Process and device for producing concentrated ammonia water by washing ammonia with ammonium phosphate with controllable concentration of product ammonia water

A technology for washing ammonia with ammonia water concentration and ammonium phosphate, which is applied in the field of gas deammonization process in the coking industry. It can solve the problems that the concentration of ammonia gas cannot be guaranteed and the concentration of ammonia water cannot meet the specified requirements, and the concentration of ammonia water in the product can be accurately controlled and adjusted. Flexible and convenient, stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

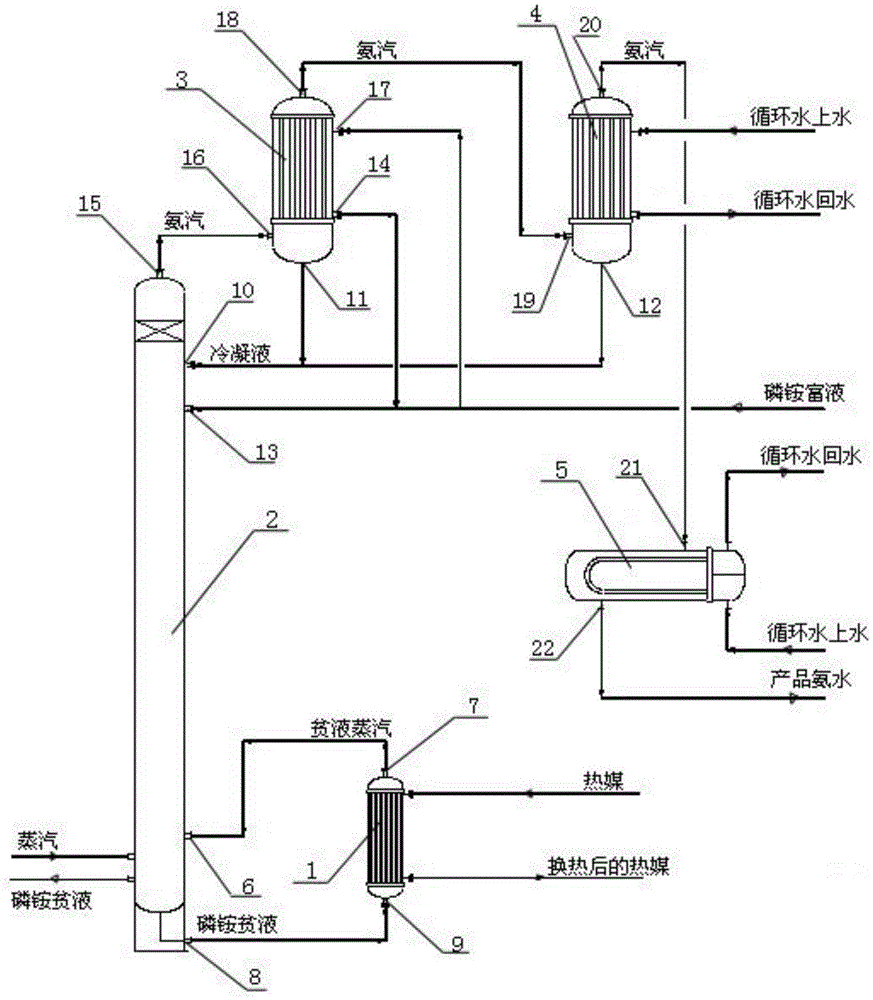

[0030] Such as figure 1 , Is the process flow diagram of this embodiment. In the process of producing concentrated ammonia water by ammonium phosphate washing ammonia, the desorption tower heater 1, ammonium phosphate washing ammonia desorption tower 2, ammonia vapor separator and ammonia vapor condenser 5 are all conventional The settings are not repeated here. The ammonia vapor fractionator in this embodiment is a two-stage fractional fractionator 3 and 4 arranged in parallel, and the ammonia vapor escaping from the top of the first-stage fractionator 3 passes through the lower ammonia vapor inlet 19 of the second-stage fractionator 4 When entering, the condensate (reflux ammonia) of the second-stage condenser 4 merges with the condensate of the first-stage condenser 3 and enters the condensate inlet 10 at the upper part of the desorption tower 2. The ammonia vapor escaping from the top of the second-stage fractionator 4 enters the ammonia vapor inlet 21 of the condenser, and...

