Single-furnace multicolor float glass production line

A technology of float glass and production line, applied in the field of single-kiln multi-color float glass production line, which can solve the problems of difficult color change of melting furnace, lower production cost, and long color change cycle, so as to reduce energy consumption of single kiln and avoid pollution , The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

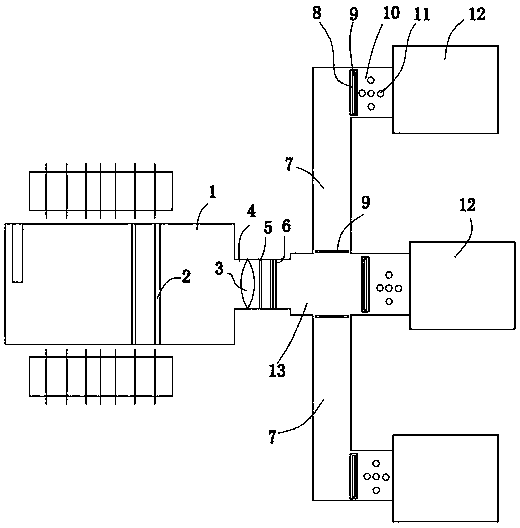

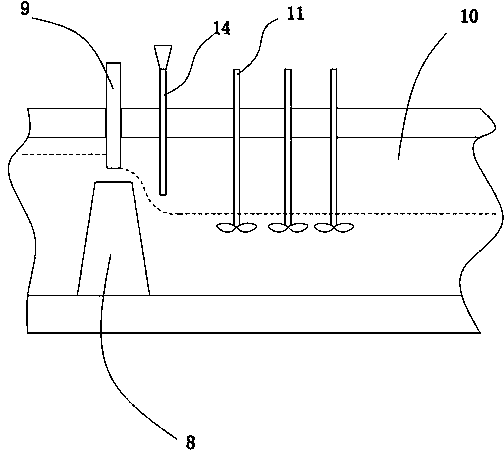

Embodiment 1

[0024] Embodiment 1: A kind of single kiln three-color float glass production line (see attached figure 1 ), including a large-tonnage melting furnace 1, connected to the primary neck 4 of the melting furnace. The melting furnace includes a feeding port, a melting zone, a small furnace, a regenerator, and a clarification chamber, and the clarification chamber is provided with a kiln rim bubbler 2 . A large water bag system 3, a horizontal mixing system 5 and a T-shaped hanging wall 6 are installed at the first-level neck. The first-stage neck is connected with a diversion device. The diversion device has three flow channels for diverting the glass liquid from the first-stage neck. Tin tank and subsequent devices, the sum of the pulling capacity of all runners corresponding to the production line matches the melting capacity of the glass melting furnace. The melting furnace built in this embodiment is 800t / d, and the pulling capacity of the production line corresponding to the...

Embodiment 2

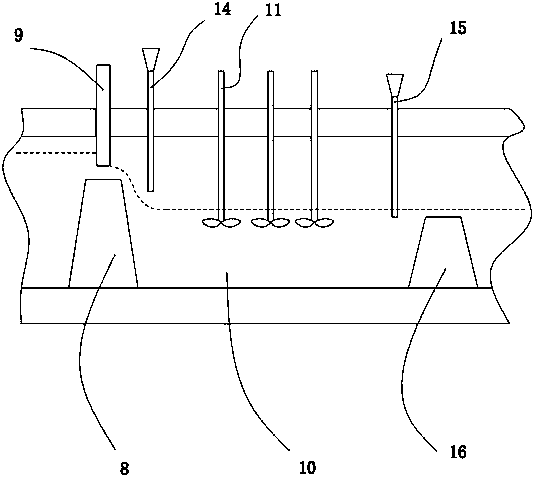

[0027] Example 2: A single-kiln three-color float glass production line, the difference from Example 1 is that a liquid flow kiln ridge 16 is arranged behind the coloring device in the secondary neck, and the height of the liquid flow kiln ridge is smaller than the return liquid The height of the kiln sill of the baffle, and the top surface of the liquid flow kiln sill is lower than the liquid level of the glass liquid at the secondary neck. A liquid pipe 15 is arranged on the front side of the liquid flow kiln sill in the secondary neck, the lower end of the liquid pipe is lower than the top of the liquid flow kiln sill, and the upper end of the liquid pipe is provided with a cover (see attached image 3 ). The number of liquid pipes is 4, arranged side by side in the secondary neck, and across the entire secondary neck. Refer to Example 1 for all the other structures.

Embodiment 3

[0028] Example 3: A single-kiln three-color float glass production line, the difference from Example 2 is that the liquid pipe overlaps with the stirring device of the coloring device, and the stirring device of the coloring device adopts a hollow shaft tube, which is The liquid pipe; the outer wall of the lower part of the shaft pipe is provided with a liquid hole; the stirring blade of the stirring device is fixed on the outer wall of the shaft pipe, and the liquid hole is arranged between the blade and the blade. The injection pipe is obliquely inserted into the secondary neck, the axis of the injection pipe intersects the inclined surface of the kiln sill, and the vertical projection of the outlet of the injection pipe falls on the inclined surface (see attached Figure 4 ). Refer to Example 1 for all the other structures.

[0029] According to the layout conditions of the production line, multiple outlets can be set on the horizontal flow channel, and each outlet is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com