Transmissions and differentials as well as motor and transmission units

A technology of differentials and transmissions, which is applied in the direction of transmission components, transmission devices, vehicle gearboxes, etc., and can solve the problems of large structural space requirements and large structural space requirements of transmissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

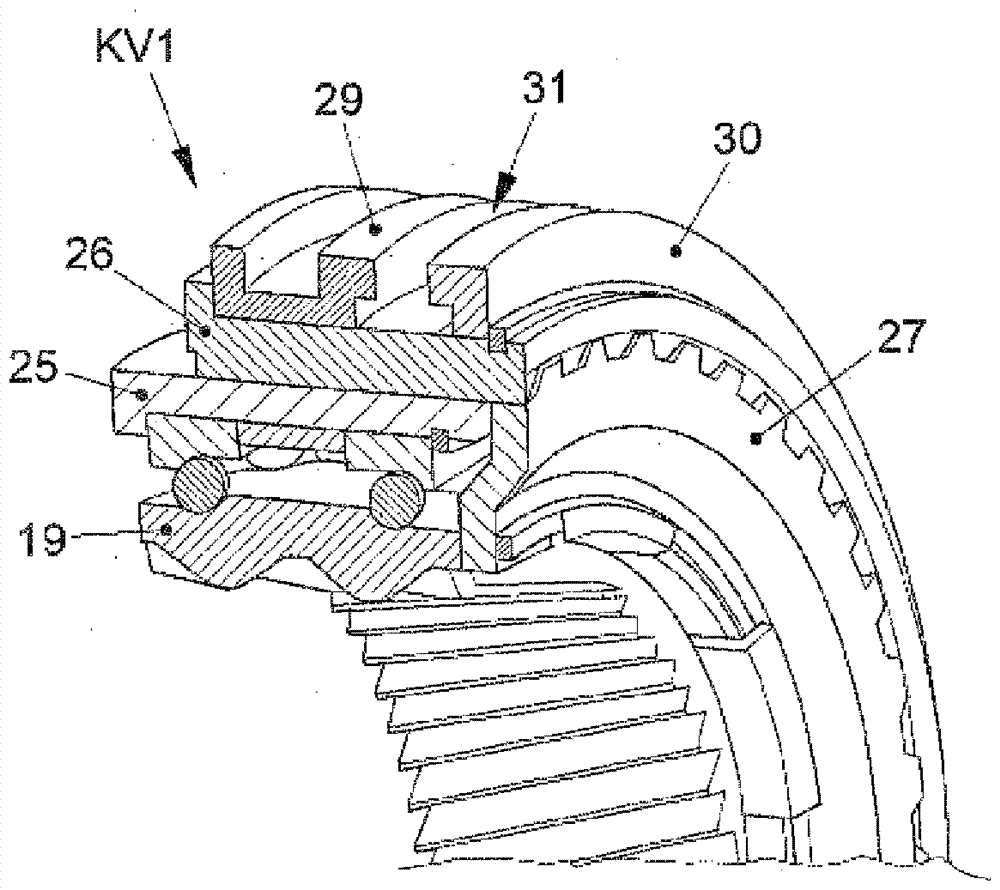

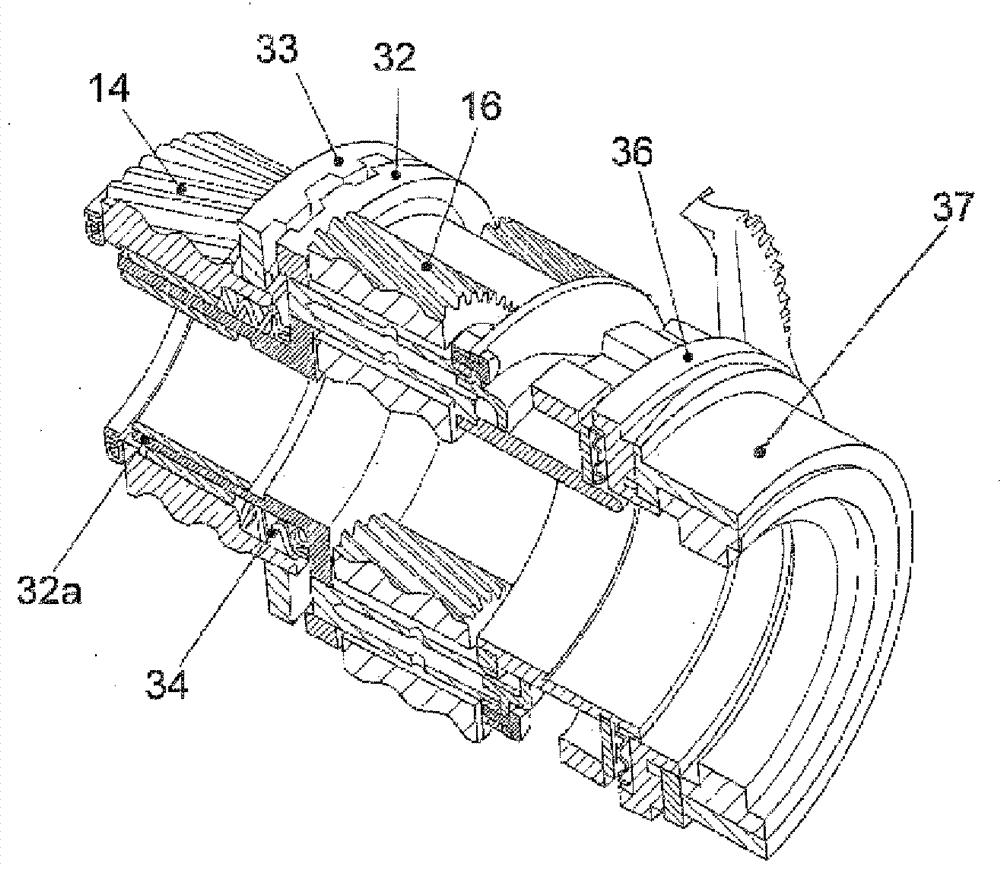

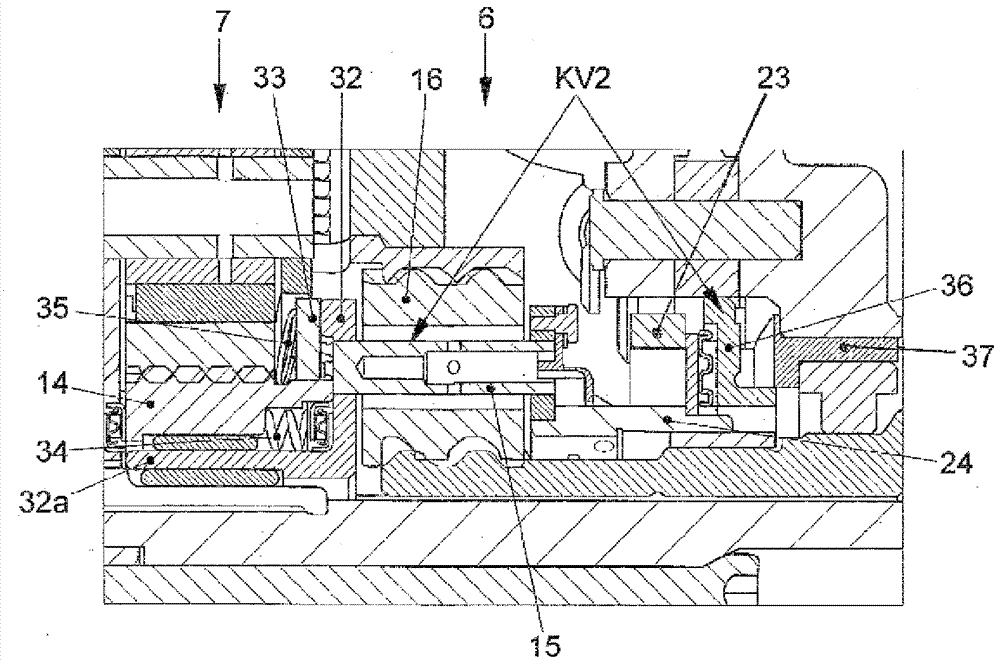

[0016] figure 1 and 2 First, the transmission and differential 1 is shown schematically with a housing not shown in detail here.

[0017] The transmission and differential 1 has an input shaft 2 and two output shafts 3 and 4 arranged coaxially with respect to the input shaft 2 . The transmission and differential 1 has a transmission section and a differential section in the form of a spur gear differential 5 . The transmission section, not further shown here, has two planetary gear stages, input stage 6 and load stage 7 .

[0018] here in here figure 1 In the usual "half view" shown in , the transmission and the corresponding elements of the differential 1 can be seen very well. Thus, in figure 1 and 2 Only the "upper half" of the per se rotationally symmetrical arrangement, ie the important rotating components of the transmission and differential 1 , is shown schematically in FIG. The drive unit shown here (ie the transmission and differential 1 shown here) is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com