Sliding type loading mechanism applied to automatic pipettor tip loader

A pipette tip and loading mechanism technology, which is applied in the field of loading mechanism and sliding loading mechanism, can solve the problems of low loading efficiency, and achieve the effects of high working efficiency, compact structure, and accurate feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The pipette tip automatic loader in the present embodiment is the pipette tip automatic loader in the prior art, including frame, vibration plate, direct vibration, movable base, loading tray and loading in the present invention mechanism; its specific installation relationship is:

[0029] Both the vibrating plate and the movable base are installed on the frame, the vibrating plate is connected with the direct vibration, the direct vibration is connected with the loading mechanism, the loading plate is set on the movable base, and the loading plate is located under the loading mechanism.

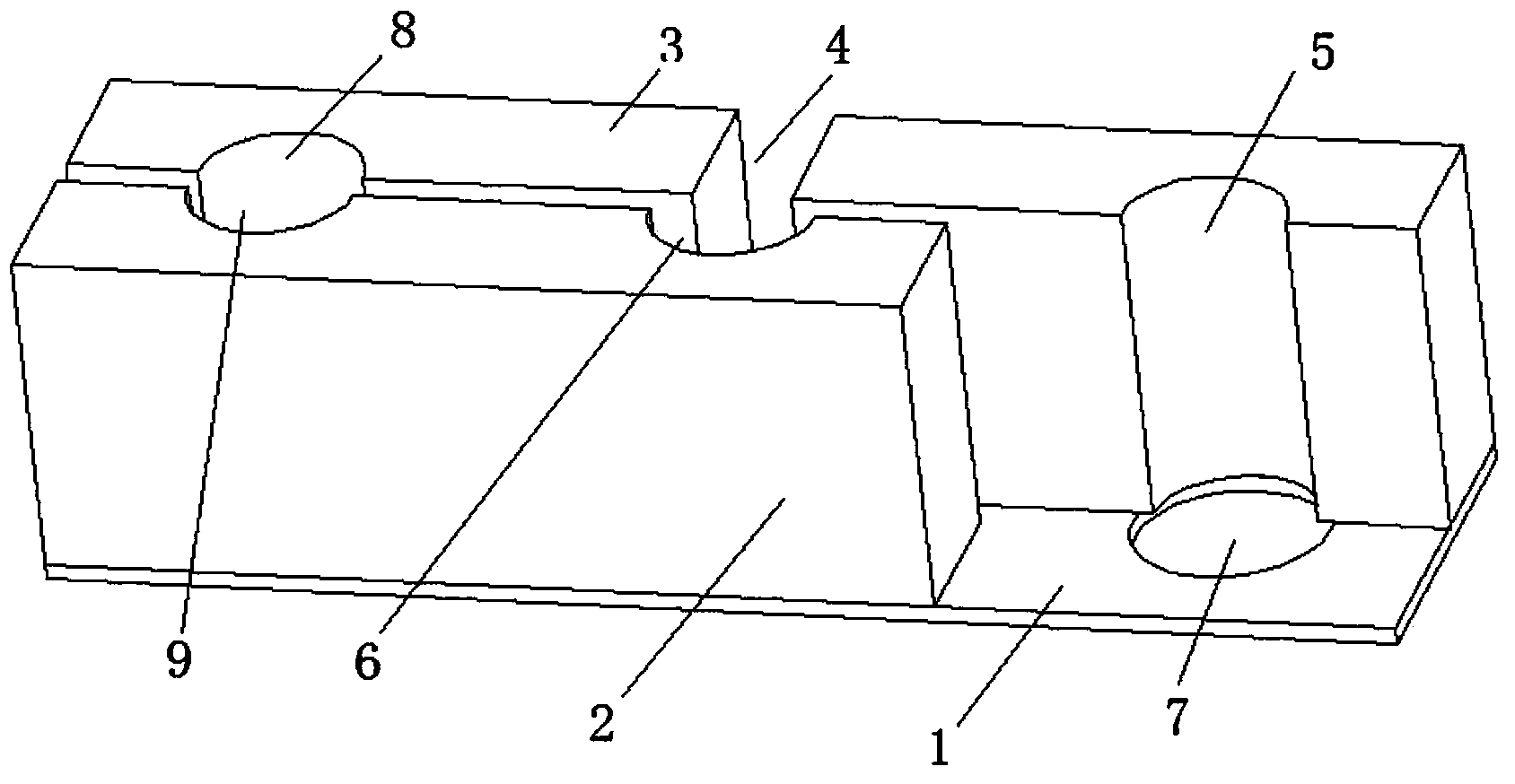

[0030] The sliding loading mechanism in this embodiment includes a bottom plate 1, a fixed block 3, a slider 2, an incoming material position sensor, a first blanking position sensor and a second blanking position sensor;

[0031] The fixed block 3 is arranged on the bottom plate 1, and the slider 2 is slidably arranged on the bottom plate 1; the fixed block 3 and the slider 2 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com