Embodiment 2

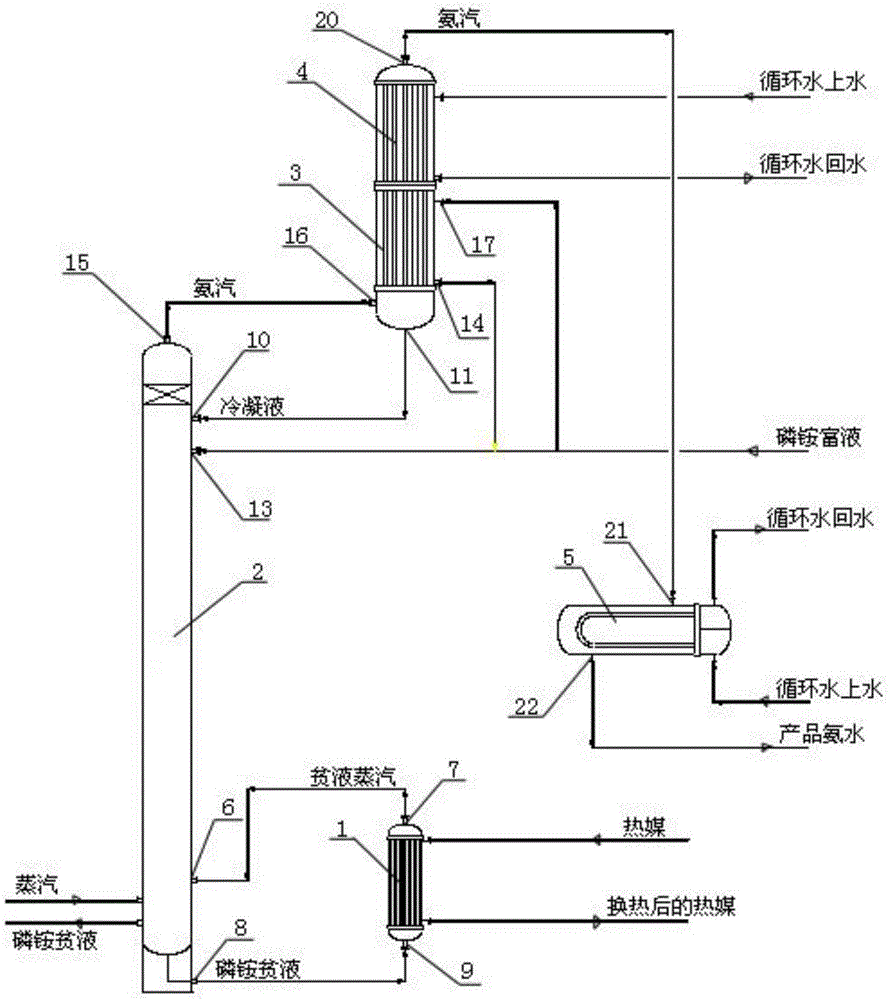

[0032] Such as figure 2 , Is a schematic diagram of the process flow of this embodiment. The ammonia vapor fractionator in this example is a two-stage fractionator 3 and 4 connected up and down. The ammonia vapor from the desorption tower 2 passes through the first stage fractionator 3. It reaches the ammonia vapor outlet 20 at the top of the connected second-stage fractionator 4, and then enters the ammonia vapor inlet 21 of the condenser. The condensate (reflux ammonia) flows out from the condensate outlet 11 at the lower part of the first-stage fractionator and enters the condensate inlet 10 at the upper part of the desorption tower 2. In the first-stage fractionator 3, the ammonium phosphate rich liquid flowing through is used for heat exchange with ammonia vapor. In the second-stage fractionator 4, the heat exchange process with ammonia vapor is realized by circulating water. Dividers 3 and 4 can take tube pass or shell pass. By adjusting the amount of circulating water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com