Bipolar alkaline water electrolysis unit and electrolytic cell

A water electrolysis, bipolar technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of unsatisfactory performance of oxygen evolution electrodes, rising oxygen evolution overvoltage, inappropriate specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0227] The present invention will be described below based on examples, but the present invention is not limited to the examples.

[0228] (Example 1)

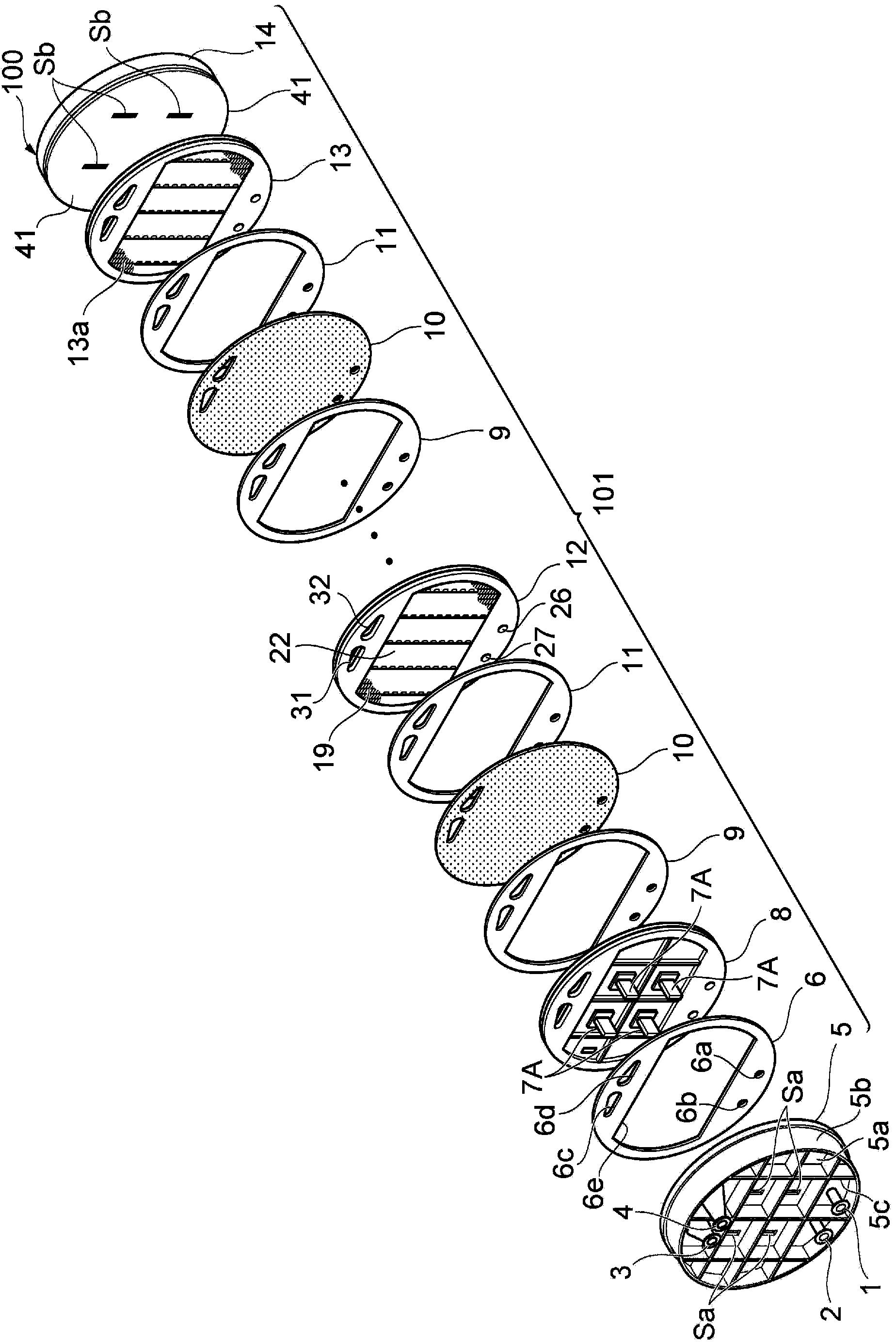

