A prefabricated external wall thermal insulation system and its assembly method

An external thermal insulation and prefabricated technology, applied in thermal insulation, climate change adaptation, building components, etc., can solve the problems of high level requirements, generation of mortar waste, low-strength thermal insulation materials, etc., to shorten the construction period, facilitate installation, Easy to change the effect of decorative seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. However, the examples given are not intended to limit the present invention.

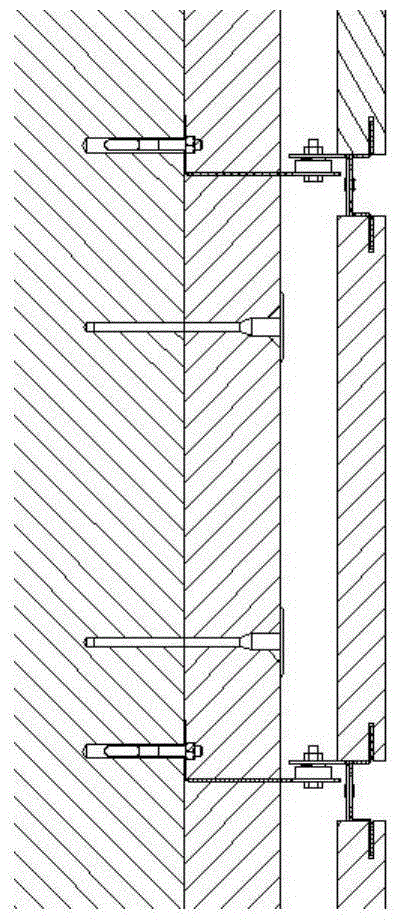

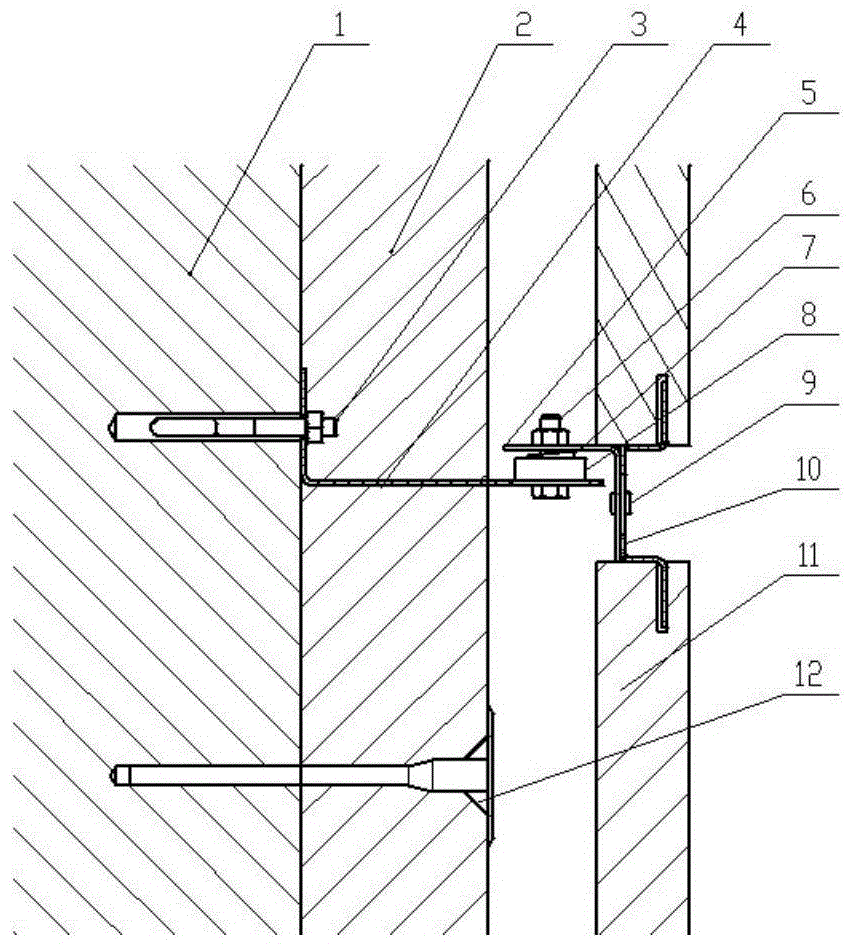

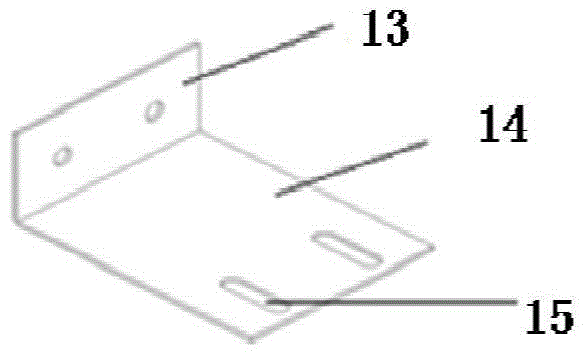

[0064] A prefabricated external wall insulation system, such as figure 1 , 2 shown, including: image 3 As shown, the support 4 is an "L" shaped metal piece, the fixed side of the support 4 is fixed on the wall 1 through the connector c3, the connecting side of the support 4 is connected to the keel 5, and the support 4 The length of the connecting edge is greater than the thickness of the thermal insulation material 2. The slot hole at the end of the support leaks out of the surface of the thermal insulation material by at least 20 mm, and the end of the connecting edge of the support 4 has a longitudinal slot a15 perpendicular to the direction of the wall 1. .

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com