Automatic pressure regulating controller for negative pressure system

An automatic pressure regulation and controller technology, which is applied in fluid pressure control, non-electric variable control, and electric fluid pressure control. Accuracy, stable operation and high adjustment precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

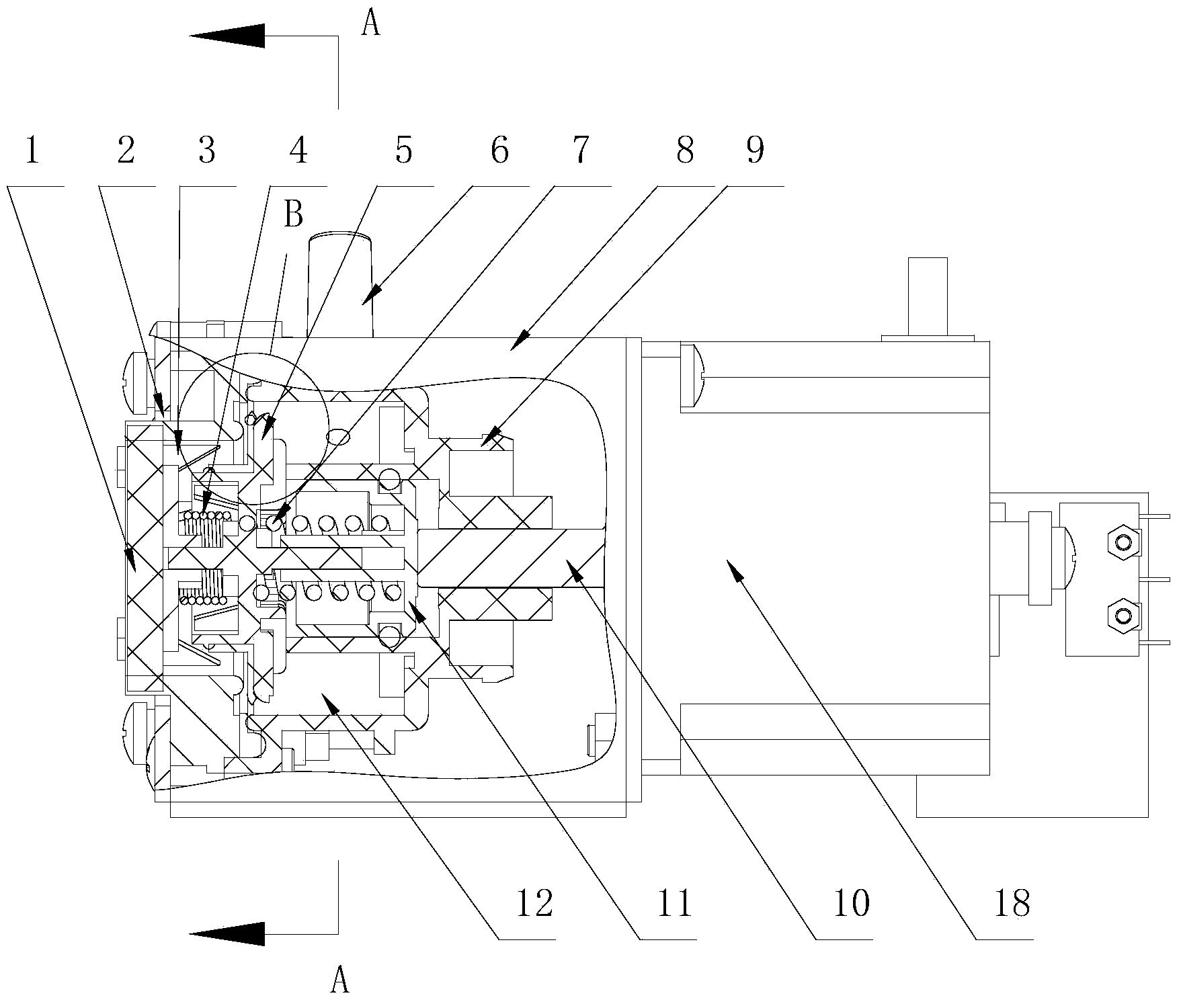

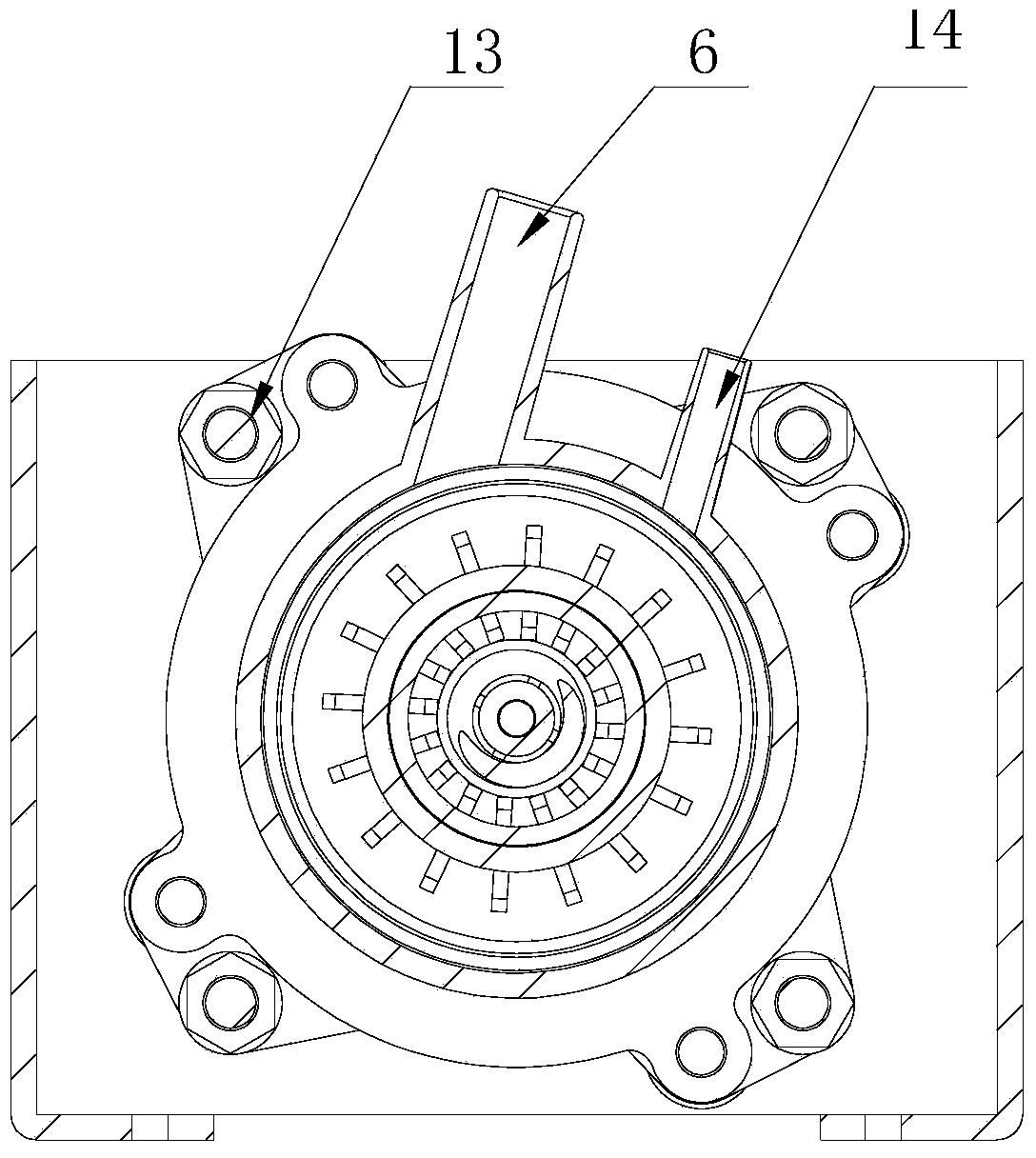

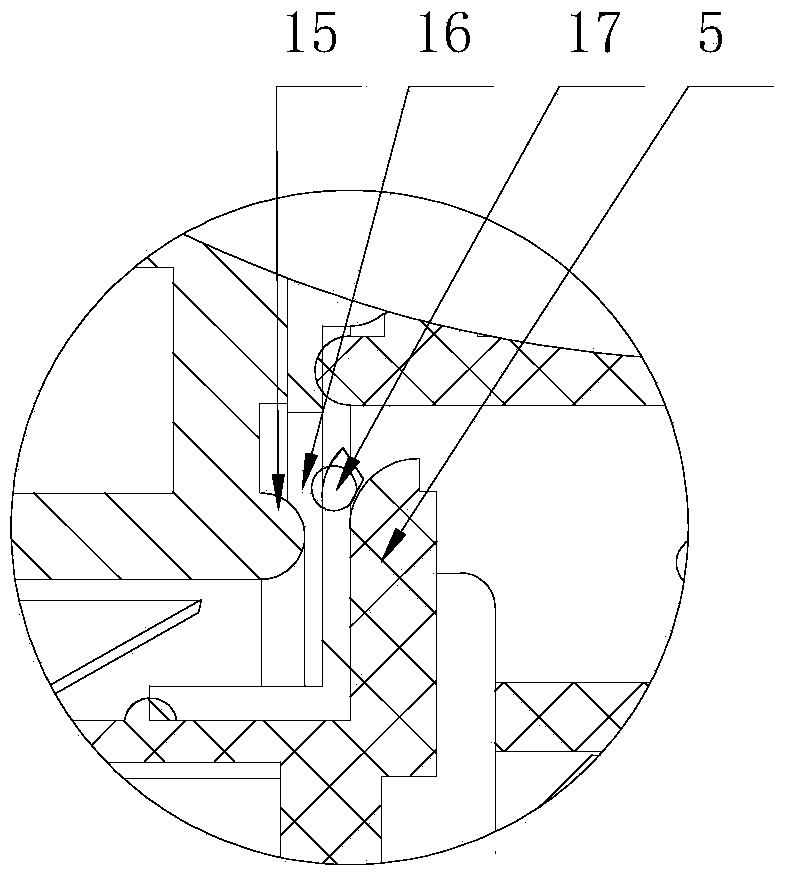

[0030] An automatic pressure regulating controller for a negative pressure system, which mainly consists of a housing 8, an end cover 2, a push rod 10, a negative pressure cover 9, a pressure plate 5, an outer compression spring 4, an inner compression spring 7, and a compression spring Cover 11 and push rod driving mechanism 18 constitute. The fixing screw 13 on the outer circumference of the end cover is fixedly installed on one side of the housing, and the ejector rod driving mechanism is fixedly installed on the other side outside the housing. The above-mentioned negative pressure cover is fixed in the casing, and the negative pressure cover is installed in sealing contact with the inner wall of the end cover to form a pressure regulating chamber 12 . A group of exhaust holes 3 evenly distributed on the circumference are formed on the end cover. A pressure plate is axially installed inside between the negative pressure cover and the end cover, and an external compression ...

Embodiment 2

[0034] The part of the motor shaft of the stepping motor located inside the housing is radially fixed with an inner contact switch plate 22, the outer end of the inner contact switch plate protrudes outside the housing, and the outer end of the contact switch plate is fixed outside the housing Limit switches 21 on both sides of the head. In this embodiment, the contact switch board has two symmetrical outer ends extending out of the housing, and two pairs of limit switches located at the two outer ends are installed on the housing. All the other are the same as in Example 1.

[0035] The working principle of the automatic pressure regulating controller used in the negative pressure system is as follows:

[0036] The negative pressure generated by the negative pressure pump is connected with the negative pressure interface through the rubber hose, so that the negative pressure chamber of the controller is filled with negative pressure. The stepping motor in the figure is a lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com