Dressing method of arc-shaped roller wheel

A circular arc and roller technology, which is applied in the field of dressing of circular arc rollers, can solve the problems such as the inability to meet the radial clearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

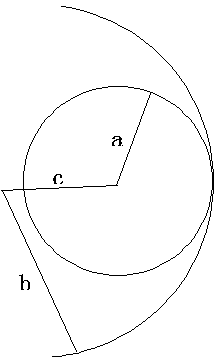

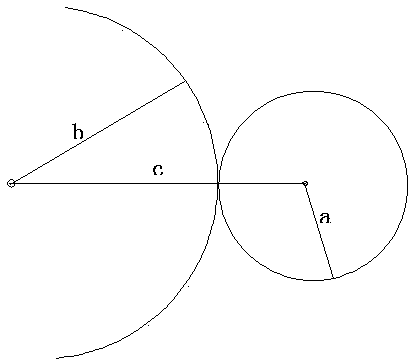

[0015] A method for trimming an arc-shaped roller, comprising a roller and a grinding wheel, the roller rotates along the rotation axis of the roller, the grinding wheel rotates along the rotation axis of the grinding wheel, the roller moves left and right along the rotation of the grinding wheel, and the rotation axis of the roller is located on the intersecting straight line of the rotation axis of the grinding wheel ; On the same plane, the distance between the midpoint of the grinding wheel shaft and the midpoint of the roller shaft is not greater than the sum of the distance from the midpoint of the roller shaft to the outer circle of the roller and the distance from the midpoint of the grinding wheel shaft to the outer circle of the grinding wheel. Such as figure 2 As shown, when the roller being trimmed is a convex surface, the distance c between the midpoint of the grinding wheel shaft and the midpoint of the roller shaft is equal to the sum of the distance b from the ...

Embodiment approach 2

[0018] Specifically as in embodiment 1, the grinding wheel can also be fixed and the roller feed mode can be used for dressing. When the roller with slightly larger diameter will be trimmed, you only need to move the mobile turntable 4 to the right; when the roller with larger diameter will be trimmed, the position of the sliding crank 10 can be adjusted without changing the grinder.

[0019] The invention has long service life and small volume, can stably produce high-precision roller products in batches, has small dressing force during dressing, small wear of the dressing tool itself, and high dressing precision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com