Hydraulic system for balancing integrated block of slewing reducer

A technology of slewing reducer and hydraulic system, which is applied to cranes, mechanical equipment, fluid pressure actuators, etc. It can solve the problems of slewing reducer gear wear and large assembly clearance, and achieve reliable slewing braking and reduce gear wear degree, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

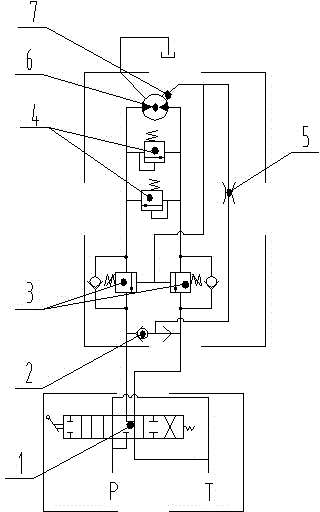

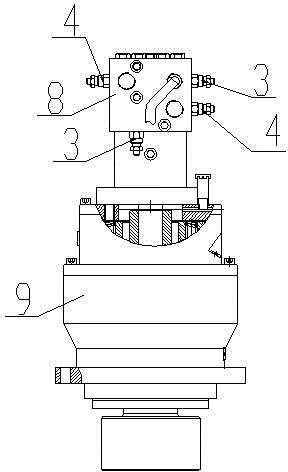

[0008] Now in conjunction with the following drawings, the invention is described in detail.

[0009] see figure 1 , figure 2 , Crane directional control valve 1, shuttle valve 2, balance valve 3, overflow valve 4, damping plug 5 are integrated on manifold 8, while motor 6 and brake 7 are installed on rotary reducer 9. Crane directional control valve 1 is connected to motor 6 through shuttle valve 2, two balance valves 3, and two relief valves 4, and damping plug 5 is connected in series between the control oil circuit of shuttle valve 2 and the control oil circuit before brake 7 ; The control oil circuits of the two balance valves 3 are connected in parallel and then connected in parallel with the control oil circuits of the shuttle valve 2;

[0010] When the rotary action starts, stops and is impacted, the working hydraulic oil needs to reach the control port in the brake 7 and the control port in the balance valve 3 through the damping plug 5, so that the brake 7 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com