Forklift bracket cooperatively used with forklift

A technology of forklifts and brackets, applied in the direction of lifting devices, etc., can solve the problems that affect the transfer efficiency, the fork arms come out, and foreign objects cannot be found intuitively, so as to achieve the effect of improving transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

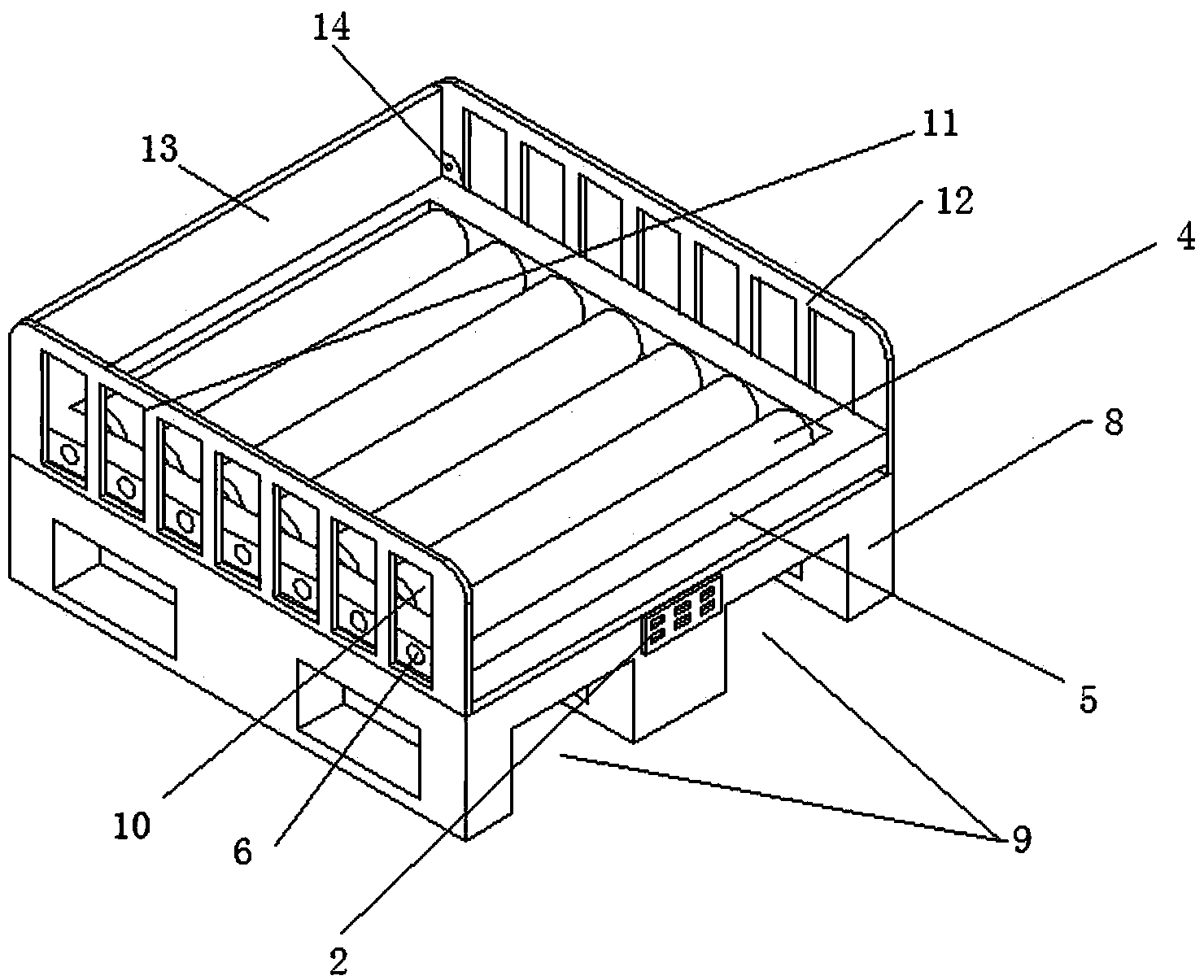

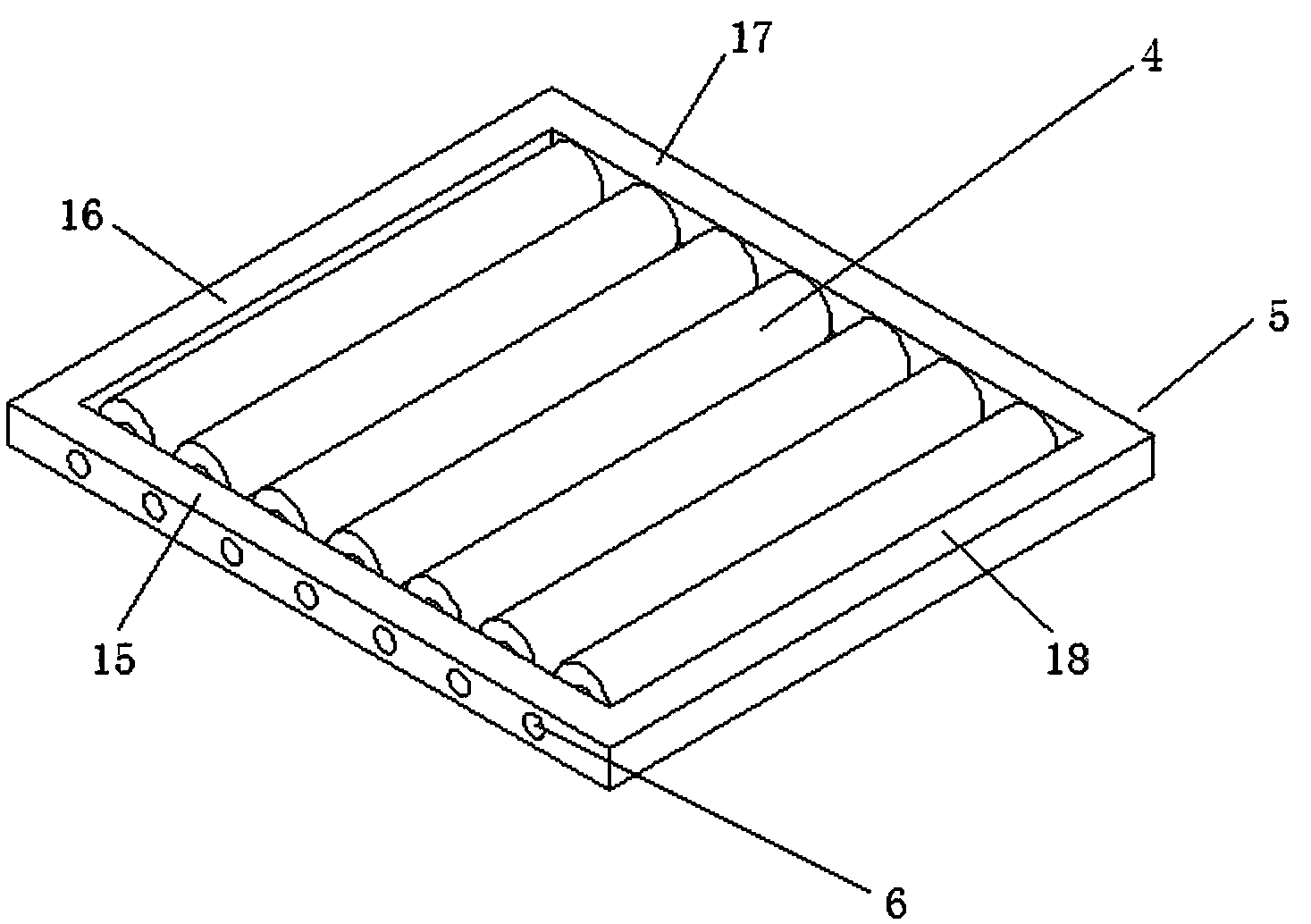

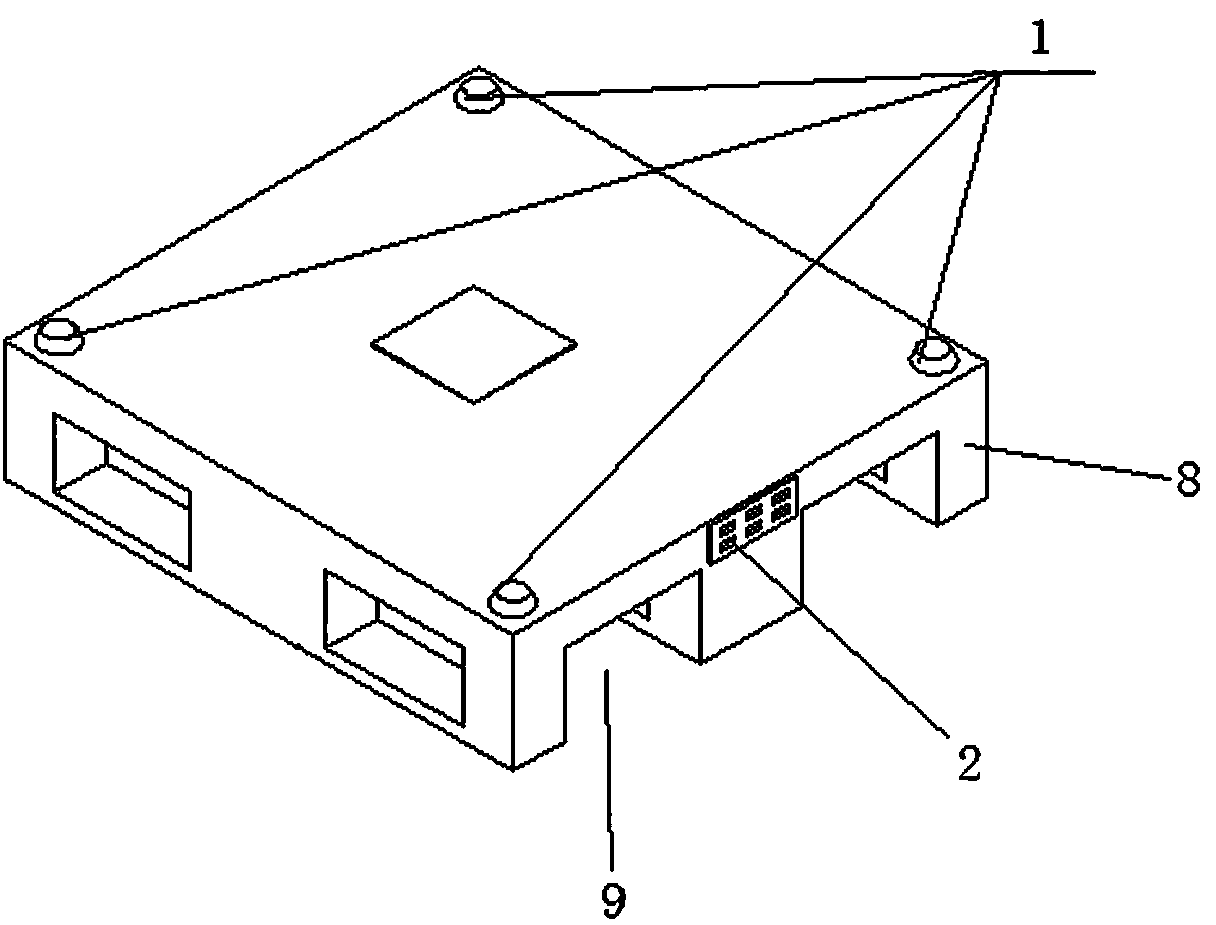

[0018] An example of a forklift bracket Figure 1~3 Shown: It includes a bracket body for being lifted by the fork arms of a forklift from back to front. The bracket body includes a base frame 8 provided with a fork arm slot 9 and a support frame 5 arranged on the upper side of the base frame 8. The fork arm slot is used to insert the fork arm from back to front. The support frame includes a left support arm 15, a rear support arm 18, a right support arm 17 and a front support arm 16, which are sequentially connected end to end. Each support arm encloses a box-shaped structure. The support frame is sequentially arranged with seven rotations in the front and rear directions. The supporting rollers 4 whose axes extend in the front-rear direction, the roller shafts 6 of each supporting roller are rotatably assembled on the left and right supporting arms. A weighing mechanism is arranged between the bottom frame and the support frame. The weighing mechanism includes four weighing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com