screw 10, and the thrust screw 10 close to the extrusion forming area is fixed with pressure ring6. The overall structural design of this technical solution is ingenious, ...

Embodiment 2

[0019] Example 2 : see figure 1 , figure 2 , image 3 , as an improvement of the present invention, the distance L is 250-350mm, that is, the length of the extrusion forming zone is set to 250-350mm, and the extrusion forming zone of this length can ensure that the gelatinization degree of starch is ≥ 85%, The urease activity of soybeans is ≤0.2Ua, and the sinking rate of the formed material is ≥95%, meeting the requirements of the industry standard, and the rest of the structure and advantages are exactly the same as those in Example 1.

Embodiment 3

[0020] Example 3 : see figure 1 , figure 2 , image 3 , as an improvement of the present invention, the screw sleeve 11 is provided with a spacer 7, and the spacer 7 is provided with a water outlet 5 and a water inlet 8, which can be set according to the needs. The spacer is provided with circulating cooling water, which is convenient The temperature of the inner sleeve and the material drops, greatly reducing the secondary expansion and pressure of the material, so that the extrusion density of the material is greatly improved. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com