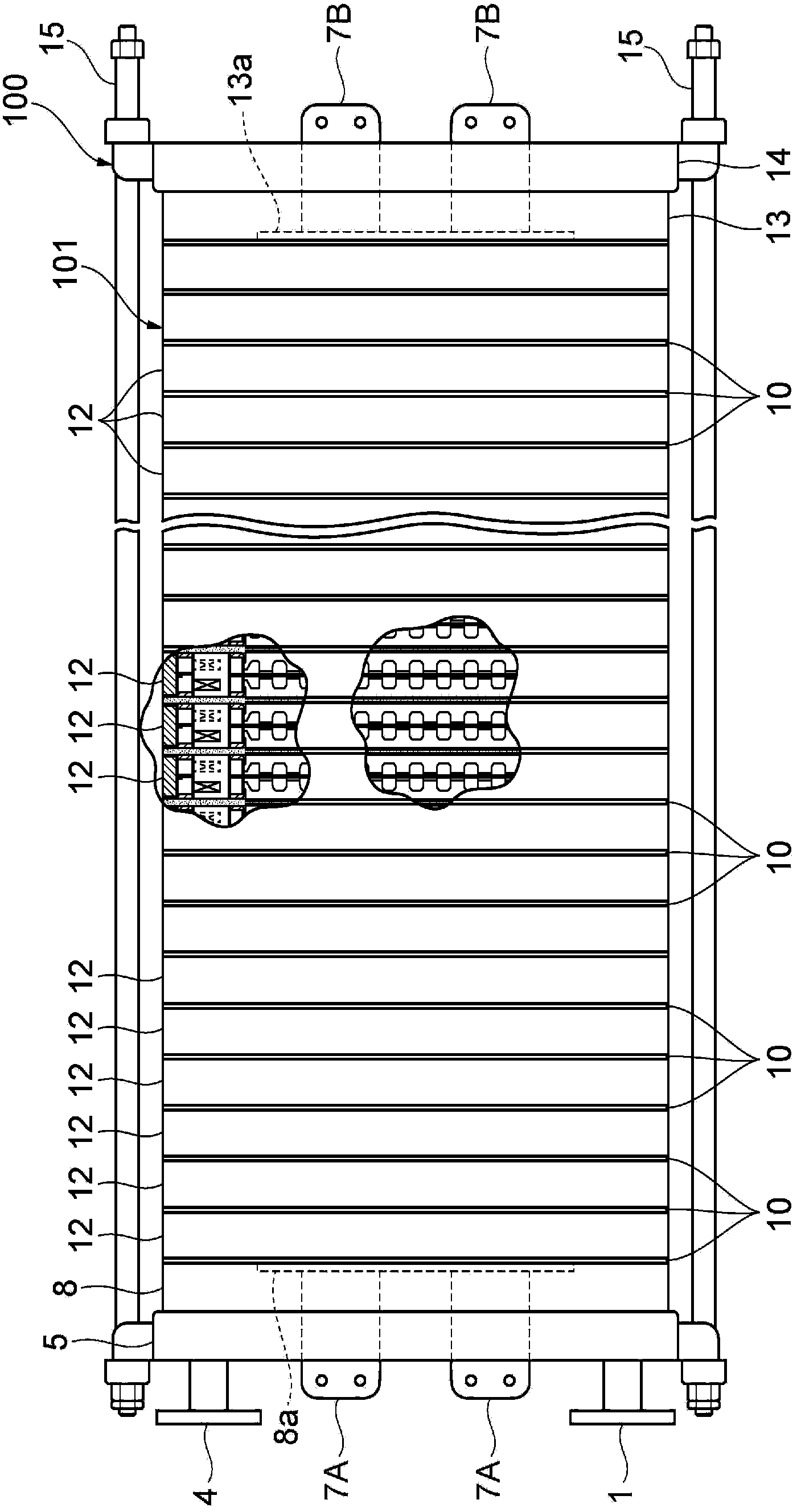

[0229] use 3 image 3 and Figure 4 The electrolysis unit 12 shown in the first embodiment is the same as figure 1 In this way, the pressing flange 5, the pressing flange gasket 6, and the anode terminal unit 8 are arranged at one end, and the cathode terminal unit 13 is arranged at the other end, and the tail end pressing flange 14 with the insulating plate 41 installed is installed as figure 2 The same electrolytic cell 100 .

