Sewage purification disinfectant and preparation method thereof

A technology for sewage purification and disinfectant, applied in the directions of disinfectants, chemical instruments and methods, botanical equipment and methods, etc., can solve the problem of inability to disinfect sewage, and achieve the effect of good scale stripping effect and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

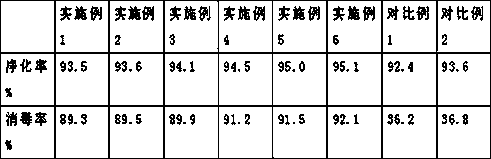

Examples

Embodiment 1

[0021] A sewage purification disinfectant, comprising the following raw materials in parts by mass: 25 parts of aluminum sulfate, 20 parts of diatomaceous earth, 5 parts of tannin, 2 parts of polyethyleneimine, dodecyl dimethyl benzyl 1 part of ammonium chloride, 3 parts of sodium silicate, 40 parts of water;

[0022] A method for preparing a sewage purification disinfectant, comprising the following steps: stirring aluminum sulfate, diatomaceous earth, tannin and water in sequence according to the mass ratio, and gradually adding polyethyleneimine and sodium silicate during the stirring process and dodecyl dimethyl benzyl ammonium chloride, and stir evenly to obtain the finished product of the present invention.

Embodiment 2

[0024] A sewage purification disinfectant, comprising the following raw materials in parts by mass: 27 parts of aluminum sulfate, 23 parts of diatomaceous earth, 6 parts of tannin, 2 parts of polyethyleneimine, dodecyl dimethyl benzyl 1 part of ammonium chloride, 4 parts of sodium silicate, 45 parts of water;

[0025] A method for preparing a sewage purification disinfectant, comprising the following steps: stirring aluminum sulfate, diatomaceous earth, tannin and water in sequence according to the mass ratio, and gradually adding polyethyleneimine and sodium silicate during the stirring process and dodecyl dimethyl benzyl ammonium chloride, and stir evenly to obtain the finished product of the present invention.

Embodiment 3

[0027] A sewage purification disinfectant, comprising the following raw materials in parts by mass: 28 parts of aluminum sulfate, 25 parts of diatomaceous earth, 7 parts of tannin, 3 parts of polyethyleneimine, dodecyl dimethyl benzyl 2 parts of ammonium chloride, 5 parts of sodium silicate, 50 parts of water;

[0028] A method for preparing a sewage purification disinfectant, comprising the following steps: stirring aluminum sulfate, diatomaceous earth, tannin and water in sequence according to the mass ratio, and gradually adding polyethyleneimine and sodium silicate during the stirring process and dodecyl dimethyl benzyl ammonium chloride, and stir evenly to obtain the finished product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com