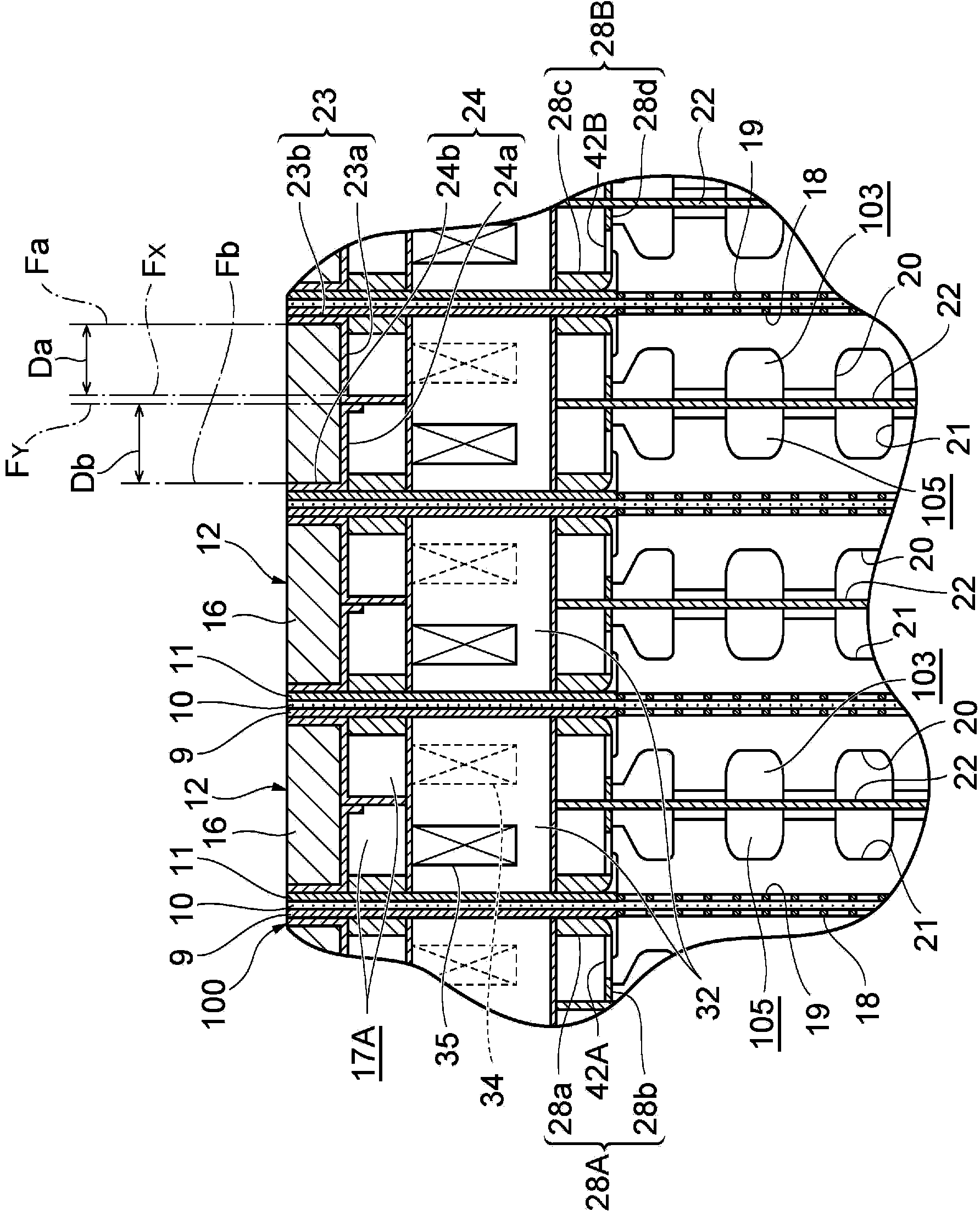

[0230] The electrolysis unit 12 is a circle with an outer diameter of 700mm, and the area of the anode 18 and the cathode 19 is 0.25m 2 . In addition, the depth of the anode chamber 103 (anode chamber depth) is 15 mm, the depth of the cathode chamber 105 (cathode chamber depth) is 15 mm, and the materials of the anode side flange 23 and the cathode side flange 24 are both nickel. The thicknes...

Embodiment 2

[0238] use 3 Figure 12 and Figure 13 The electrolysis unit 12 shown in the first embodiment is the same as figure 1 In this way, the pressing flange 5, the pressing flange gasket 6, and the anode terminal unit 8 are arranged at one end, and the cathode terminal unit 13 is arranged at the other end, and the tail end pressing flange 14 with the insulating plate 41 installed is installed as figure 2 The same electrolytic cell 100 .

[0239] The electrolysis unit 12 is a circle with an outer diameter of 700mm, and the area of the anode 18 and the cathode 19 is 0.25m 2 . In addition, the depth of the anode chamber 103 (anode chamber depth) was 15 mm, and the depth of the cathode chamber 105 (cathode chamber depth) was 15 mm. Further, anode ribs 20 made of nickel with a height of 15 mm and a thickness of 1.5 mm and cathode ribs 21 made of nickel with a height of 13.5 mm and a thickness of 1.5 mm were attached to the partition wall 22 made of nickel with a thickness of 1 mm ...

Embodiment 3

[0248] Instead of the electrolytic cell 12, use 3 Figure 8 ~ Figure 10 The electrolysis unit 120 shown in the second embodiment is the same as figure 1 In this way, the pressing flange 5, the pressing flange gasket 6, and the anode terminal unit 8 are arranged at one end, and the cathode terminal unit 13 is arranged at the other end, and the tail end pressing flange 14 with the insulating plate 41 installed is installed as figure 2 The same electrolytic cell 100 .

[0249] The electrolysis unit 12 is a circle with an outer diameter of 700mm, and the area of the anode 18 and the cathode 19 is 0.25m 2 . In addition, the depth of the anode chamber 103 (anode chamber depth) is 15 mm, the depth of the cathode chamber 105 (cathode chamber depth) is 15 mm, and the materials of the anode side flange 23 and the cathode side flange 24 are both nickel. The thickness of the nickel partition wall 22 to which the nickel anode rib 20 of 15 mm in height and 1.5 mm in thickness and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com